| SKU | 7000046256 |

|---|---|

| Legacy SKU | 61500293727 |

| UPC | 00048011604718 |

| Product Number | 337DC |

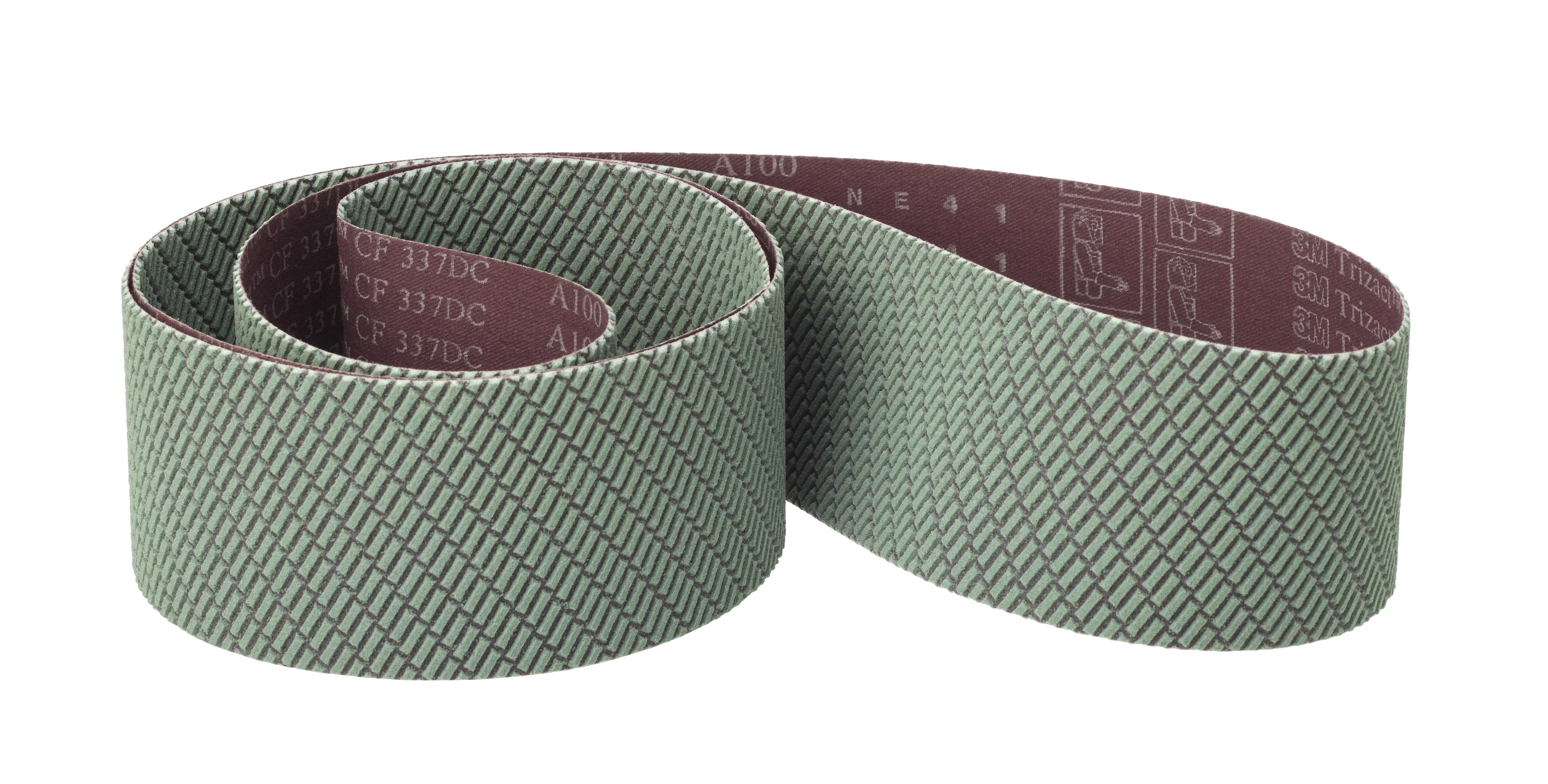

3M Trizact Hookit Cloth Disc 337DC provides fast scratch removal on automotive metal components and leaves a superior finish. Premium aluminum oxide macroreplicated grain on an X-weight backing combine to contribute to long product life and consistent performance for greater productivity.

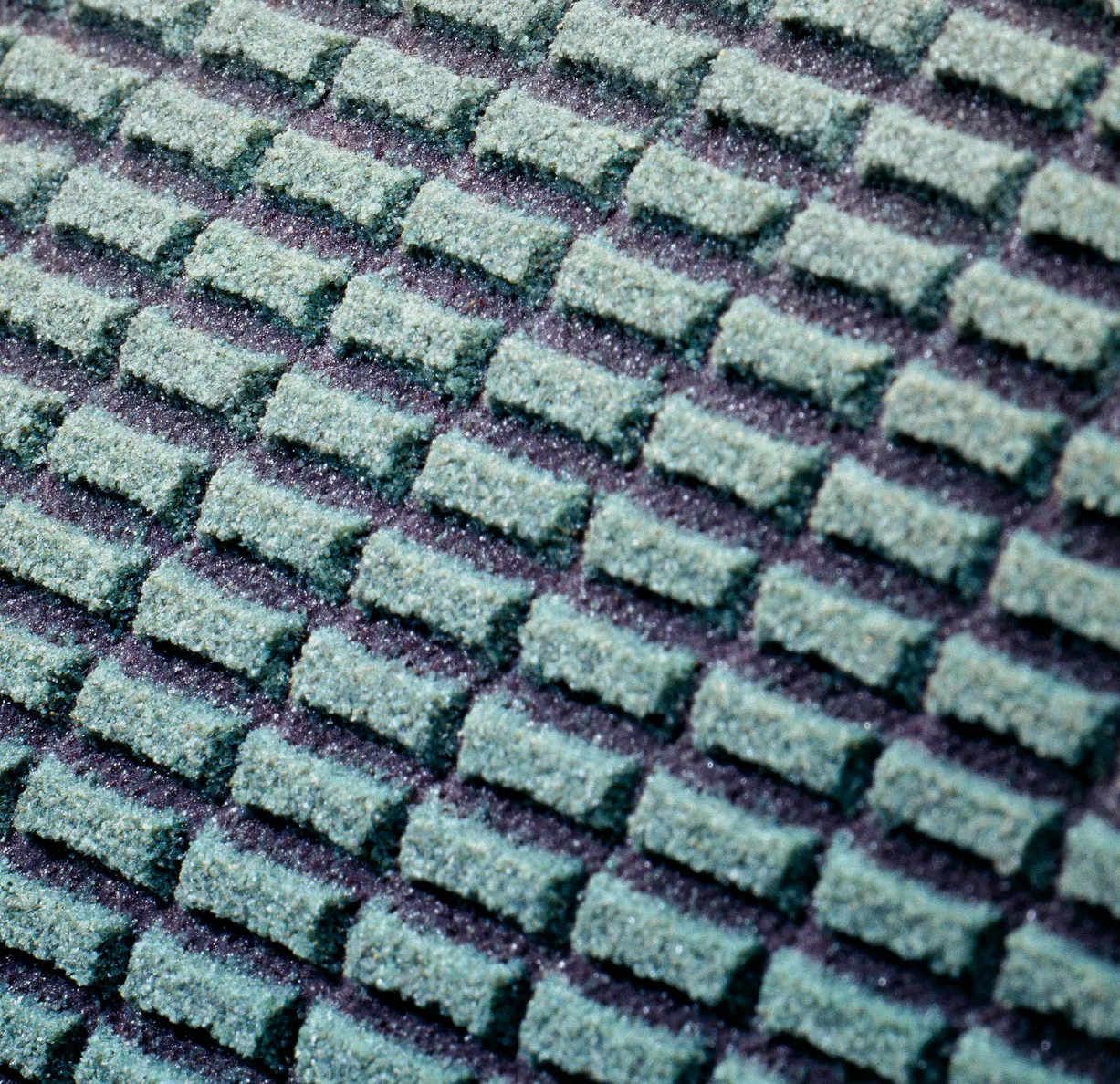

- Microreplicated "bricks and channels" abrasive structure reduces loading

- Provides fast scratch removal on automotive white metal and other applications

- Controlled abrasive breakdown delivers consistent, predictable finish

- Generates minimal heat, suitable for multiple substrates

- 3M™ Hookit attachment backing makes swapping discs quick and easy

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 3.50006 lb |

|---|---|

| Length | 6.49606 in |

| Width | 6.49606 in |

| Height | 5.31496 in |

| Maximum Speed | 12,000 rpm |

|---|

PRODUCT FAQ

-

What is the main feature of 3M™ Trizact™ Hookit™ Cloth Disc 337DC, 6 in x NH, A160 X-weight?

The main feature of this product is its long-lasting abrasive performance which helps to reduce rework and improve productivity.

-

What material can be used with this disc?

This cloth disc can be perfectly suited for working on a variety of metals like carbon steel, stainless steel and other exotic alloys.

-

Is it easy to use?

Yes! Its precisely shaped pyramids are distributed uniformly across the face plate making it convenient to handle during application.

-

How many discs come in one case?

One case includes fifty(50) pieces each measuring six inches by non-holed(NH).

-

Will this product work well under wet or dry conditions?

. Trizact abrasives technology combined with Hookit attachment method provides consistent finishes even if moisture presents on surfaces.Thus,it works efficiently both in wet or dry conditions.

3M™ Trizact™ Hookit™ Cloth Disc 337DC is a product designed for automotive white metal repair. It is perfect for blending and finishing minor defects and removing scratch marks left behind by metal files or rotary tools. This product provides a fast scratch removal capability and a superior finish, leaving the surface ready for e-coat application.

This cloth disc is available in 5-inch diameters and grades of A300, A160, A100, A65, A45, A30, as well as make-to-order sizes.

"Bricks and Channels" Abrasive StructureThe geometrical "bricks-and-channels" abrasive structure of 337DC products is made possible by microreplication technology. These unique abrasive bricks contain up to four times as much mineral as conventional abrasives. As the mineral breaks down, fresh mineral is exposed.

The microreplicated pattern of 3M™ Trizact™ Hookit™ Cloth Disc 337DC generates minimal heat. The open spaces between the abrasive bricks channels heat away and removes swarf. This means you can use these discs on substrates like galvanized panels, aluminum hoods, and other applications where loading may be an issue.

Get a Grip With Hookit Attachment3M's Hookit™ hook-and-loop attachment makes disc attachment, removal, and re-attachment clean and easy, and facilitates re-use of the disc for the extent of the abrasive life.

It couldn't be simpler to attach a disc and it stays firmly seated. In addition, they are more flexible and they resist contamination by dust, dirt, and debris, unlike pressure sensitive adhesive backings.

Recommended Applications- Hand file scratch refinement

- Rotary tool scratch refinement

- Blending and finishing of minor defects

- Effective on galvanized and aluminum parts

3M's microreplication technology allows them to engineer the geometry of abrasive grain, to create and reproduce perfectly calibrated three-dimensional composite structures —pyramids, hemispheres, cubes — and distribute them precisely and uniformly across an abrasive backing. Each is identical in height and orientation, eliminating the danger of uneven edges or deep scratches. As the abrasive wears, a continuous supply of fresh, sharp abrasive mineral is exposed, sustaining consistent cutting performance and profile.

The science that makes 3M's structured abrasives work better and wear more evenly, provide pristine finishes for delicate components is also the science that makes road signs, electronic displays, and exterior building illumination capture and reflect light more brilliantly.