| SKU | 7100214174 |

|---|---|

| Legacy SKU | 61500334067 |

| UPC | 00638060761939 |

| Product Number | PB-FB |

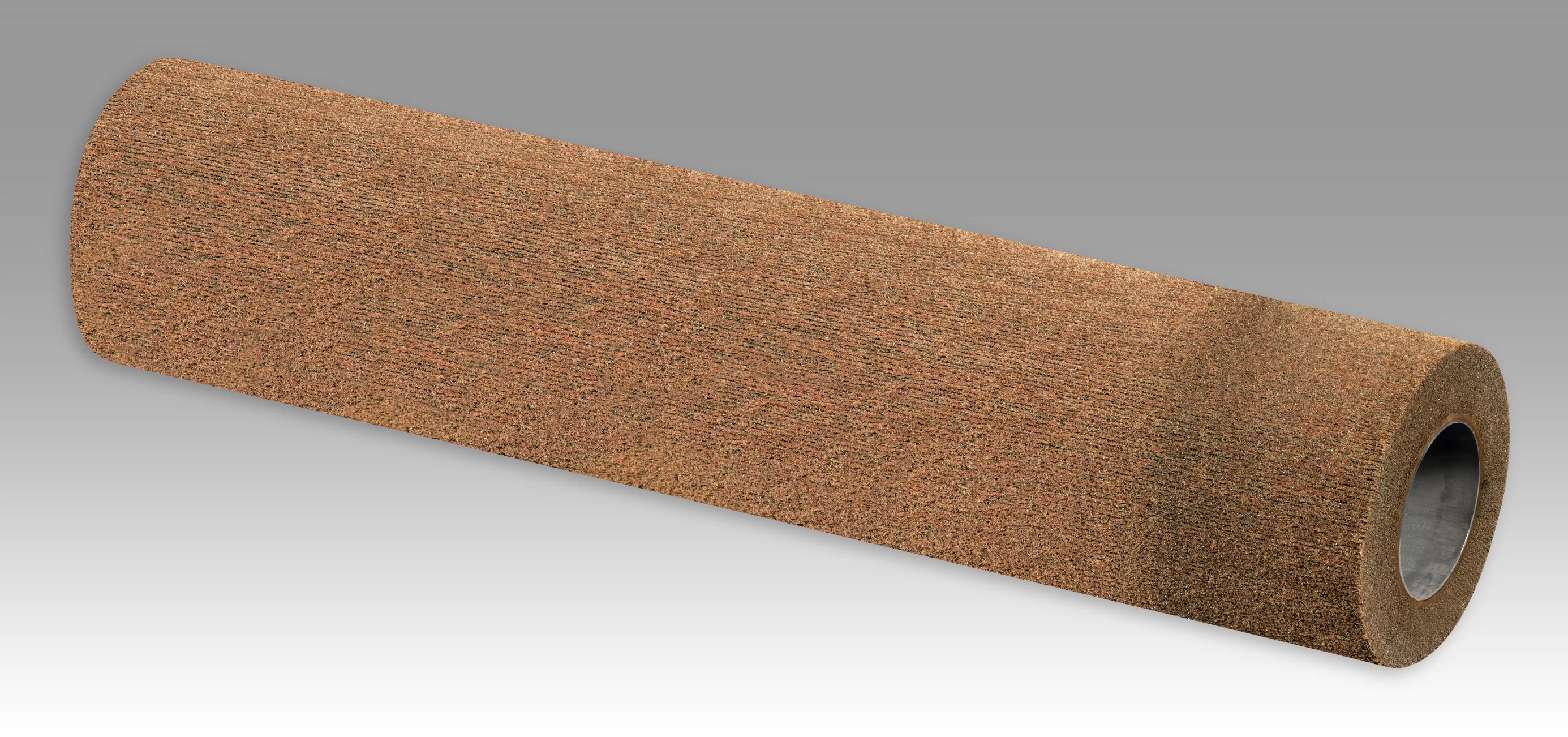

Scotch-Brite High Strength Premium Blend and Finish Flap Brush is one of 3M's best-performing flap brushes. It provides greater durability, longer life and exceptional finish, while running soft, smooth and smear free.

- Flap construction helps minimize chatter risk

- Available in a variety of grades, so operators can choose the right brush for their unique application

- Aluminum Oxide mineral cuts sharp but leaves a soft scratch pattern

- Open web is spongy and responsive, minimizing risk of altering part geometry

- Open web is load resistant, helping to prolong abrasive service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 0.88097 lb |

|---|---|

| Length | 8.62205 in |

| Width | 8.62205 in |

| Height | 2.6378 in |

PRODUCT FAQ

-

What are the dimensions of the 3M Scotch-Brite™ High Strength Premium Blend and Finish Flap Brush, PB-FB?

The brush measures 4-1/2 in x 2 in with a thread size of 5/8 in-11.

-

What is the recommended application for this flap brush?

The 7A coarse grit level makes it ideal for working with stainless steel, aluminum and other metals to remove rust or surface coatings.

-

How many brushes come per case?

Each order comes packaged as one unit per case.

The Scotch-Brite™ High Strength Premium Blend and Finish Flap Brush is designed with individual sheets of abrasive material adhered to a fiberglass core at a 90 degree angle. The brush minimizes chatter risk under normal use and eliminates residual traces or marks left by singular discs or discs ganged on a shaft. The brush may be used with a variety of tools, including backstand, match and finish sander and a centerless grinder.

Available in a Variety of GradesScotch-Brite™ High Strength Premium Blend and Finish Flap Brush combines aluminum oxide mineral and non-woven nylon fibers using resin. The mineral is available in a variety of grades, including CRS, MED and VFN. A coarser grade is desirable when operators seek a more aggressive cut, while a very fine grade is desirable when a softer scratch is desirable. The brush is also offered in Type L (Lofty), which means it has additional layers of web for maximum conformability and consistency.

Regardless of the grade chosen, operators will get the same level of consistency and responsiveness they've come to expect from Scotch-Brite™ abrasives. Each brush offers unique cleaning or finishing capabilities based on different grade and density combinations.

Common ApplicationsThe High Strength Premium Blend and Finish Flap Brush helps with blending finishes, deburring and antique finishing on hardware and plumbing fixtures. Scotch-Brite™ Flap Brushes are used by manufacturers of hand tools, surgical equipment, stamped metal parts, transportation vehicles, builders hardware, plastic products, mouldings and woodworking products. Aerospace component manufacturers condition surfaces of blades, vanes, rotors, fasteners, nozzles, extrusions and airframe supports. In maintenance and repair, Scotch-Brite flap brushes are used to clean and condition surfaces properly and efficiently.

Most common industrial grinding lubricants, coolants, and/or compounds can be used with Scotch-Brite™ flap brushes if necessary.

The Many Benefits of Open Web AbrasivesNon-woven technology makes Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products not only enhance productivity, but also increase operator safety by reducing the need for cleaning chemicals and pastes, and replacing wire brushes that can break off and cause injury. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.