| SKU | 7010328802 |

|---|---|

| Legacy SKU | 60870004938 |

| UPC | 00051144819898 |

| Product Number | 741A |

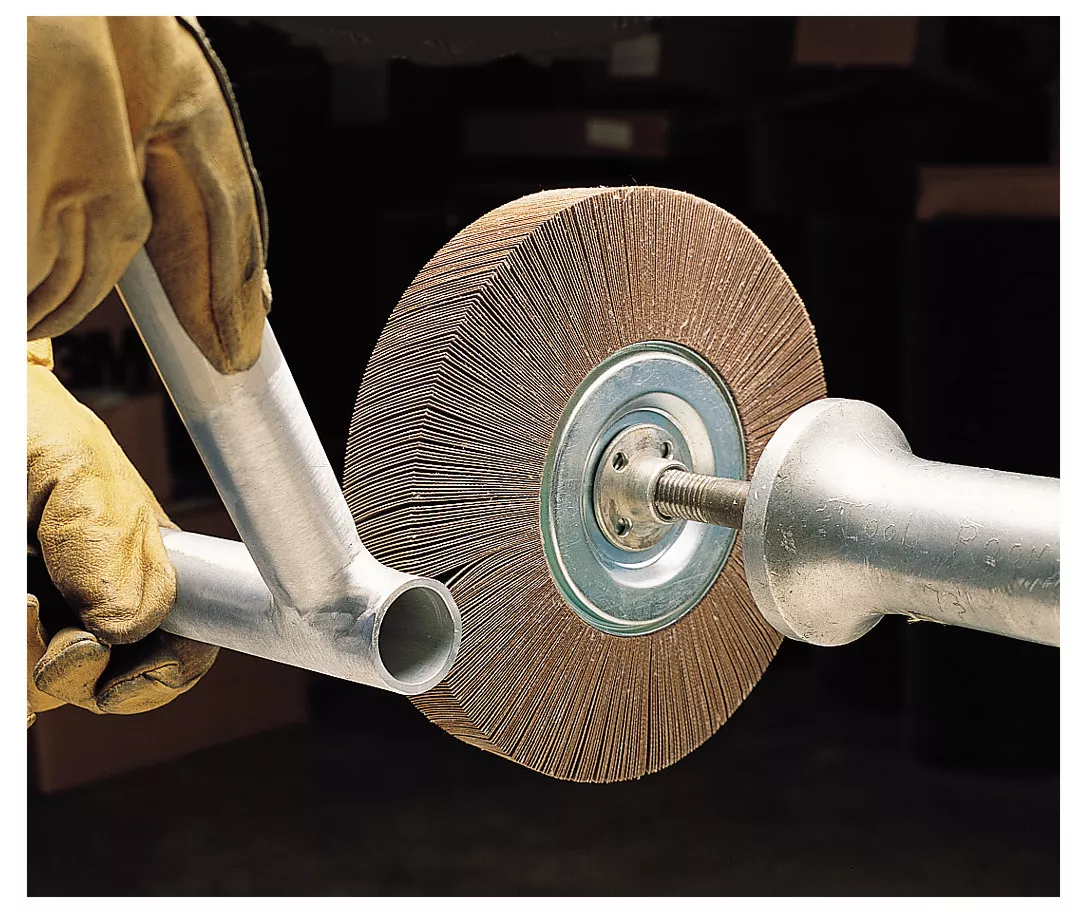

The 3M Flap Wheel 741A was designed for light grinding, blending, deburring, and polishing on a variety of metals. Ceramic abrasive covered flaps conform to the work piece and provide a smooth clean finish.

- Ceramic aluminum oxide blend offers excellent cut rate and life for better performance

- X-weight polyester/cotton backing withstands aggressive sanding and grinding

- Resin bonding resists thermal and chemical deterioration for extended wheel life

- Abrasive flap design provides a soft and smooth cut on rounded or irregular surfaces

- Flaps wear down to expose fresh abrasive mineral, assuring a fast and consistent cut

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 8.70826 lb |

|---|---|

| Length | 10.82677 in |

| Width | 6.77165 in |

| Height | 7.08661 in |

| Color | Maroon |

|---|

PRODUCT FAQ

-

What is the 3M™ Flap Wheel 741A made of?

The 3M™ Flap Wheel 741A is made of aluminum oxide abrasive.

-

Can this flap wheel be used on stainless steel surfaces?

Yes, the 3M™ Flap Wheel can be safely used on a range of metals, including stainless steel.

-

Is it easy to change out worn flap wheels for new ones?

Absolutely! All you need are tools like pliers and spanners to remove and replace worn wheels with new ones.

-

. How does the X-weight backing help in grinding processes?

. The X-weight paper backing is strong and provides added durability while also resisting tears during sharp corner sanding and edge chamfering applications.

-

. Does this product come in different sizes or only one size as described above?

A:The dimension for which you enquired that's (6 inches x 2inches x1 inch) comes with case quantity of five , however we do have other products similar to this but they come in different dimensions.

The 3M™ Flap Wheel 741A is a versatile tool that features a ceramic abrasive mix on each flap. This mix was created using a proprietary process that enhances the toughness and hardness of the grain. The mix consists of aluminum oxide blended with 3M ceramic grain, resulting in a harder and longer-lasting abrasive. Ceramic abrasives are engineered to cut fast and handle intense heat and stress applications, making them perfect for light to moderate stock removal. The ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability, making the 3M Flap Wheel 741A an excellent choice for moderate stock removal and surface preparation.

Tough ConstructionThe abrasive mix is attached to a flexible backing using a resin bond that resists thermal and chemical deterioration during high-speed sanding. The bond is very hard, allowing for faster cuts and a higher cut rate. Each flap uses an X-weight polyester/cotton backing, providing a tough and flexible surface that bends to fit any workpiece. As the wheel is used, the self-cutting flaps wear away to expose sharp, new abrasive material, ensuring that surfaces are sanded consistently throughout the life of the wheel.

Flap Wheel DesignCoated Abrasive flap wheels are the ideal choice for light grinding, blending, graining, and scale removal on a variety of metals. The abrasive flaps offer a long-lasting supply of fresh abrasives and a load-resistant design. The 3M Flap Wheel 741A is available in both flange mounted and spindle mounted constructions with general-purpose aluminum oxide or high-performing 3M ceramic aluminum oxide blend abrasive grain.