| SKU | 7010365366 |

|---|---|

| Legacy SKU | 61500192911 |

| UPC | 00048011337814 |

| Product Number | 337DC |

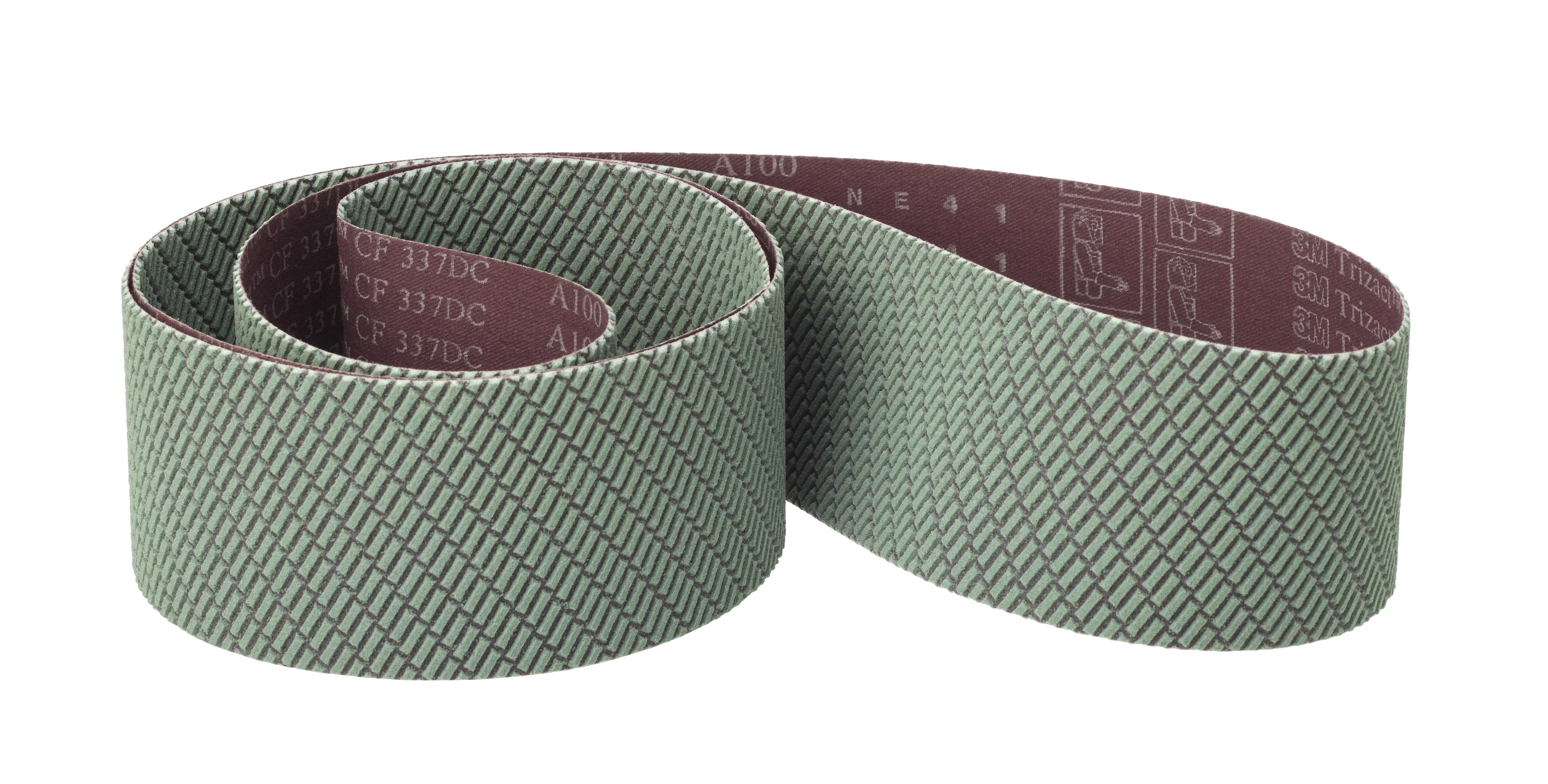

The 3M Trizact Cloth Belt 337DC delivers consistently in intermediate to final finish, medium pressure applications. Designed with aluminum oxide and a grinding aid on a durable X- weight cloth backing, this belt is available in widths from 1/2 to 24 inches and grades from A300 to A30.

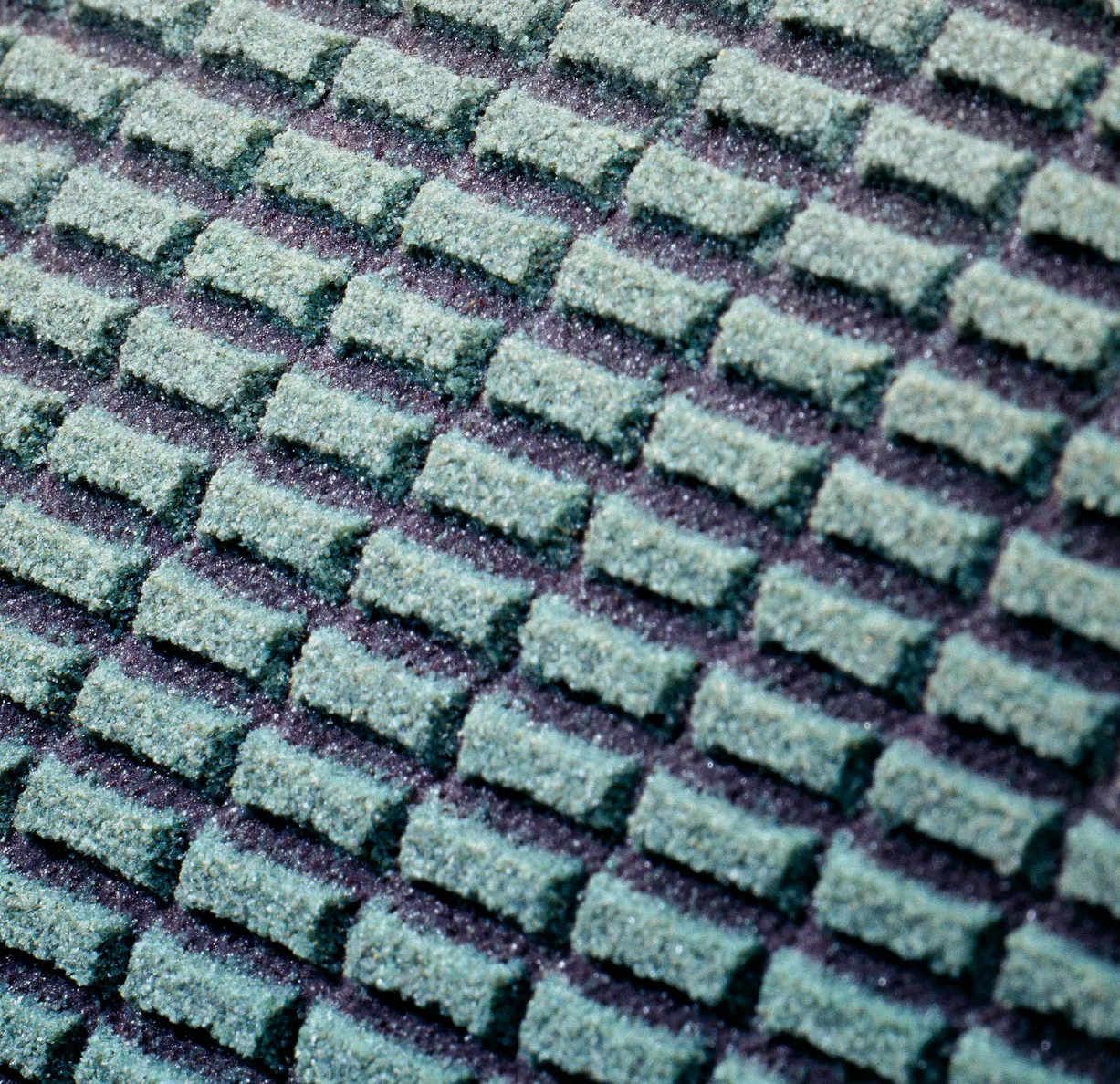

- Macroreplicated abrasive "bricks" contain multiple layers of abrasive mineral, "channels" keep remove swarf and keep work surfaces cleaner

- Controlled mineral breakdown delivers more consistent, predictable finishes over the life of the belt

- Durable cloth belt is frequently able to grind and finish in one operation

- Grinding aid reduces friction and keeps workpiece cool for dry grinding applications

- Extra-long belt life reduces abrasive cost and inventory

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 10.08 lb |

|---|---|

| Length | 12 in |

| Width | 12 in |

| Height | 9.2 in |

PRODUCT FAQ

-

What is the length and width of 3M™ Trizact™ Cloth Belt 337DC, A100 X-weight?

The length is 72 inches and the width is 1-1/2 inches.

-

What type of attachment does this belt use?

This belt uses Film-lok technology for secure attachment to your machine.

-

Does this cloth belt have any flexibility or give?

No, it has no flex or give which ensures uniform abrasive scratch patterns.

-

. How many belts do I get in a single case order?

. You will receive a total of 50 belts per case order.

-

. Is there anything special about the grit used on this abrasive cloth belt?

. Yes! This Cloth Belt features an A100 grit that provides fine edges, outstanding consistency, and impressive durability ensuring longer-lasting abrasion performances.

The 3M™ Trizact™ Cloth Belt 337DC is a durable and high-performing abrasive belt that owes its consistent sustained cut rate to its uniquely engineered "bricks and channels" macroreplicated abrasive structure. The uniform abrasive "bricks" keep fresh cutting mineral constantly at the working surface, while the "channels" sweep debris away to discourage loading and keep the substrate clean.

The "bricks" consist of layers of mineral and grinding aid, up to 4 times as much as conventional aluminum oxide belts of the same grade. These dense layers of abrasive mineral lead to extra-long life and extremely consistent performance. The grinding aid protects heat-sensitive alloys from damage and reduces rework. Trizact belts start sharp and stay sharp, delivering a consistent cut that can often consolidate or eliminate process steps. In many cases, Trizact™ 337DC has the capacity to grind and finish in one step.

Microreplication: Engineering Surface GeometryBuilding upon the principles of microreplication, 3M scientists developed larger, more diverse abrasive structures —cubes, spheres, ridges — identical in shape and optimized for a variety of applications. Microreplication allows 3M to design abrasives with varying shapes and formulations, to control the level of breakdown, cut, finish, and life.

These abrasive structures are arrayed precisely and uniformly across a film or cloth backing in a pattern calculated to deliver sustained cut rate and eliminate belt-to-belt variation.

Made to Tackle Difficult MetalsTrizact was developed especially for finishing more difficult processing materials like titanium, cobalt, stainless steel, as well as all exotic alloys in the aerospace, aviation, and medical industries. It is also effective for finishing applications on carbon steel, copper, bronze, aluminum, composite materials, and synthetics.

Recommended ApplicationsUse for dry intermediate finishing, blending, scratch refinement, or final dimensioning on robotic, semi-automated, automated, off-hand equipment, and portable file belt tools. Use Trizact™ Cloth 337DC belts with:

- Medium hardness contact wheels (50-70 Shore A)

- Rubber contact wheels

- Smooth face to gentle serrated contact wheel

To prepare drawn carbon steel truck exhausts from rough to pre-plate finishes in as few steps as possible, we used a grade sequence of A100, A65, A30. Trizact™ 337DC outlasted a competitor by 2:1. For blending, final dimensioning, and finishing of turbine engine components, the grade A45 Trizact 337DC belt outlasted a competitor's belt by 4:1 times and produced a finer finish.

Creating More Perfect SurfacesMicroreplication is only one of 3M's platform of core technologies. Its perfectly calibrated arrays are designed to give materials new physical, chemical, or optical properties. The science that makes 3M's structured abrasives wear more evenly, last longer, and provide more pristine finishes on delicate components like medical implants is also the science that makes traffic signs brighter, and exterior building illumination capture and reflect light more brilliantly.