| SKU | 7100259914 |

|---|---|

| Legacy SKU | 61500335395 |

| UPC | 00638060890189 |

| Product Number | SC-BL |

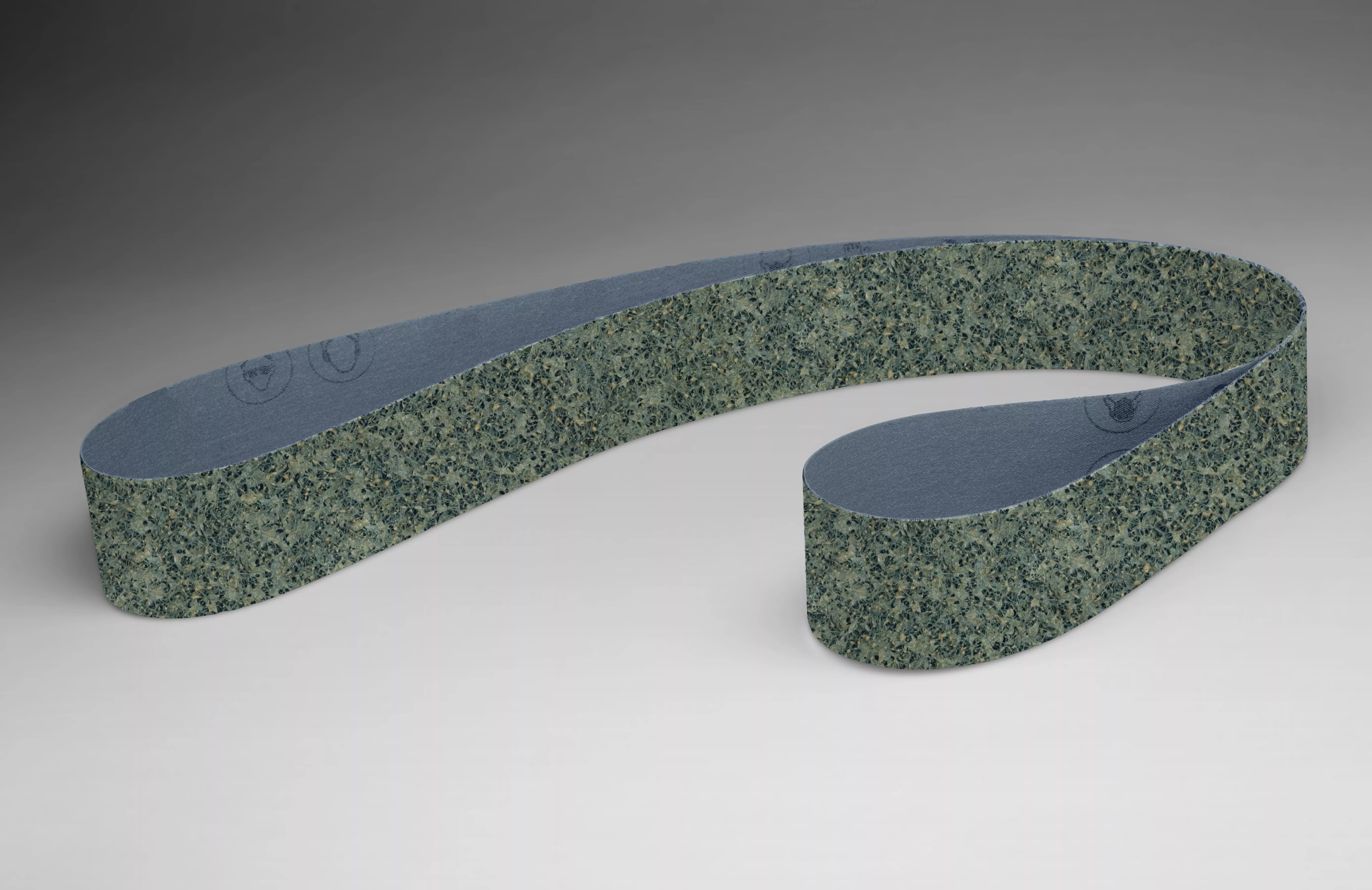

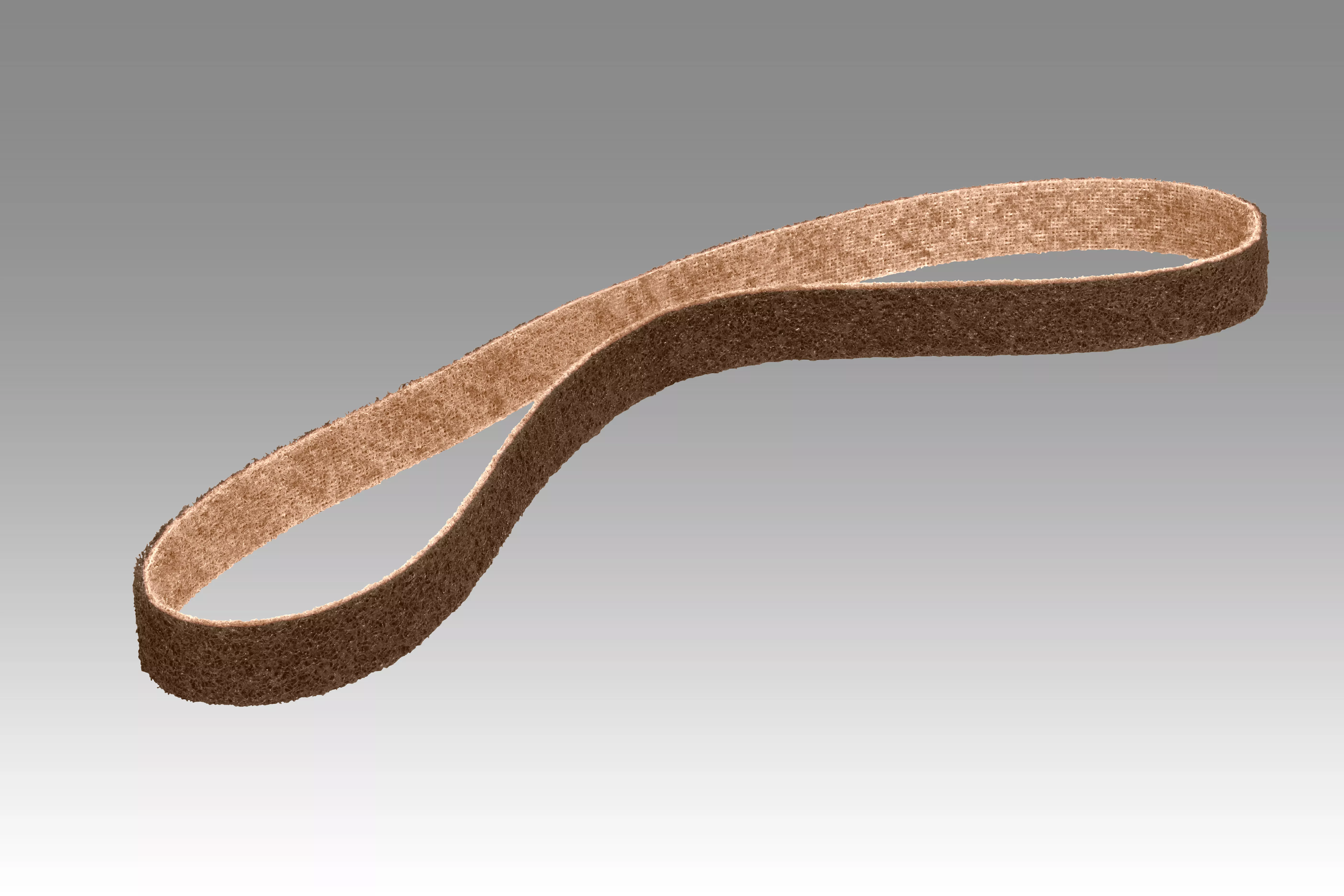

Among Scotch-Brite Surface Conditioning Belts, the Scotch-Brite Surface Conditioning Low Stretch Belt falls right in the middle in terms of its durability and flexibility. Its moderate strength makes it versatile and useful in many sequences cutting aggressively without marring the substrate.

- Durable cloth / polyester scrim backing is ideal for low-stretch applications

- May be used on a variety of substrates, from stainless steel to brass

- Available in a variety of minerals, grades and belt types, so operators can choose the right combination for their application

- Springy non-woven nylon fibers finish while maintaining the geometry of the piece

- Open web is load resistant, prolonging abrasive service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 0.896 lb |

|---|---|

| Length | 8.6 in |

| Width | 8.5 in |

| Height | 6.7 in |

PRODUCT FAQ

-

Can you tell me more about the Scotch-Brite™ Surface Conditioning Low Stretch Belt, SC-BL?

Certainly! The Scotch-Brite™ SC-BL belt is a versatile surface conditioning product designed for various applications.

-

What are the dimensions of this particular belt?

This specific belt is half an inch wide and 18 inches long, making it ideal for smaller surfaces or projects.

-

How many belts come in each case?

There are a total of 20 belts included in each case, providing ample supply for your needs.

-

What does "Scuffed Splice" mean in relation to this product?

The "Scuffed Splice" feature indicates that the splice joint on these belts has been scuffed, ensuring smooth operation and minimal interference during use.

-

Is this belt suitable for medium-duty tasks?

Yes, the Scotch-Brite™ SC-BL belt with A Medium grit is perfect for medium-duty surface conditioning jobs.

The Scotch-Brite Surface Conditioning Low Stretch Belt is specifically designed to handle cleaning, finishing, and light deburring tasks. Its unique combination of durability and flexibility makes it an excellent choice for various applications. While it performs exceptionally well on steel and stainless steel, carbon, titanium, and nickel alloys, it can also be used on other metals such as aluminum, copper, brass, and soft, non-ferrous metals. With a wide range of variations available, operators can easily find the perfect belt for their specific project.

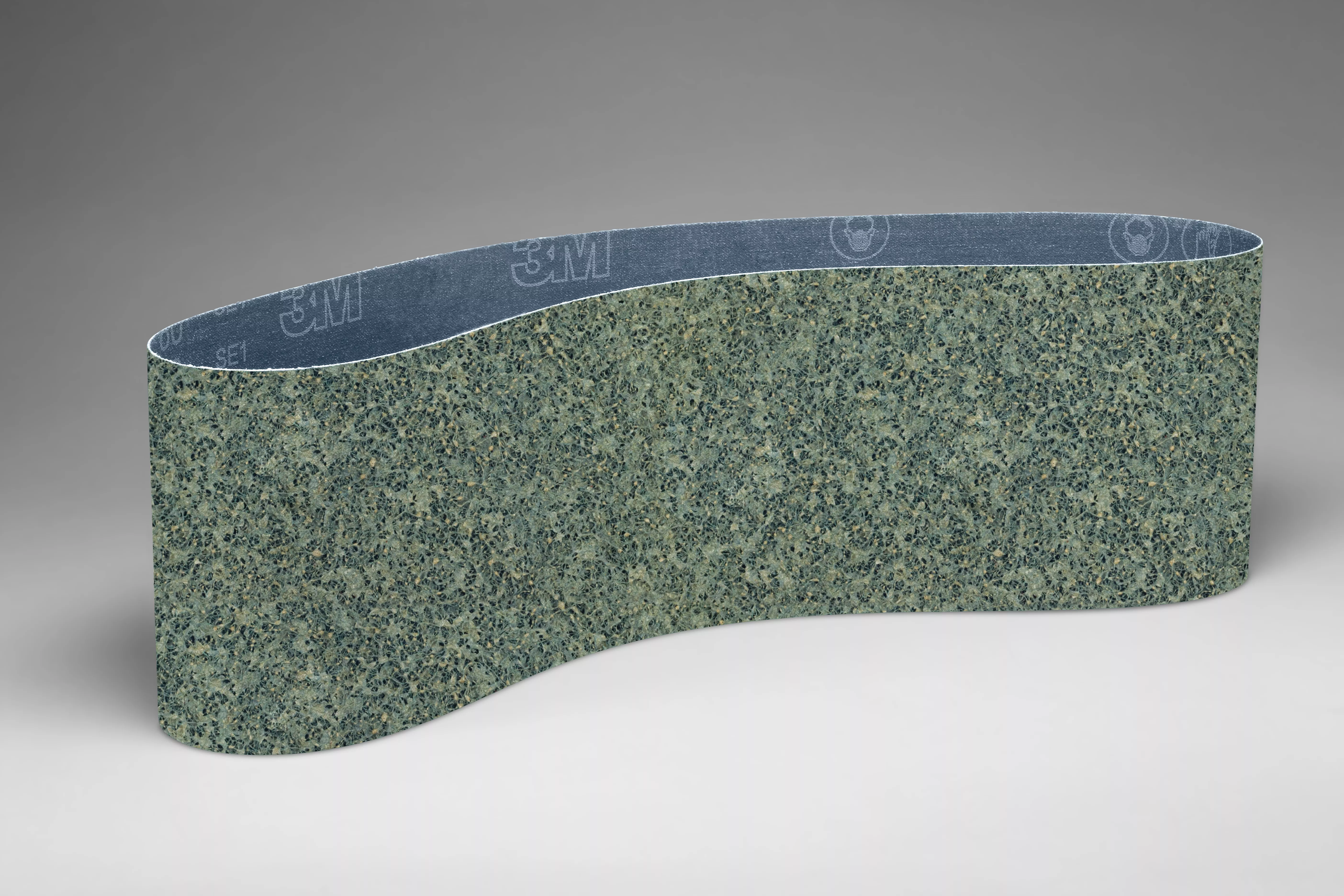

Minerals, Grades, and Belt TypesThe Scotch-Brite Surface Conditioning Low Stretch Belt is engineered using high-quality aluminum oxide and silicon carbide minerals. These minerals are available in different combinations, including aluminum oxide medium (A MED), aluminum oxide very fine (A VFN), aluminum oxide coarse (A CRS), silicon carbide medium (S MED), silicon carbide super fine (S SFN), and silicon carbide very fine (S VFN).

When it comes to choosing between aluminum oxide and silicon carbide, it's important to consider the desired outcome. Aluminum oxide is known for its longer-lasting durability and softer cutting action, making it ideal for projects where a soft scratch is desired. On the other hand, silicon carbide offers a coarser and more aggressive cut, making it suitable for projects that require a rougher finish.

Depending on the desired finish, operators can select from a range of grades. Fine grades are perfect for achieving finer finishes, while medium or coarse grades are better suited for coarser finishes. The Scotch-Brite Surface Conditioning Low Stretch Belt is specifically designed for "low stretch" applications, where a standard scrim belt may stretch on the machine or when less conformability is desired. This belt is resistant to wear and sharp edges, making it a valuable tool in various industries, including transportation and metal fabrication.

Operators can choose from different types of belts, including file, narrow, portable, pump sleeve, and wide & flat finishing belts. When selecting a belt, it's essential to consider factors such as the tools being used, the surface area, contours, and dimensions of the workpiece. Narrow belts are commonly used in benchstand and backstand applications, while pump sleeves are specifically designed to fit around expander wheels and are used for finishing large equipment that cannot be easily moved.

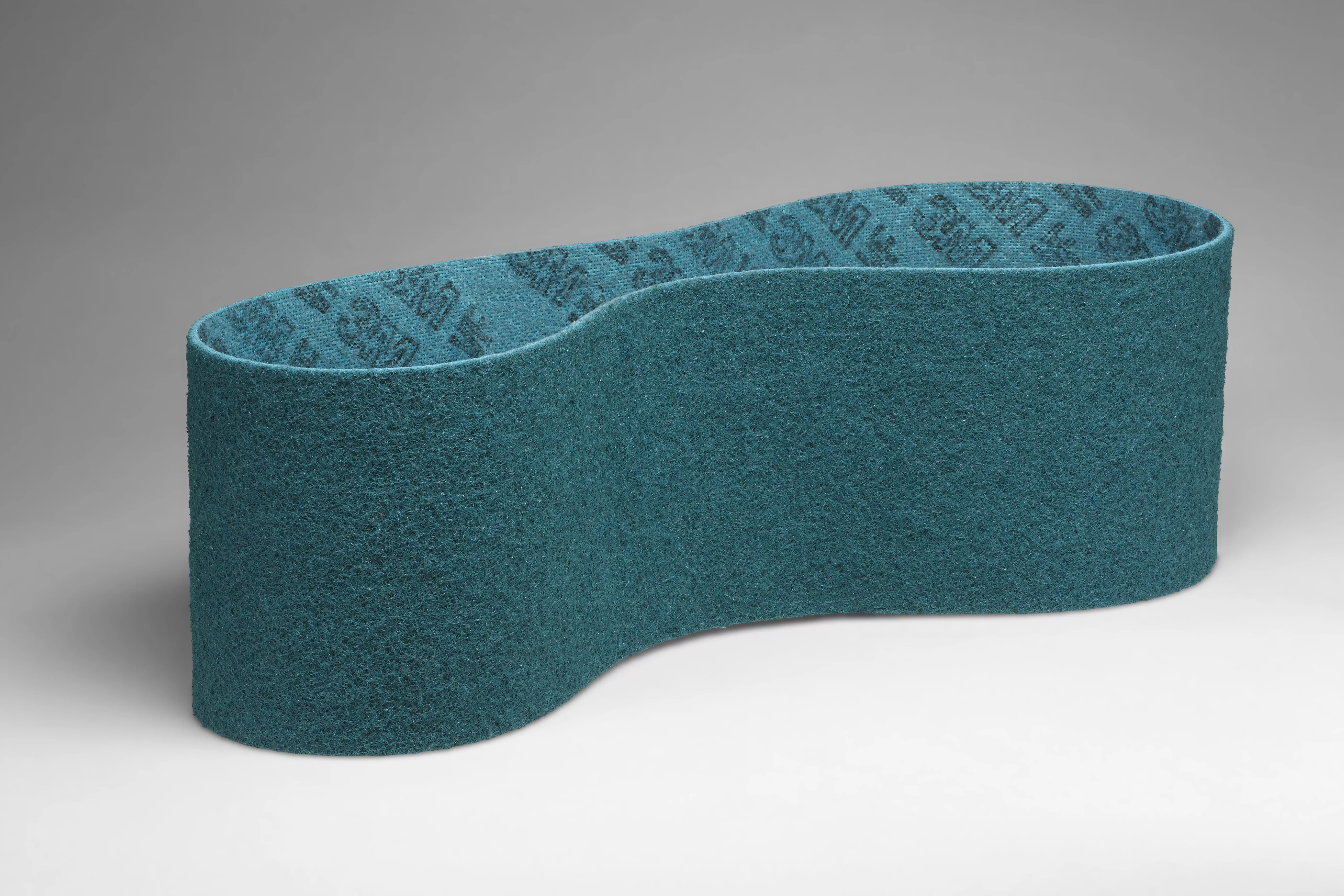

The Many Benefits of Open Web AbrasivesScotch-Brite industrial abrasives stand out due to their unique nonwoven technology. These abrasives are made up of a combination of fiber strands, resin, and abrasive minerals, creating a thick, open web structure. The spring-like nature of the fibers allows them to respond to contours effectively, removing unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece. This, in turn, reduces the need for rework and enhances productivity.

The gaps in the web structure allow swarf to escape, preventing debris from clogging the abrasive mineral. Additionally, the fibers in the web continually break down with use, revealing fresh mineral for consistent and superior cut performance. This exceptional consistency, combined with an extremely long service life, makes Scotch-Brite abrasives a reliable choice for a wide range of applications, including aesthetic finishing, weld blending, deburring, and more. These abrasives work quickly and deliver consistent results, ensuring high-quality finishes on every part.

Scotch-Brite Surface Conditioning BeltsOverall, Scotch-Brite Surface Conditioning Belts are the go-to choice for operators when it comes to cleaning, finishing, blending, and deburring tasks. The combination of non-woven material and abrasive grain makes these belts perfect for achieving excellent finishes or removing burrs while maintaining the workpiece's geometry. Trust Scotch-Brite Belts to deliver fantastic results, enhancing productivity and ensuring consistent quality from part to part.