| SKU | 7010291331 |

|---|---|

| Legacy SKU | 61500297967 |

| UPC | 00048011646909 |

| Product Number | X3-WL |

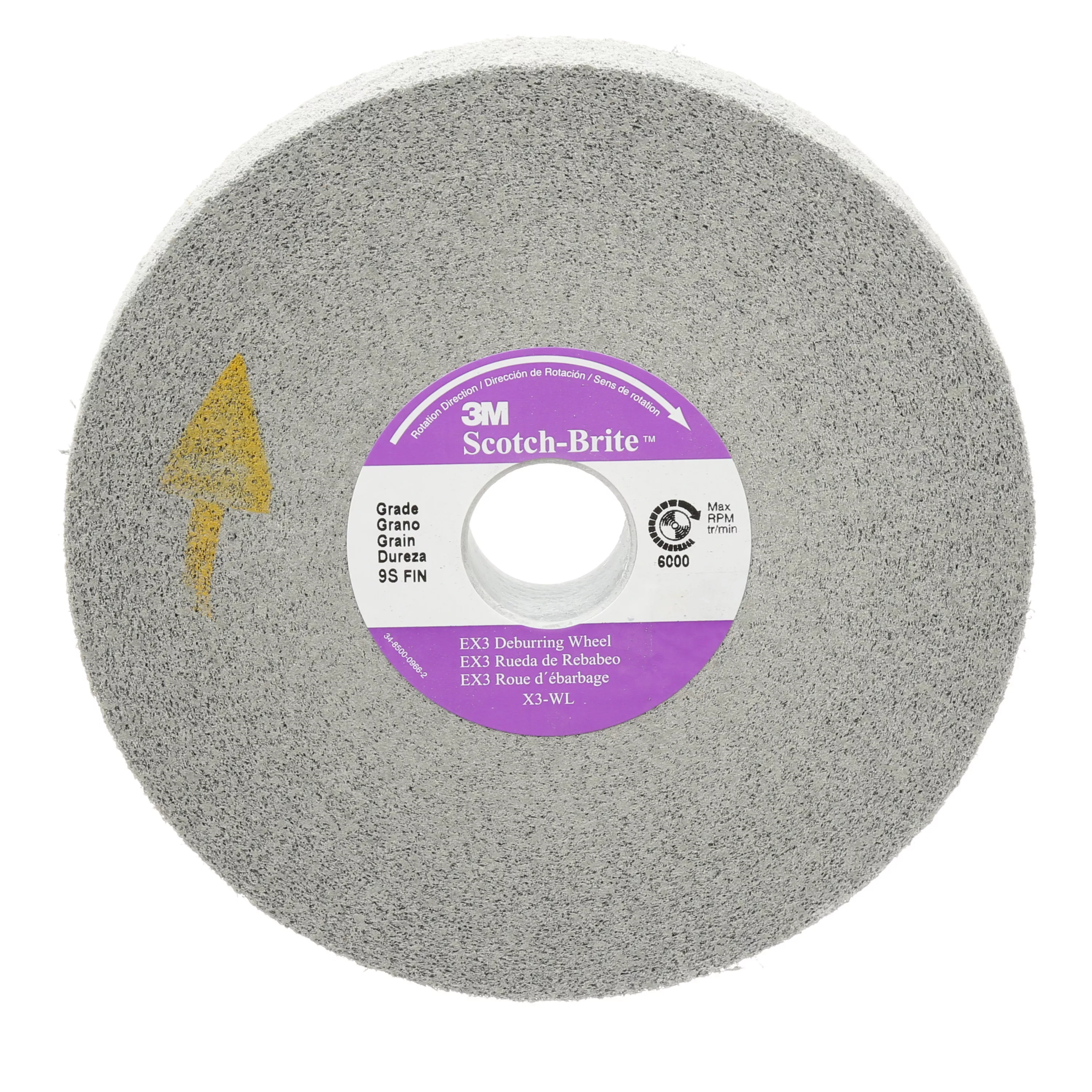

Scotch-Brite EX3 Deburring Wheel is a convolute-constructed, hard, durable deburring wheel suited for applications where edge retention is a must. The wheel performs best when consistently presented with a sharp edge or metal burrs. A unique resin system resists smearing and heat buildup.

- Highest edge retention and durability in the Scotch-Brite™ Deburring Wheel line provides aggressive edge deburring

- Specially engineered to condition sharp edges and metal burrs

- Convolute construction provides a balanced, smooth running wheel throughout product life

- Non-woven web runs cool and lessens impact on heat-sensitive materials

- Unique resin system produces less smearing, reducing clean and prep time

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 12 in | 304.8 mm |

| Center Hole Diameter | 5 in | 127.0 mm |

Shipping Dimensions |

|

| Weight | 3.49874 lb |

|---|---|

| Length | 12.4 in |

| Width | 12.4 in |

| Height | 2.6 in |

| Color | Gray |

|---|---|

| Maximum Speed | 3,000 rpm |

PRODUCT FAQ

-

What is the size of the Scotch-Brite™ EX3 Deburring Wheel, 12 in x 3/8 in x 5 in, 9S FIN, 10 ea/Case, SPR

24200A?

-

The size of the Scotch-Brite™ EX3 Deburring Wheel is a diameter of 12 inches and a width of both face and arbor hole are at .375 inches while its height measures at five (5) inches.

Can I use this deburring wheel on aluminum materials?

-

Yes! This wheel can be used for aluminum along with other soft metals such as brass or copper. It's also great to have non-woven features that don't create any metal contamination when being used.

Is it possible for me to purchase only one instead of an entire case?

-

Unfortunately, no. These wheels come pre-packaged as ten (10) per case to provide a more cost-effective option since these wheels tend to be heavy-duty materials which might require frequent replacements.

How long does it take before the abrasive mineral wears down?

-

There really isn't an exact timeline for how long until the material wears down--that all depends on how frequently you'll be using your wheel and what materials will come into contact with them. Generally speaking though- customers love their longevity c

Scotch-Brite™ EX3 Deburring Wheel is an effective tool for deburring, blending, finishing, and polishing edges on various materials such as glass, hard and soft composites, and metals including builder's hardware, medical instruments, metal fabrication, metal implants, plumbing fixtures, and turbine engines. However, it is not recommended for applications where conformability and finishing of flat surfaces are required due to its hard density.

The EX3 Deburring Wheel is available with either silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. On the other hand, aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. Although silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Scotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

- Effective for deburring, blending, finishing, and polishing edges on various materials

- Available with silicon carbide or aluminum oxide abrasive mineral

- Silicon carbide produces a finer finish while aluminum oxide provides high cut-rate and long life

- Scotch-Brite™ industrial abrasives incorporate abrasives into non-woven nylon or synthetic fibers for consistent results

- The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers