| SKU | 7000119187 |

|---|---|

| Legacy SKU | 60440227951 |

| UPC | 00051141274911 |

| Product Number | 268XA |

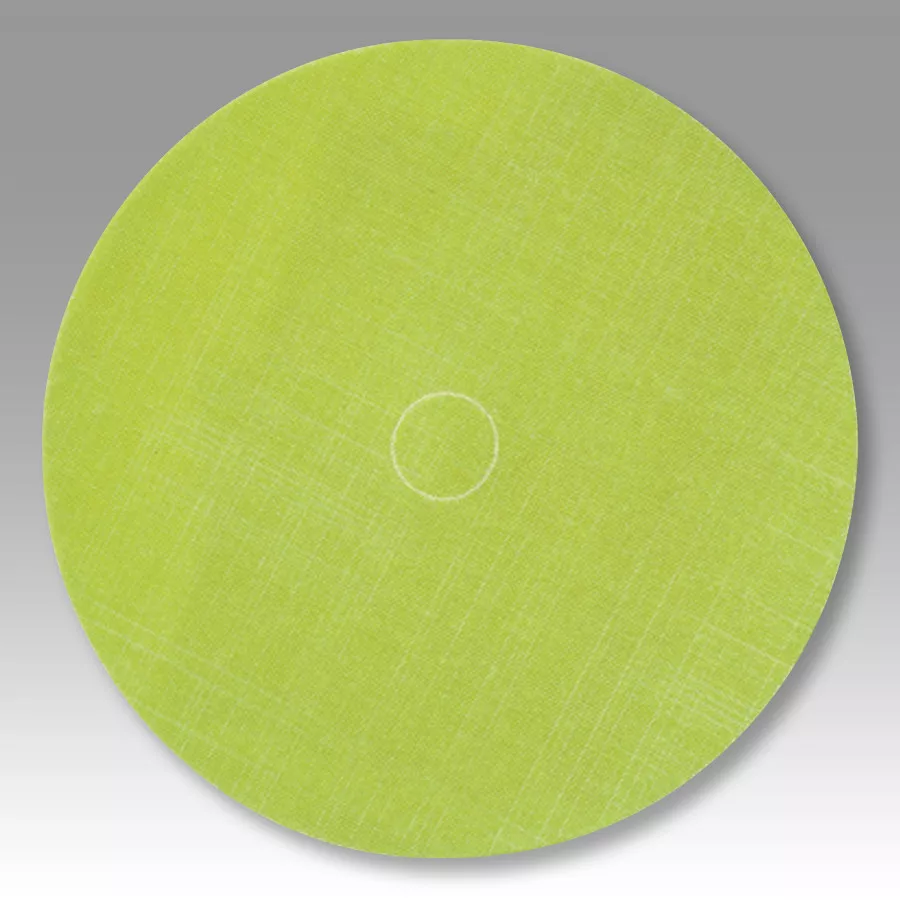

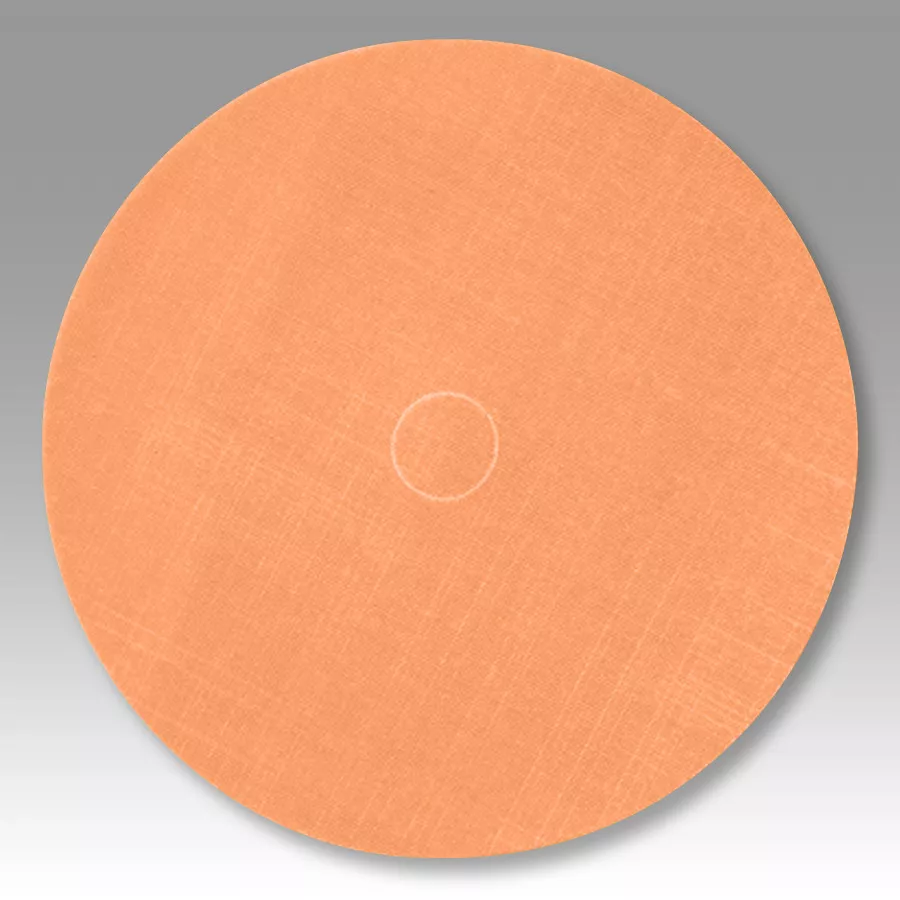

3M Trizact Hookit Film Disc 268XA uses proprietary microreplication technology where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on a film backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.

- Proprietary 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Creates high gloss level for glass defect repair and solid surface finishing

- Micron sized abrasive pyramids produce a high-gloss finish

- Well suited for use on mini random orbital sanders to produce a polish-ready finish

- Produces finer finishes than paper and film-backed abrasives

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 2.10409 lb |

|---|---|

| Length | 8.8189 in |

| Width | 6.69291 in |

| Height | 6.88976 in |

| Color | Blue |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Trizact™ Hookit™ Film Disc 268XA used for?

The 3M™ Trizact™ Hookit™ Film Disc 268XA is designed to provide consistent and precise finishes on a wide range of surfaces. It is mainly used in automotive repair applications, but it can also be used in industrial finishing and woodworking.

-

What does A10 signify in the product description?

A10 refers to grit size or abrasive grade. In this context, "A" stands for aluminum oxide abrasive material, while "10" indicates that it falls within a specific range of grit sizes (between P1000-P1200).

-

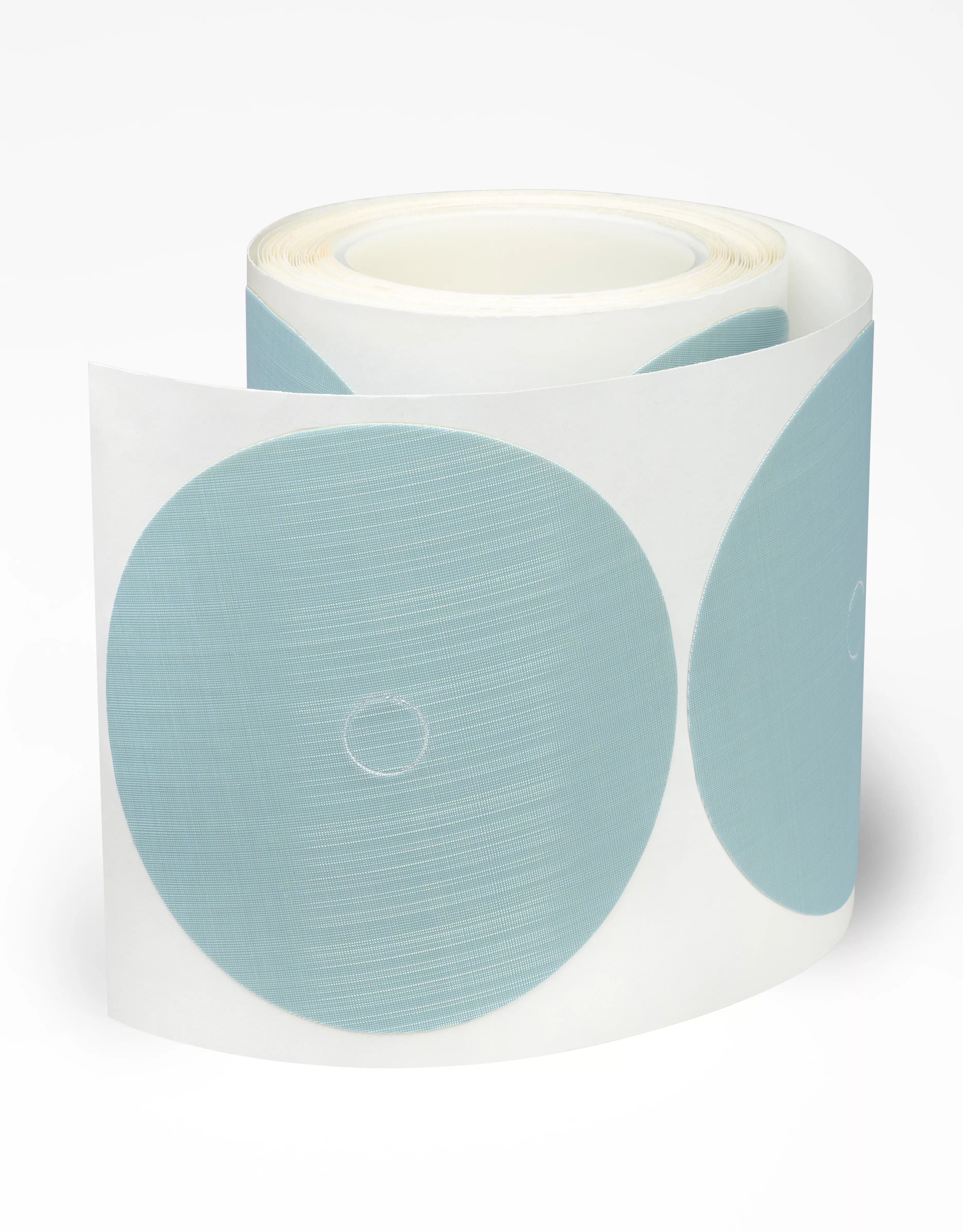

How many discs come in each package and case?

Each inner pack contains 25 discs of the 3M™ Trizact™ Hookit™ Film Disc 268XA. There are four inner packs per case for a total quantity of one hundred (100) discs per case.

-

What is NH and Die 600Z mentioned along with disc dimensions stand for?

NH stands for "no hole," which means that there are no holes present on the disc surface. Die/Molded/Resin Fiber products enable faster transitions between abrasives as they resist tearing due to thickness built up by processed parts throughout its life cycle. The number code attached at last signifies how much depth retaining power does hook-and-loop backing hold; here die-600z indicates strong depth retention capability allowing usages over curved or contoured surfaces without any worry about misalignment when pressure added during operation - makes it an ideal match with random orbital sanders prevalent among auto-repair professionals today!

Compared to conventional abrasive products, 3M™ Trizact™ abrasives offer a finer finish, faster results, and longer-lasting performance. The 3M™ Trizact™ Hookit™ Film Disc 268XA is a versatile option suitable for use on a variety of solid surfaces and topcoats, accommodating most finish and process requirements. It features the 3M™ Hookit™ attachment system, allowing for quick mounting and removal and secure placement during use. Hookit™ discs attach firmly to a hook-and-loop backup disc pad (sold separately) on rotary or random orbital tools, can be removed cleanly and easily, and can be re-used for the life of the disc. This disc can be used wet or dry.

3M™ Trizact™ discs differ from conventional abrasives in that they start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality. They are designed to last longer than conventional discs and provide precise finish control, reducing grade sequences and requiring fewer process steps and abrasive products. Three-dimensional structures uniformly distributed over the entire surface ensure consistent performance and eliminate disc-to-disc variation.

The 3M™ Trizact™ Hookit™ Film Disc 268XA uses an aluminum oxide abrasive mineral. Aluminum oxide is a popular choice among industrial professionals due to its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.