| SKU | 7000148192 |

|---|---|

| Legacy SKU | 60440273666 |

| UPC | 00051141556314 |

| Product Number | 967A |

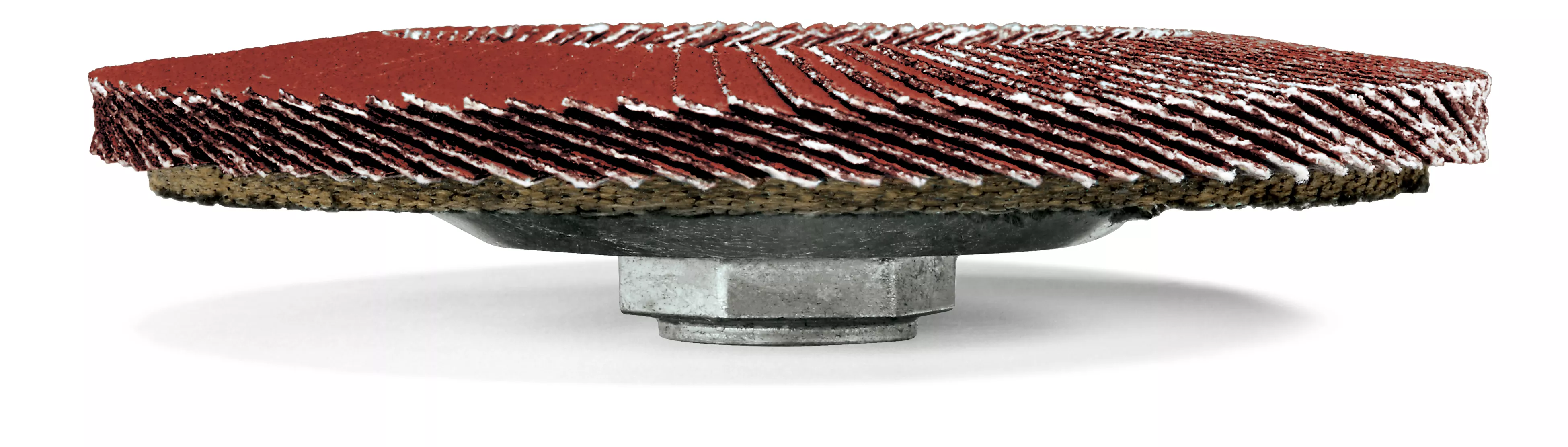

3M Cubitron II Flap Disc 967A is ideal for medium-pressure applications on flat and contoured surfaces, especially in light deburring or weld leveling to prep for paint in mild steel. Its also great for stainless steel fabrication where finish and gouge resistance are important. Powered by 3M Precision-Shaped Grain, this disc cuts fast and lasts long.

- Ideal 3M flap disc for medium-duty applications like weld removal and surface preparation

- Built with 3M Precision-Shaped Grain for an exceptionally fast cut, helping increase productivity

- Poly-cotton backing delivers controlled, even wear in medium unit pressure applications

- Individual flaps break down, exposing fresh mineral to deliver consistent cut rate for the life of the disc

- Easy to use, with less gouging than fiber discs and bonded wheels

- Offers a great balance of fast cut and long life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 7 in | 177.8 mm |

| Center Hole Diameter | 7/8 in | 22.225 mm |

Shipping Dimensions |

|

| Weight | 2.19999 lb |

|---|---|

| Length | 7.71654 in |

| Width | 7.71654 in |

| Height | 6.1811 in |

| Color | Maroon |

|---|---|

| Maximum Speed | 8,600 rpm |

PRODUCT FAQ

-

What is the 3M™ Cubitron™ II Flap Disc 967A used for?

The 3M™ Cubitron™ II Flap Disc 967A is typically used for heavy-duty edge and surface grinding applications on carbon steel, stainless steel, and other metals.

-

How does the disc compare to traditional abrasive discs?

The unique design of the 3M ™Cubitron™ II Flap Disc enables it to cut faster and last longer than traditional abrasive discs while producing an excellent finish.

-

What grit level is recommended for most metalworking applications with this flap disc?

The most common grit level recommended for this flap disc in metalworking application ranges from grade A60 (coarse) to grade A120 (fine), although lower or higher grades can also be used depending on specific needs.

-

. Is it easy to install this flap disc onto my grinder's arbor/ spindle?

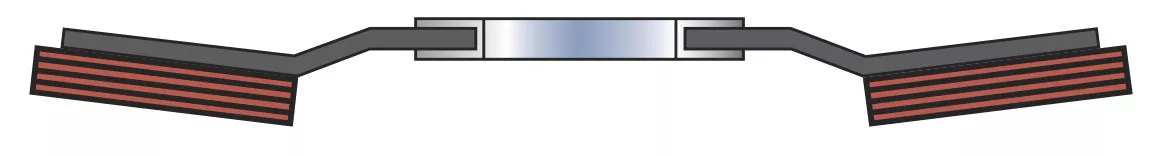

. Yes! This flap disk has a standard T29 angle-trimmed shape which requires no additional adapters or flanges; users are able to just press-fit them into compatible tools easily like any conventional fibre & depressed center type grinding wheels.

-

. what are some outstanding benefits when using these disks compared with similar products?

. Compared with similar products, our Cubitron ll safety product excels in several areas due its precision shaped grain technology that produces consistently high-quality results without overheating or premature shattering of the disk resulting in fewer worker changes required all throughout your projects leading towards maximized operation efficiencies especially beneficial in harsher work environments involving tougher metal surfaces during prolonged usage durations where overall cost effectiveness define reliable brands such as ours ultimately becoming industry leaders over time .

3M™ Cubitron™ II Flap Disc 967A – powered by 3M Precision-Shaped Grain and a poly-cotton backing – is well-suited for medium-duty applications including weld, scale and oxide removal, light deburring, surface preparation and blending. Along with the poly-cotton backing, this disc also features an incorporated grinding aid to help it run cool and cut efficiently on heat-sensitive metals. This all adds up to a disc that strikes a balance of fast cut and long life.

Flap Disc DesignFlap discs are the ideal choice for a wide range of applications on a variety of metals. The abrasive flaps offer a long-lasting supply of fresh abrasives in a load-resistant design. Designed for use with a right-angle grinder, flap discs allow you to breeze through a wide range of applications with less chance of gouging – even for less-experienced grinders.

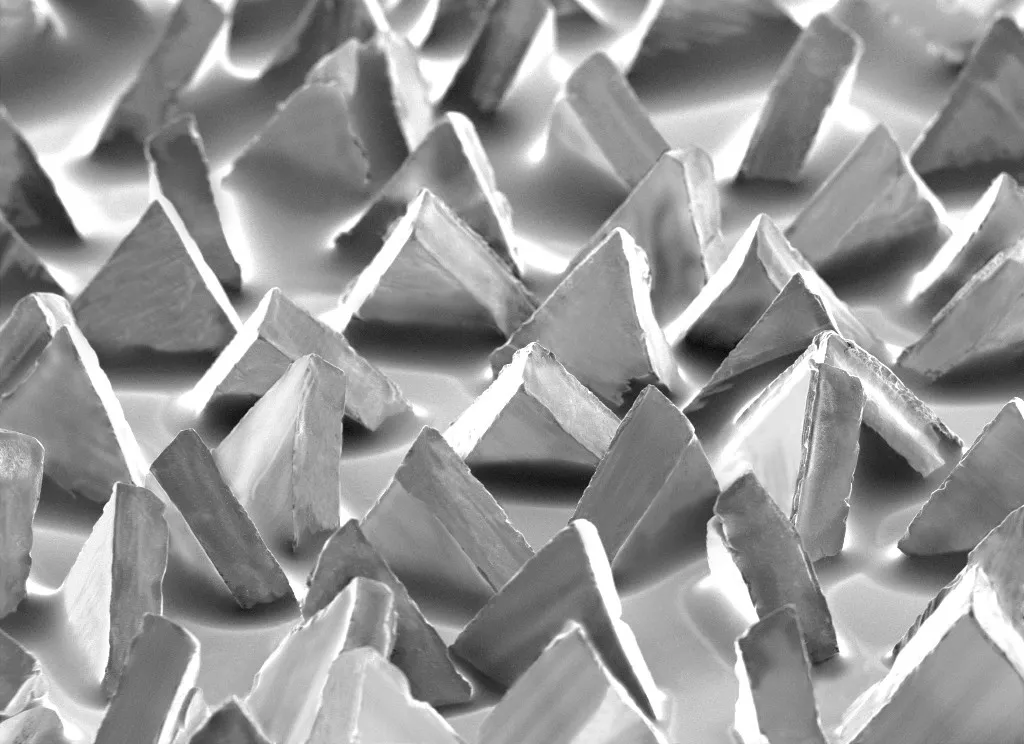

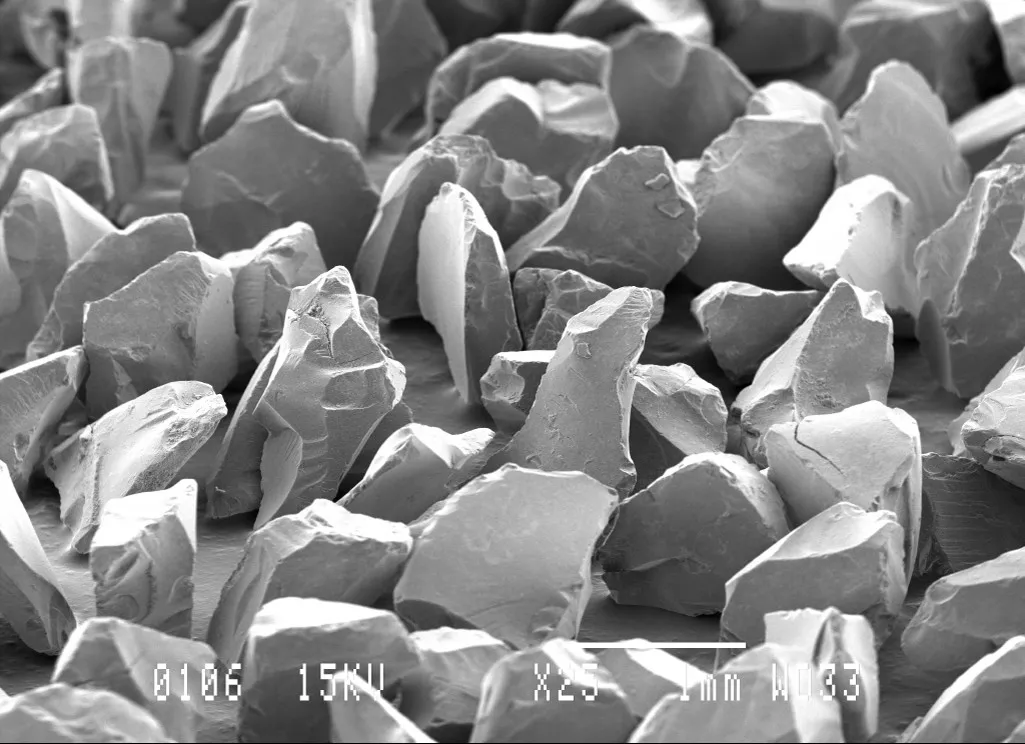

Powered by 3M Precision-Shaped Grain3M™ Cubitron™ II Flap Disc 967A features proprietary 3M Precision-Shaped – a grain design that continually fractures into sharp points that slice cleanly through metal, unlike traditional abrasives which tend to plow through the substrate. The grains fracture evenly and continuously expose new sharp edges to keep the disc cutting efficiently. The result is that 3M™ Cubitron™ II products out-cut and outlast conventional ceramic industrial abrasives.

Applications- Weld removal

- Light deburring

- Scale removal

- Oxide removal

- Surface prep

- Blending