| SKU | 7100017774 |

|---|---|

| Legacy SKU | 60070008770 |

| UPC | 00051111499993 |

| Product Number | 268L |

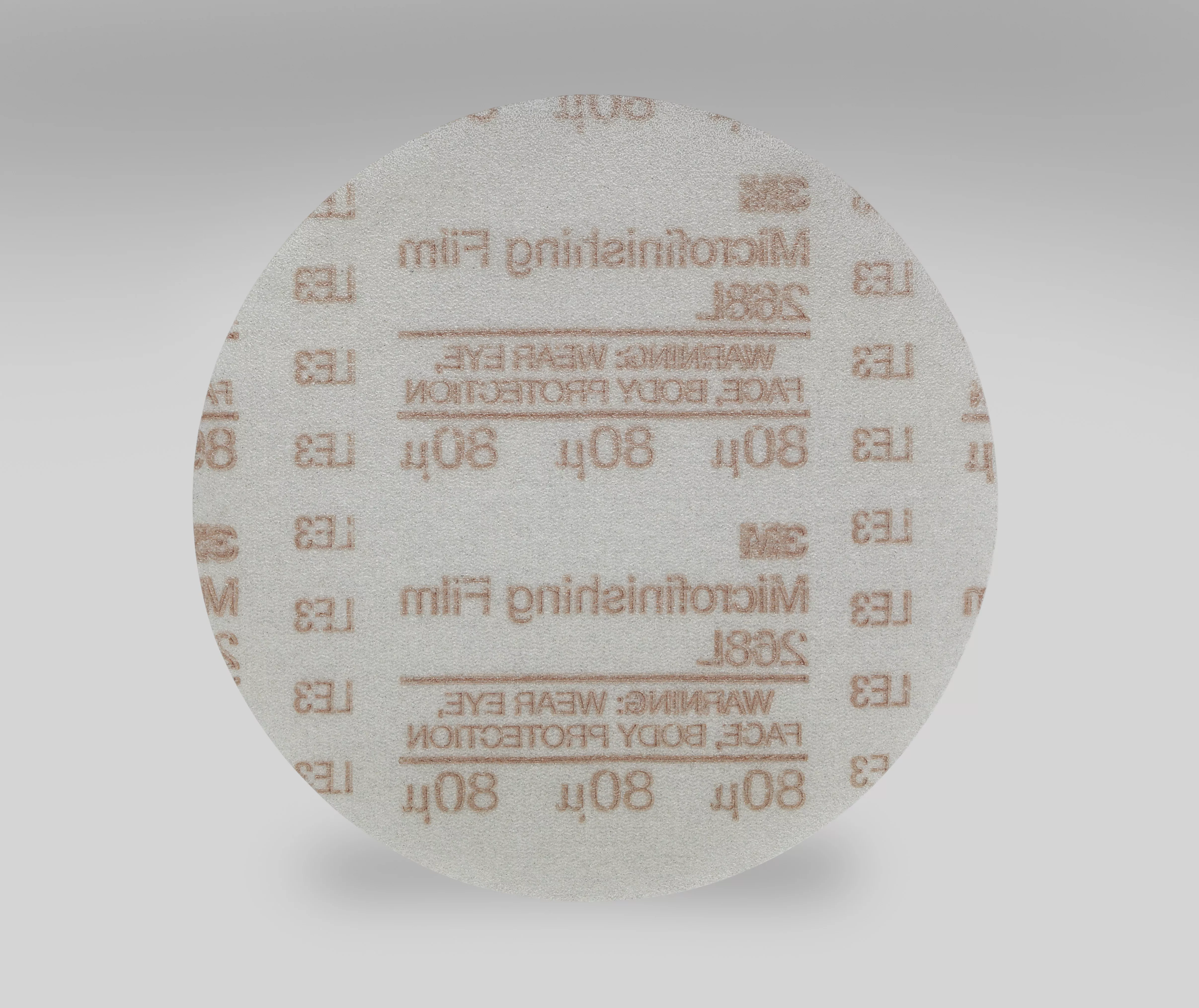

3M Microfinishing PSA Film Sheet 268L is a fast-cutting abrasive for precise, uniform, close-tolerance finishes. Aluminum oxide is resin-bonded to a 3 mil, high-strength polyester film backing that provides durability and flexibility for consistent finishing on contoured surfaces. The pressure sensitive adhesive (PSA) backing enables easy attachment to a sanding block. Use wet or dry.

- Provides precise, controlled, close-tolerance finishes

- High-strength film backing is tear resistant and can be run wet to reduce loading and airborne residue

- Precision, micron-graded aluminum oxide abrasive offers a fast cut, long life, and uniform finish on many substrates

- Flexible backing achieves consistent finishing on contoured surfaces

- PSA backing sticks easily but securely to sanding blocks, and is easily removed

- Ideal for sanding plastics, paint, e-coat and wood, as well as ferrous and non-ferrous metals

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 6.33609 lb |

|---|---|

| Length | 12.00787 in |

| Width | 12.00787 in |

| Height | 4.80315 in |

| Color | Green |

|---|

PRODUCT FAQ

-

What is the size of the 3M™ Microfinishing PSA Film Sheet 268L?

The size of the sheet is 8 1/2 inches x 11 inches.

-

How many sheets are included in one case of the product?

There are a total of 200 sheets per case.

-

What type of film is used in these sheets?

The type of film used is Type D, suitable for microfinishing applications.

-

What is the grit size or microns level for this product?

The product has a microns rating of 30, providing precise and fine finishing results.

Introducing the 3M Microfinishing PSA Film Sheet 268L, a revolutionary product designed to deliver precise and uniform finishes. This sheet features precision, micron-graded aluminum oxide that is resin-bonded to a high-strength, resilient polyester film backing. It is specifically engineered to provide a fast cut-rate and produce a consistent finish on a wide range of materials including wood, solid surface composites, plastic, fiberglass, metals, and paint preparation. The flexibility of the film backing allows for easy contouring, ensuring a uniform finish even on complex surfaces. Additionally, the polyester film backing offers superior tear-resistance compared to traditional paper products, making it the perfect choice for high-production environments.

The Convenience of Pressure Sensitive AdhesiveOur PSA film sheet is designed with convenience and productivity in mind. It features a light adhesive backing that attaches easily to a block or disc pad, just like a sticker. When it's time to remove the sheet, it does so cleanly, leaving behind a surface that is uncontaminated and ready for the next sheet. This adhesive backing eliminates the need for additional adhesives or clamps, saving you time and effort.

Fast Cut, Long LifeThe 268L film sheet is constructed with aluminum oxide, a popular choice among industrial professionals for its fast cut-rate and long life. This mineral is known for its toughness and durability, as it self-fractures to expose fresh cutting edges. Its fast cut-rate, hardness, and strength make it highly effective in sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys.

Run It Wet or DryOur film sheet can be used wet or dry, providing you with flexibility and versatility. When used with a coolant, such as water, the abrasive life is extended, the cut rate is increased, loading is prevented, and air-borne particles are reduced. Unlike other backing materials that may disintegrate when run wet, the high-strength film backing of our product maintains its strength and flexibility, ensuring consistent performance even in wet conditions.