| SKU | 7010365339 |

|---|---|

| Legacy SKU | 61500190451 |

| UPC | 00048011331652 |

| Product Number | 337DC |

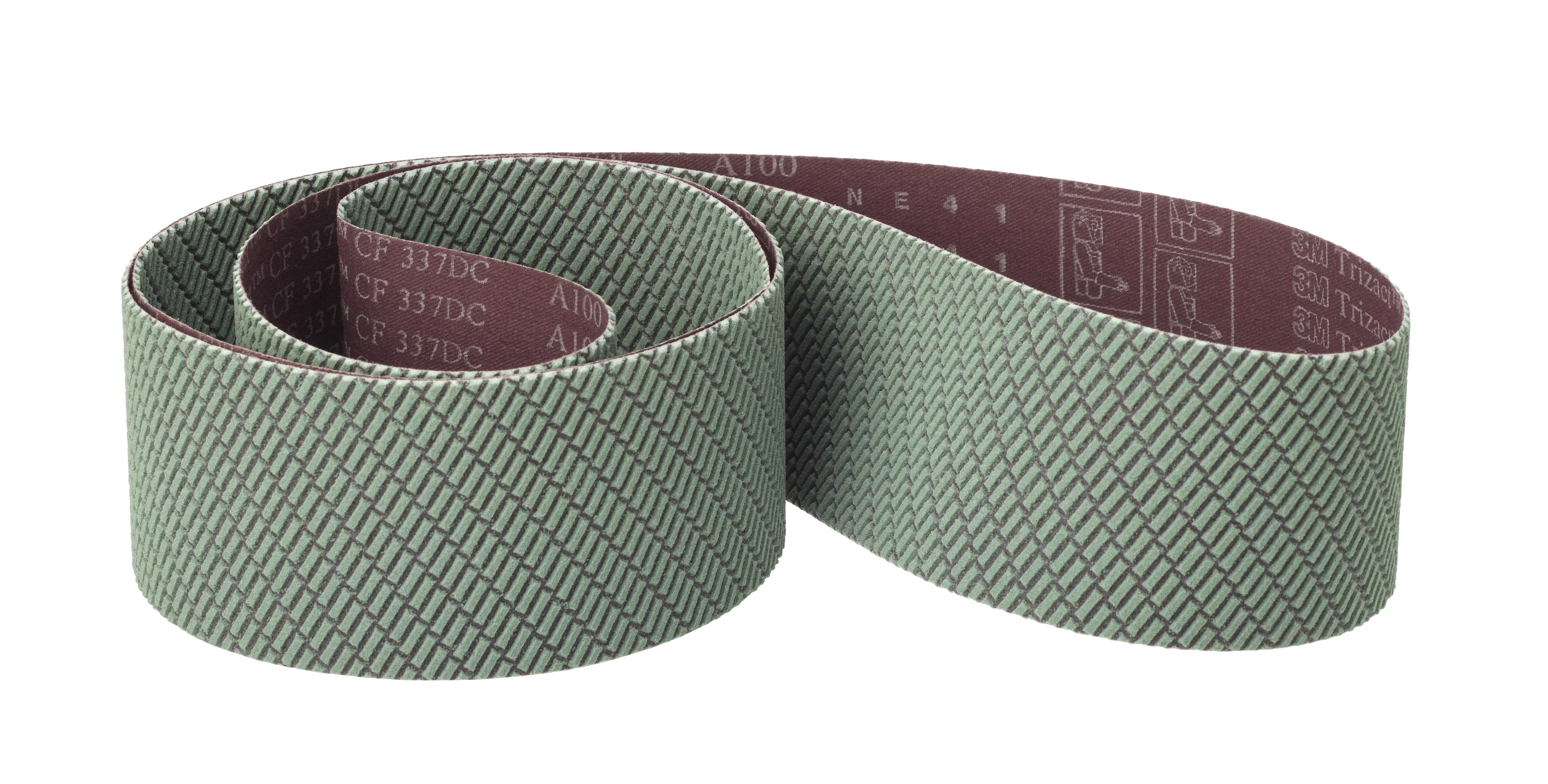

The 3M Trizact Cloth Belt 337DC delivers consistently in intermediate to final finish, medium pressure applications. Designed with aluminum oxide and a grinding aid on a durable X- weight cloth backing, this belt is available in widths from 1/2 to 24 inches and grades from A300 to A30.

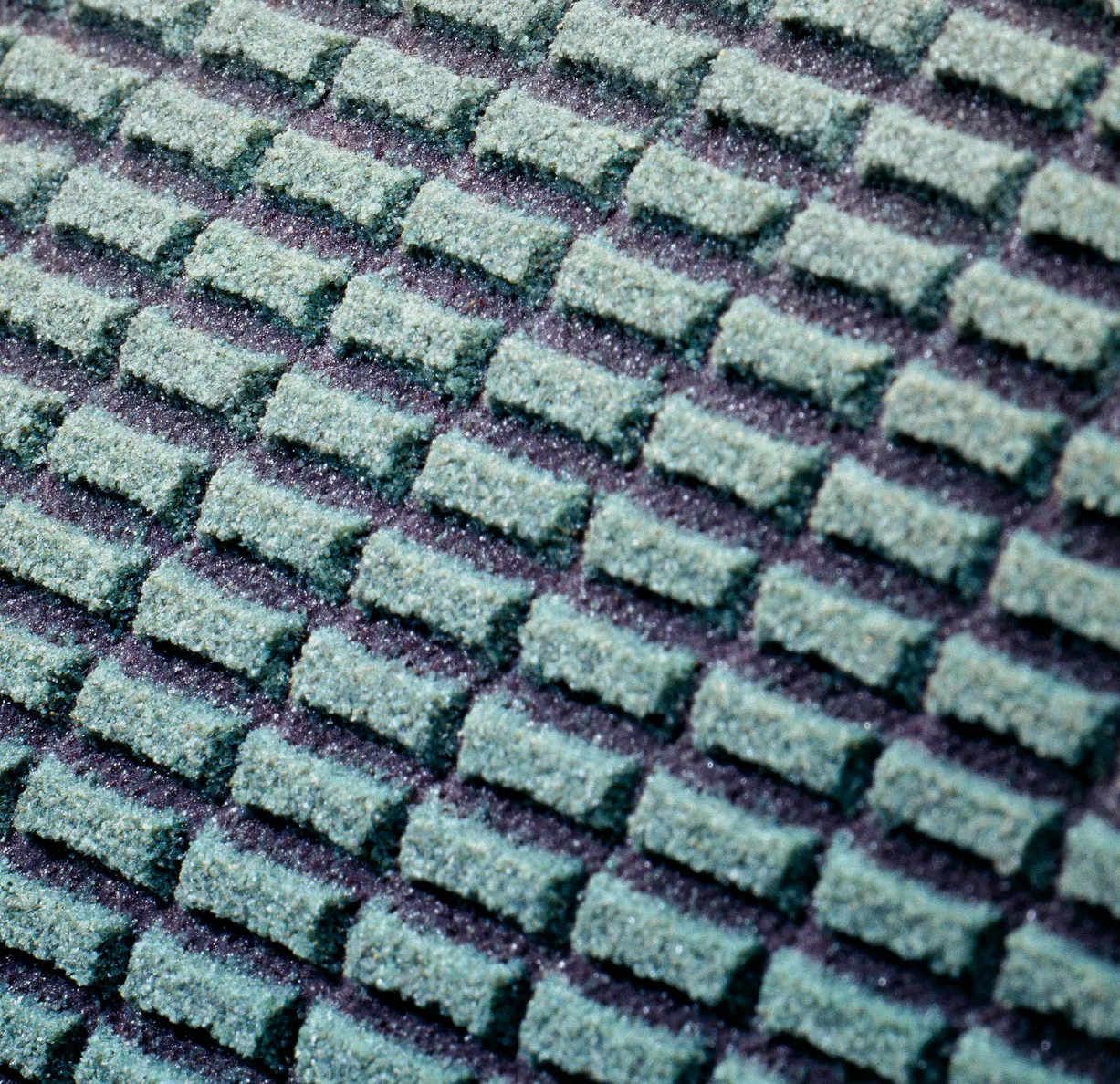

- Macroreplicated abrasive "bricks" contain multiple layers of abrasive mineral, "channels" keep remove swarf and keep work surfaces cleaner

- Controlled mineral breakdown delivers more consistent, predictable finishes over the life of the belt

- Durable cloth belt is frequently able to grind and finish in one operation

- Grinding aid reduces friction and keeps workpiece cool for dry grinding applications

- Extra-long belt life reduces abrasive cost and inventory

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 3.458 lb |

|---|---|

| Length | 12 in |

| Width | 12 in |

| Height | 4.81299 in |

PRODUCT FAQ

-

bsolutely, I can help with that!

What is the grit size of the 3M™ Trizact™ Cloth Belt 337DC, A65 X-weight?

-

The belt has a grit size of A65, providing effective material removal and consistent finish.

How many belts come in a case of the 3M™ Trizact™ Cloth Belt 337DC?

-

There are 5 belts included in each case, making it convenient for your needs.

Does the belt have Film-lok backing on it?

-

Yes, the belt features Film-lok backing which ensures secure attachment during sanding applications.

The 3M Trizact Cloth Belt 337DC is a highly durable and reliable abrasive belt that offers a consistent sustained cut rate. Its exceptional performance is attributed to its uniquely engineered "bricks and channels" macroreplicated abrasive structure. This structure consists of uniform abrasive "bricks" that ensure fresh cutting mineral is always present at the working surface, while "channels" effectively sweep away debris to prevent loading and keep the substrate clean.

Unlike conventional aluminum oxide belts, the "bricks" of the Trizact Cloth Belt 337DC contain layers of mineral and grinding aid, up to four times more than standard belts of the same grade. This dense layering of abrasive mineral results in an extended lifespan and remarkably consistent performance. Additionally, the grinding aid incorporated in the belt protects heat-sensitive alloys from damage, reducing the need for rework. Trizact belts maintain their sharpness throughout their lifespan, delivering a consistent cut that often eliminates the need for multiple process steps. In fact, Trizact 337DC has the capability to grind and finish in a single step in many cases.

Microreplication: Engineering Surface GeometryBuilding upon the principles of microreplication, 3M scientists have developed larger and more diverse abrasive structures, including cubes, spheres, and ridges. These structures are precisely and uniformly arranged across a film or cloth backing, forming a pattern that is specifically designed to deliver a sustained cut rate and eliminate any variation between belts.

Microreplication allows 3M to create abrasives with varying shapes and formulations, enabling precise control over factors such as breakdown, cut, finish, and lifespan. This technology plays a crucial role in designing abrasives that can tackle the finishing of difficult processing materials, such as titanium, cobalt, stainless steel, and exotic alloys commonly found in the aerospace, aviation, and medical industries. Trizact belts are also effective for finishing applications on carbon steel, copper, bronze, aluminum, composite materials, and synthetics.

Recommended ApplicationsThe Trizact Cloth 337DC belts are ideal for dry intermediate finishing, blending, scratch refinement, or final dimensioning. They can be used with robotic, semi-automated, automated, off-hand equipment, and portable file belt tools. For optimal performance, it is recommended to use Trizact Cloth 337DC belts with medium hardness contact wheels (50-70 Shore A), rubber contact wheels, or smooth face to gentle serrated contact wheels.

In a real-world application, we used a grade sequence of A100, A65, and A30 Trizact belts to prepare drawn carbon steel truck exhausts from rough to pre-plate finishes in the fewest steps possible. The Trizact 337DC belt outlasted a competitor's belt by a ratio of 2:1. Similarly, for blending, final dimensioning, and finishing of turbine engine components, the grade A45 Trizact 337DC belt outlasted a competitor's belt by a ratio of 4:1 and produced a finer finish.

Creating More Perfect SurfacesMicroreplication is just one of the core technologies employed by 3M. This technology allows for the precise calibration of arrays, giving materials new physical, chemical, or optical properties. The same science that makes 3M's structured abrasives wear more evenly, last longer, and provide pristine finishes on delicate components like medical implants is also responsible for making traffic signs brighter and enhancing the capture and reflection of light in exterior building illumination.