| SKU | 7010365284 |

|---|---|

| Legacy SKU | 61500159878 |

| UPC | 00048011930428 |

| Product Number | X3-WL |

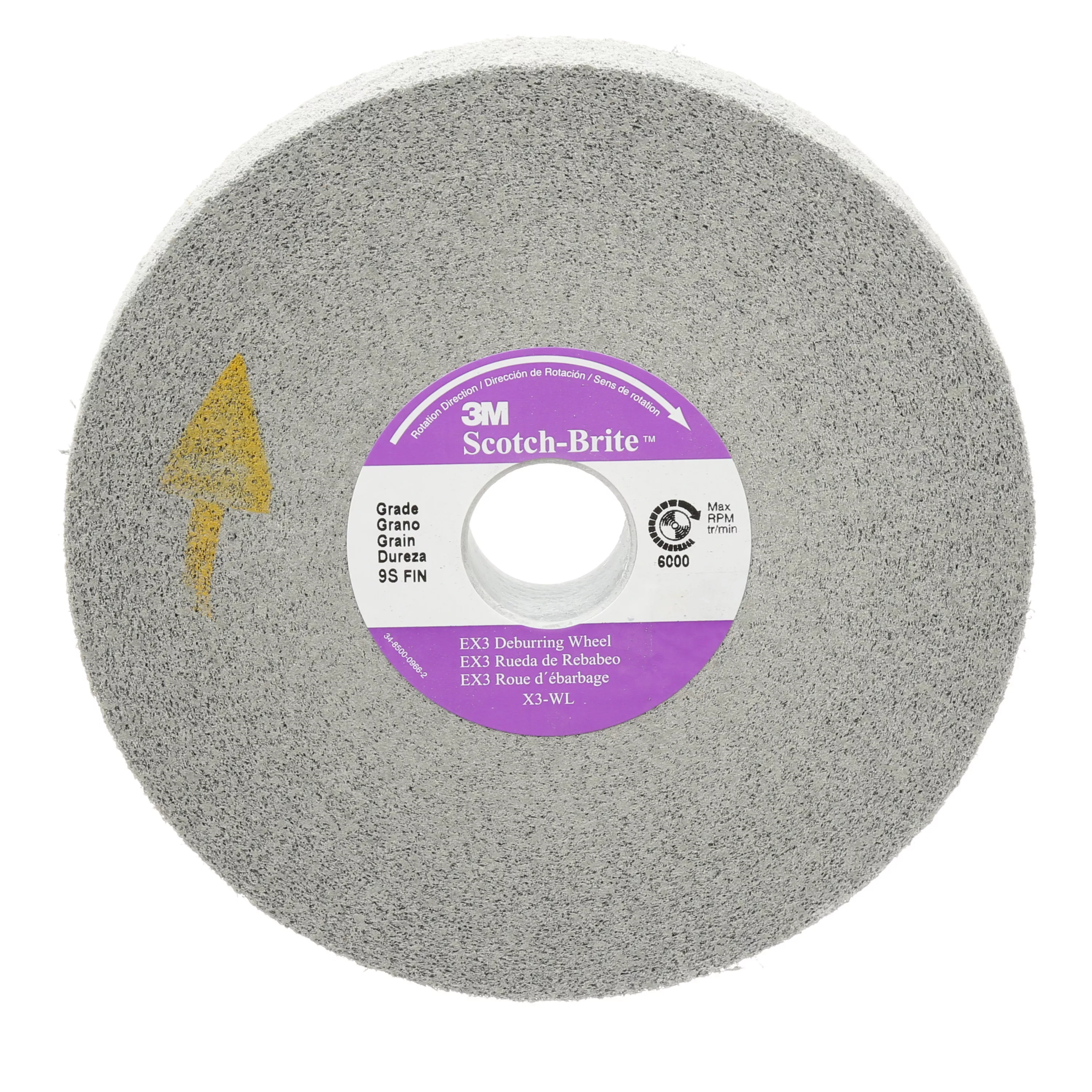

Scotch-Brite EX3 Deburring Wheel is a convolute-constructed, hard, durable deburring wheel suited for applications where edge retention is a must. The wheel performs best when consistently presented with a sharp edge or metal burrs. A unique resin system resists smearing and heat buildup.

- Highest edge retention and durability in the Scotch-Brite™ Deburring Wheel line provides aggressive edge deburring

- Specially engineered to condition sharp edges and metal burrs

- Convolute construction provides a balanced, smooth running wheel throughout product life

- Non-woven web runs cool and lessens impact on heat-sensitive materials

- Unique resin system produces less smearing, reducing clean and prep time

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 10 in | 254 mm |

| Center Hole Diameter | 5 in | 127.0 mm |

Shipping Dimensions |

|

| Weight | 4.99788 lb |

|---|---|

| Length | 10.5 in |

| Width | 10.5 in |

| Height | 1.7 in |

| Color | Gray |

|---|---|

| Maximum Speed | 3,600 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ EX3 Deburring Wheel used for?

The Scotch-Brite™ EX3 Deburring Wheel is designed to remove sharp edges, burrs and fine finishes from your metal parts.

-

Is it easy to use and install?

Yes, it's very easy! Simply attach the deburring wheel to your bench grinder or polishing machine like any other abrasive wheel.

-

How long does this deburring wheel last compared to others on the market?

Our product has a longer life span than traditional abrasives. It delivers consistent results throughout its lifespan, making it a cost-effective option in the long run!

-

Does this deburring wheel have warranty coverage?

3M offers guarantee coverage against defects in materials or workmanship provided that we are notified within 30 days of purchase. You can learn more about our warranty policy by contacting one of our representatives!

-

Are there different grades available? Which grade would be best suited for my project needs?

The Scotch-Brite™ EX3 Deburring Wheel comes with different grades ranging from coarse to ultra-fine finishing. For professional applications requiring precision finishes on harder metals such as stainless steel, bronze or aluminum, we recommend trying X4 (Ultra Fine) or X5 (Finer Finishing). We suggest using our coarser options if you need an aggressive grinding experience without damaging your material!

Scotch-Brite™ EX3 Deburring Wheel is an effective tool for deburring, blending, finishing, and polishing edges on various materials such as glass, hard and soft composites, and metals including builder's hardware, medical instruments, metal fabrication, metal implants, plumbing fixtures, and turbine engines. However, it is not recommended for applications where conformability and finishing of flat surfaces are required due to its hard density.

The EX3 Deburring Wheel is available with either silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. On the other hand, aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Scotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

- Effective for deburring, blending, finishing, and polishing edges on various materials

- Available with silicon carbide or aluminum oxide abrasive mineral

- Silicon carbide produces a finer finish while aluminum oxide provides high cut-rate and long life

- Scotch-Brite™ industrial abrasives incorporate abrasives into non-woven nylon or synthetic fibers for consistent results

- The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers