| SKU | 7100228302 |

|---|---|

| Legacy SKU | 60440403420 |

| UPC | 00638060774618 |

| Product Number | 268XA |

3M Trizact Hookit Film Disc 268XA uses proprietary microreplication technology where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on a film backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.

- Proprietary 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Creates high gloss level for glass defect repair and solid surface finishing

- Micron sized abrasive pyramids produce a high-gloss finish

- Well suited for use on mini random orbital sanders to produce a polish-ready finish

- Produces finer finishes than paper and film-backed abrasives

Product Dimensions |

Imperial | Metric |

| Weight | 3.573 lbs | |

|---|---|---|

| Width | 12-1/2 in | |

| Length | 12-1/2 in | |

| Height | 2.6 in | |

| Diameter | 11 in | 279.4 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 7.682 lb |

|---|---|

| Length | 12.9 in |

| Width | 13 in |

| Height | 5.6 in |

| Maximum Speed | 2,000 rpm |

|---|

PRODUCT FAQ

-

What is the diameter of the 3M™ Trizact™ Hookit™ Film Disc 268XA?

The diameter of this disc is 11 inches.

-

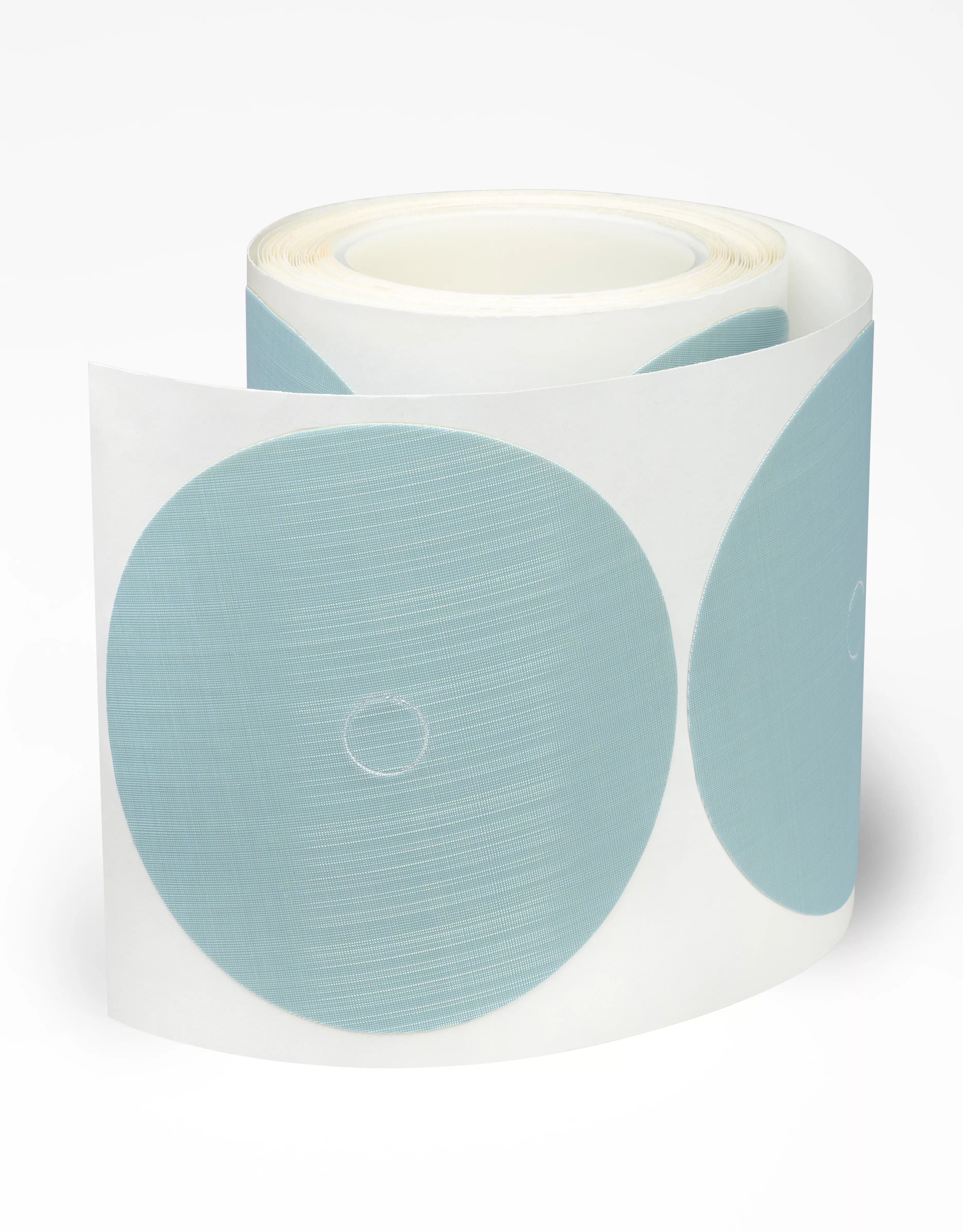

How many discs are included in one carton and case of this product?

There are 50 discs per carton and 100 discs per case for this product.

-

What grit size is the A5 Mic classification equivalent to for sandpaper?

The A5 Mic classification is approximately equivalent to a P3000-P5000 grit sandpaper.

-

. Can you explain what "Die 1100F" refers to on the packaging label?

. Die cutting refers to using a press or machine tool within manufacturing processes, used to cut apart materials ranging from paper, plastics, fabric and more -- in reference here most likely reflective film material. In context, references die identification number as it applies specifically when a die goes through high temperatures along with pressure-sensitive adhesive products increasing difficulty enduring any adhesive labels over time etc.

Compared to conventional abrasive products, 3M™ Trizact™ abrasives offer a finer finish, faster results, and longer-lasting performance. The 3M™ Trizact™ Hookit™ Film Disc 268XA is a versatile option suitable for use on a variety of solid surfaces and topcoats, accommodating most finish and process requirements. It features the 3M™ Hookit™ attachment system, allowing for quick mounting and removal and secure placement during use. Hookit™ discs attach firmly to a hook-and-loop backup disc pad (sold separately) on rotary or random orbital tools, can be removed cleanly and easily, and can be re-used for the life of the disc. This disc can be used wet or dry.

3M™ Trizact™ discs differ from conventional abrasives in that they start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality. They are designed to last longer than conventional discs and provide precise finish control, reducing grade sequences and requiring fewer process steps and abrasive products. Three-dimensional structures uniformly distributed over the entire surface ensure consistent performance and eliminate disc-to-disc variation.

The 3M™ Trizact™ Hookit™ Film Disc 268XA uses an aluminum oxide abrasive mineral. Aluminum oxide is a popular choice among industrial professionals due to its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.