| SKU | 7010367048 |

|---|---|

| Legacy SKU | 61500314002 |

| UPC | 00076308643393 |

| Product Number | PB-FB |

Scotch-Brite Premium Blend and Finish Flap Brush has all the benefits operators have come to expect from Scotch Brite products, but its heightened ability to cut aggressively sets this abrasive flap brush apart. It is even more durable than High Strength Scotch Brite products.

- Versatile brush deburrs and finishes in one step

- High-performance alternative to conventional wire brushes

- Thick open web enhances abrasive toughness and durability

- Open web resists loading, prolonging abrasive service life and contributing to a consistent cut

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 8 in | 203.2 mm |

Shipping Dimensions |

|

| Weight | 23.3668 lb |

|---|---|

| Length | 10.3 in |

| Width | 10.3 in |

| Height | 37.9 in |

| Color | Gold |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 3,200 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Premium Blend and Finish Type L Flap Brush, PB-FB, TS Red Core used for?

The Scotch-Brite™ Premium Blend and Finish Type L Flap Brush is designed to deburr and blend surface imperfections on a variety of metals.

-

How coarse is the 7A Coarse version of this flap brush?

The 7A Coarse version of the flap brush has an aggressive cut rate, making it suitable for heavy stock removal on surfaces that are difficult to grind.

-

Can you give me more information about the size specifications of this product?

Of course! This particular flap brush comes in a size measuring at 8 inches by 36 inches with a thickness of 2.95 inches. It also includes one unit per case.

Scotch-Brite™ Premium Blend and Finish Flap Brush is commonly used for aggressive finishing and mild cleaning and deburring. It cuts aggressively, but leaves an even, consistent finish in its wake. This flap brush produces fine finishes on tools like saw blades, as well as deburrs and finishes on parts like surgical tools and medical equipment trays. It enhances productivity by enabling operators to deburr and finish in one step.

The Anatomy of Flap BrushesThe Scotch-Brite™ Premium Blend and Finish Flap Brush is made by adhering individual sheets of abrasive material to a steel or fiberglass core at a 90 degree angle. Steel cores are 5.75" in diameter and the red cores are designed to fit flat finishing machines. Scotch-Brite™ Premium Blend and Finish Flap Brush is also categorized as "Type L." The thickness of Type L is approximately 4x thicker than regular Clean and Finish web, which enhances abrasive durability.

Under normal use (abiding by recommended RPMs), the brush minimizes chatter risk. As it spins, flaps rotate centrifugally and make continuous contact with the workpiece. By deflecting slightly and abrading the surface, the wide flaps eliminate the residual traces or marks that tend to be left by singular discs or discs ganged on a shaft. The brush may be used with a variety of tools, including backstand, match and finish sander and a centerless grinder.

Scotch-Brite™ Premium Blend and Finish Flap Brush incorporates coarse aluminum oxide mineral into the open web. Aluminum oxide is a popular synthetic mineral choice among industrial professionals because of its hardness, strength and durability.

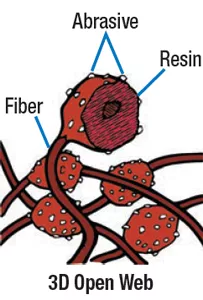

The Many Advantages of Scotch-Brite™ AbrasivesNonwoven technology makes Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity.

Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency and long service life. Scotch-Brite™ products may enhance productivity while reducing the need for cleaning chemicals and wire brushes. Scotch-Brite abrasives work fast and deliver consistent results, part after part.

- Aggressive finishing and mild cleaning and deburring

- Produces fine finishes on tools like saw blades

- Deburrs and finishes on parts like surgical tools and medical equipment trays

- Enhances productivity by enabling operators to deburr and finish in one step

- Minimizes chatter risk under normal use

- May be used with a variety of tools, including backstand, match and finish sander and a centerless grinder

- Nonwoven technology makes Scotch-Brite™ industrial abrasives unique

- Effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece

- Reduces rework and boosts productivity

- May enhance productivity while reducing the need for cleaning chemicals and wire brushes

- Works fast and delivers consistent results, part after part