| SKU | 7000028889 |

|---|---|

| Legacy SKU | 70006122181 |

| UPC | 00021200856174 |

| Catalog Number | 470 |

| Product Number | 470 |

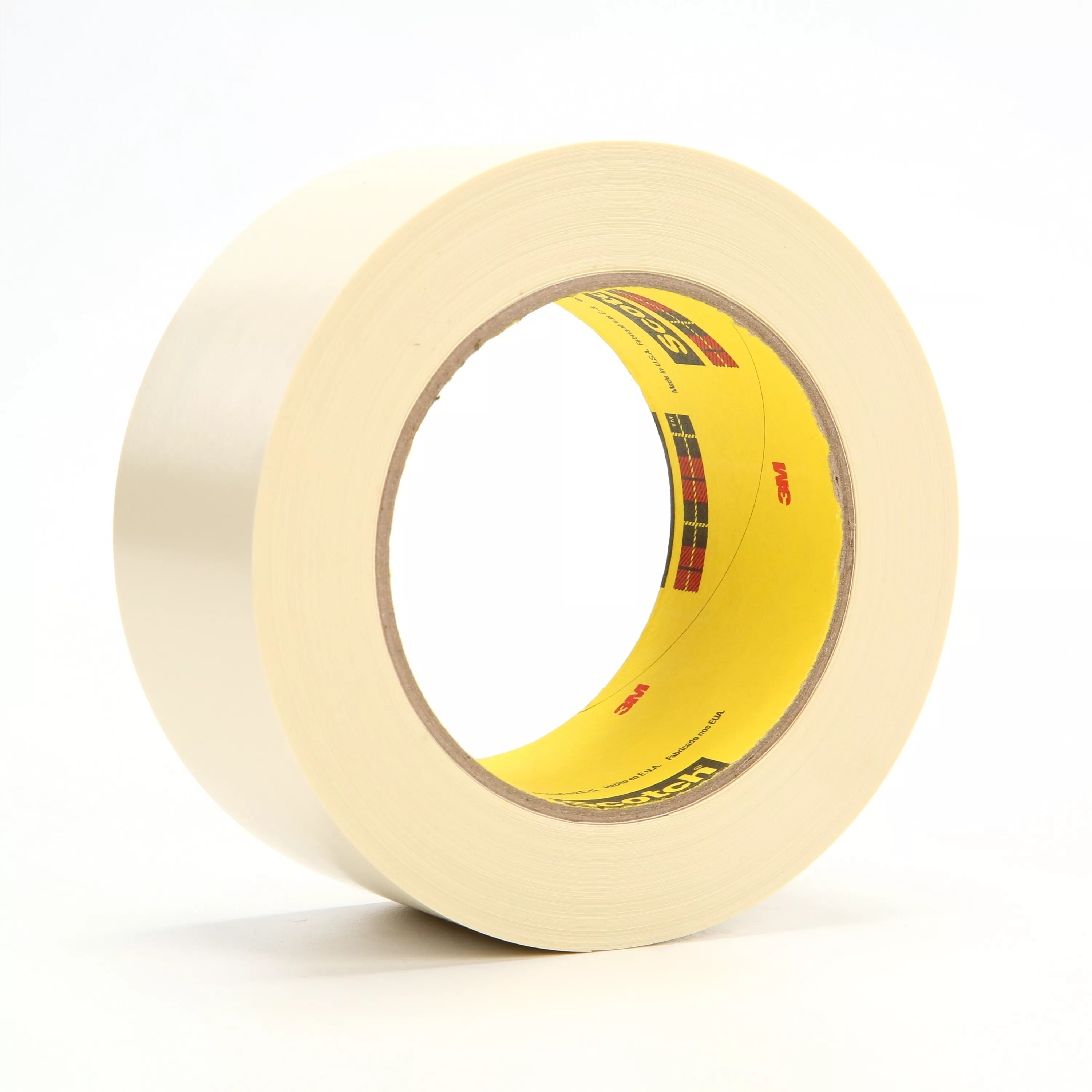

For tape applications requiring resistance to most chemicals used in electroplating and anodizing processes, use our 3M Electroplating Tape 470. This tan, conformable tape features an abrasion resistant backing ideal for use with plating chemicals, anodizing chemicals, milling, etching and peening operations.

- Excellent resistance to most chemicals used in typical electroplating and anodizing operations

- Resists most common solvents and works at temperatures up to 121°C/250°F

- Abrasion, moisture and wear resistant to withstand rugged working conditions

- Conformable backing is ideal for use on curved and irregular surfaces

- Rubber adhesive provides excellent holding strength on many surfaces

- This version of 470 has no liner

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 7.1 mil | 0.18 mm |

Shipping Dimensions |

|

| Weight | 23.02067 lb |

|---|---|

| Length | 10.7874 in |

| Width | 10.7874 in |

| Height | 12.99213 in |

| Color | Tan |

|---|

PRODUCT FAQ

-

How does 3M™ Electroplating Tape 470 differ from regular tape?

Great question! 3M™ Electroplating Tape 470 is specially designed for electroplating and anodizing processes. It has excellent resistance to electrolytes, helping to prevent edge burn through and the need for costly rework.

-

What are the dimensions of each roll of 3M™ Electroplating Tape 470?

Each roll of our 3M™ Electroplating Tape 470 measures at (50.8 mm x 32.9 m) with a thickness of (7.1 mil). And a case contains up to twenty-four rolls so that you can save more!

-

Can I use this tape in extreme temperatures?

Absolutely! Our patented backing technology ensures that this tape offers high adhesion even in adverse conditions like heat or chemical exposure, providing reliable performance all year-round without losing integrity due to temperature fluctuations across its range (-34°C –121 °C).

3M™ Electroplating Tape 470 is designed to withstand the harsh and challenging conditions associated with electroplating and anodizing processes. Its flexible vinyl backing conforms to irregular or curved surfaces. It is resistant to most common solvents and has excellent resistance to chemicals used in electroplating and anodizing. This tape can operate at temperatures of up to 170°F/76°C. After use, the tape can be removed cleanly from most surfaces. The backing can also accept marker ink and is printable using a thermal transfer process, making customization relatively easy when needed.

Recommended Applications- Masking during electroplating operations, including both flat strip and overlapping masks

- Masking during anodizing operations

- Wrapping, patching, coated racks and masking irregular surfaces

- Labeling

- Milling and etching

- Peening operations

- Sealing containers from water intrusion

In the 3M Industrial Adhesives and Tapes Division, they apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. Ultimately, our technologies help customers like you deliver competitive products to the market faster and more efficiently.