| SKU | 7010365201 |

|---|---|

| Legacy SKU | 60650031895 |

| UPC | 00051144841745 |

| Product Number | 268L |

3M Hookit Microfinishing Film Disc 268L is a fast-cutting abrasive for precise, uniform, close-tolerance finishes. An aluminum oxide mineral is resin-bonded to a 3 MIL, high-strength polyester film backing for durability. This disc is ideal for defect repair and leveling, paint prep and final finishing.

- Micron-graded aluminum oxide delivers close tolerance precision finishes

- Water-resistant polyester film backing for wet or dry applications

- Hook and loop backing for easy tool attachment and re-use

- Color coded for ease of selection and reduced risk of error

- High-strength polyester film backing resin-bonded for durability

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 6.0001 lb |

|---|---|

| Length | 12.00787 in |

| Width | 12.00787 in |

| Height | 7.00787 in |

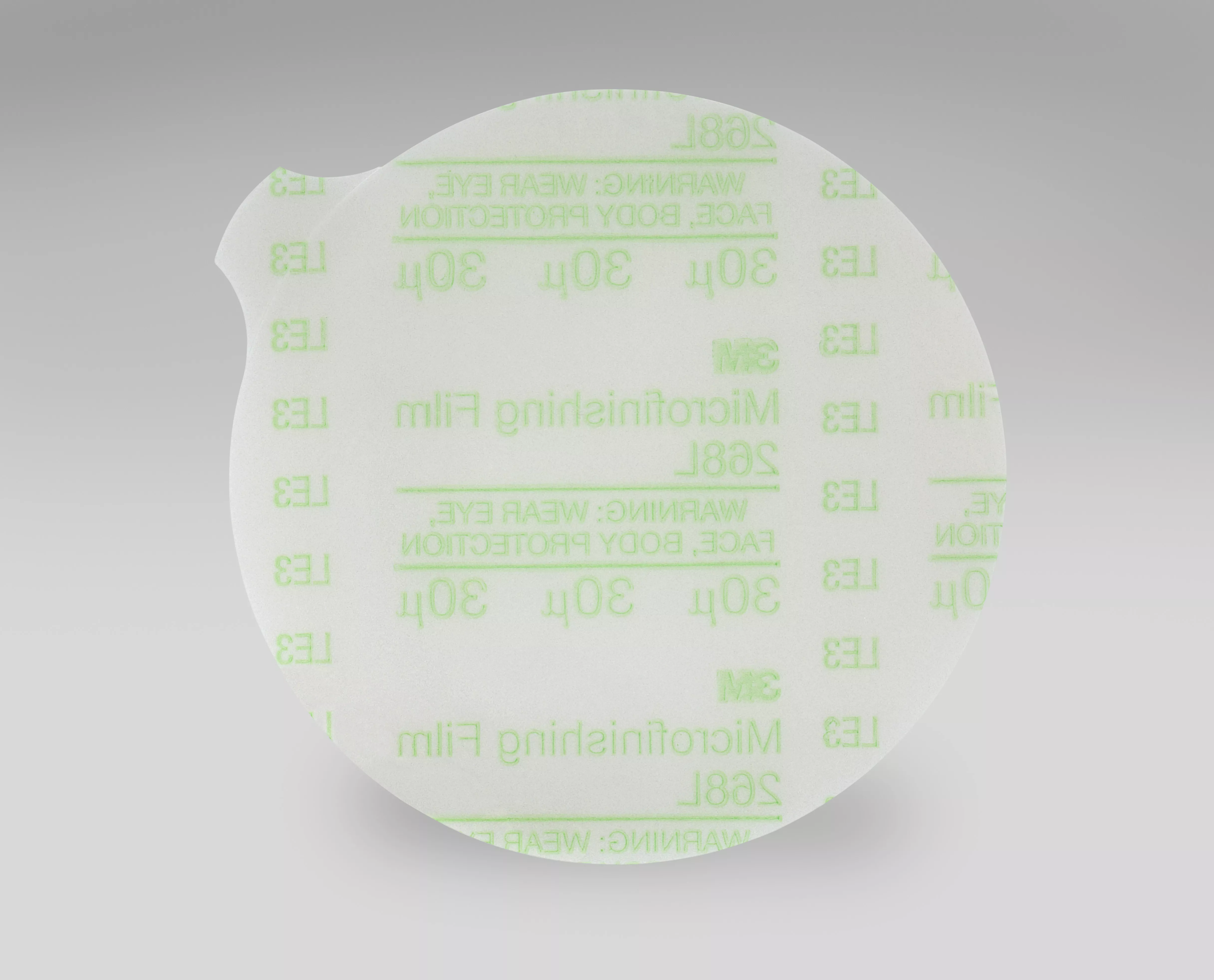

| Color | Green |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Hookit™ Microfinishing Film Disc 268L used for?

The 3M™ Hookit™ Microfinishing Film Disc 268L is commonly used in the automotive and aerospace industries to create a consistent, high-quality finish on surfaces.

-

How many discs come in a case of 3M™ Hookit™ Microfinishing Film Discs?

There are 500 discs per case of the 3M™ Hookit™ Microfinishing Film Discs.

-

What size are these microfinishing film discs?

These microfinishing film discs measure at a diameter of five inches by no hole (NH).

-

Can you tell me more about Type D classification on this product?

. "Type D" refers to the abrasive grade level that is affixed to each disc. In this particular product, it signifies an ultra fine grit - which means there's less friction during sanding ops making it ideal for finishing operations involving low roughness values.

-

. Why should I choose microfinsihing filim instead of other types of abrasives available in market ?

.Barriers occur when using traditional abrasives reduce productivity or create quality challenges like torn edges, scratch variability, gouging and undercutting .Whereas microfinishfilm uses advanced resin bonds & precise mineral grading techniques thus providing fast cutting action along with consisent leveled finish without any inconsistency keeping your products look professional and highly durable as ever.

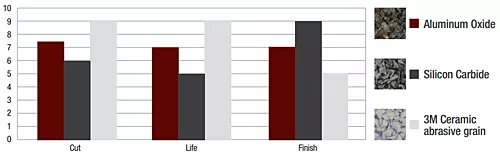

3M™ Hookit™ Microfinishing Film Disc 268L is designed to enable operators to achieve precise, controlled, close-tolerance finishes on surfaces from metals to plastics to wood. This product features precision, micron-graded aluminum oxide, resin-bonded to a high-strength, resilient polyester film backing. Aluminum oxide is desirable among industrial professionals for its fast cut-rate and long life.

Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys. It cuts aggressively without significantly altering part geometry, which is great for applications like finishing and paint prep – when you want to maintain the part's original shape.

Available in a wide range of grades, these discs are color coded for easy selection of grit and reduced risk of error.

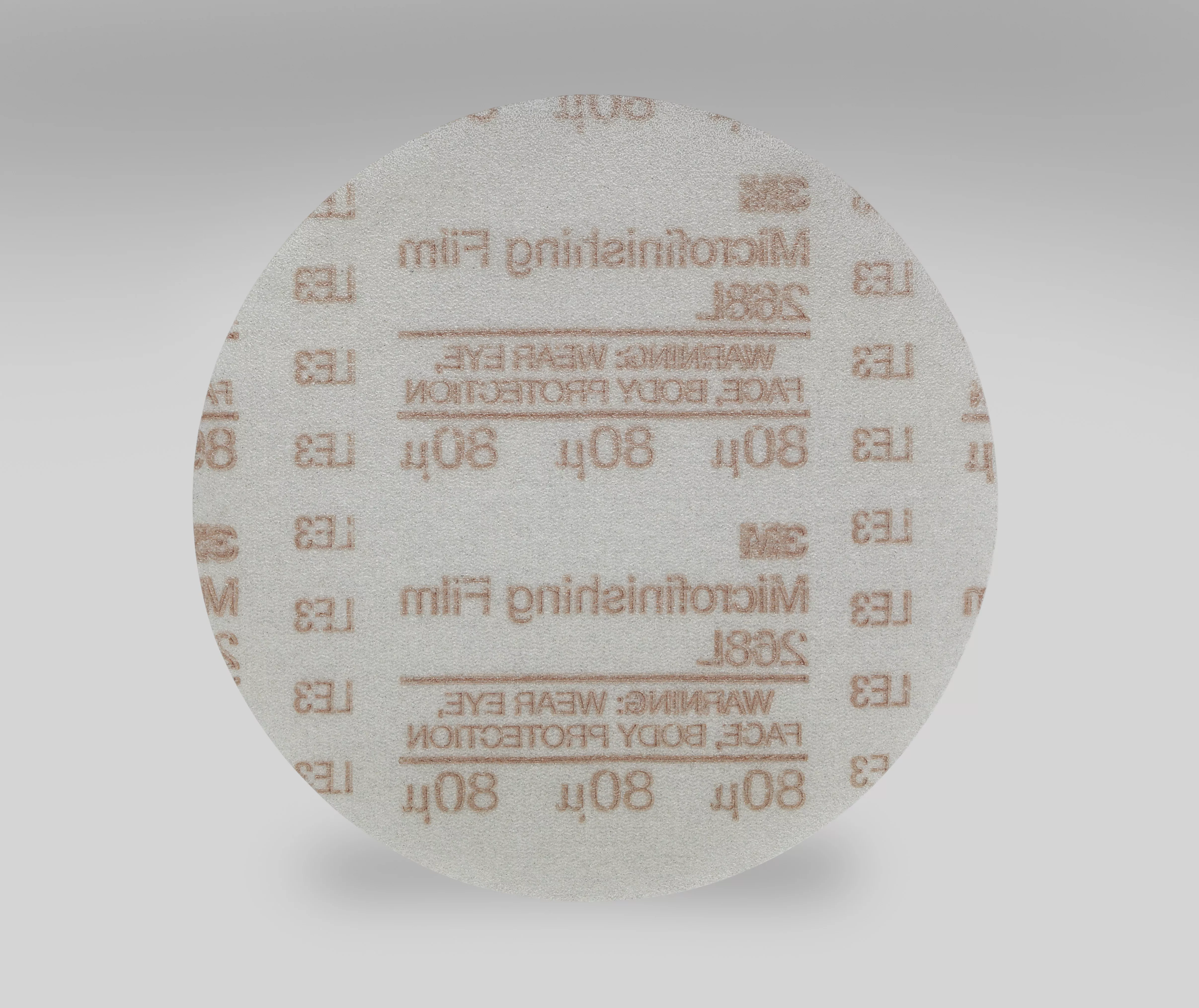

Run Wet or DryThese film-backed discs are water resistant, so they can be run wet or dry. Coolant generally extends abrasive life, increases cut rate and prevents loading. The high- strength, film backing maintains its strength and flexibility when paper will degrade when run wet, which makes it an excellent choice for use on a variety of woods and automotive applications.

Focus on the Task, Not the Tool with Hookit™ AttachmentMicrofinishing Film 268L utilizes 3M™ Hookit™ hook-and-loop attachment system which allows the operator to focus more on the task and less on tool. 3M™ Hookit™ products are manufactured with loop material that attaches to a backup pad (sold separately) where tiny hooks firmly engage the loops.

Attachment is quick, easy and secure. Sanding, finishing, and surface conditioning products with the hook-and-loop attachment and removal system are efficient for working through multi-step finishing processes and are ideal for environments where dust and debris is common. Abrasive products with a Hookit™ attachment can be used again and again for the life of the abrasive, unlike pressure-sensitive adhesive attachments.