| SKU | 7100169960 |

|---|---|

| Legacy SKU | 61500401171 |

| UPC | 00638060053942 |

| Product Number | SC-BL |

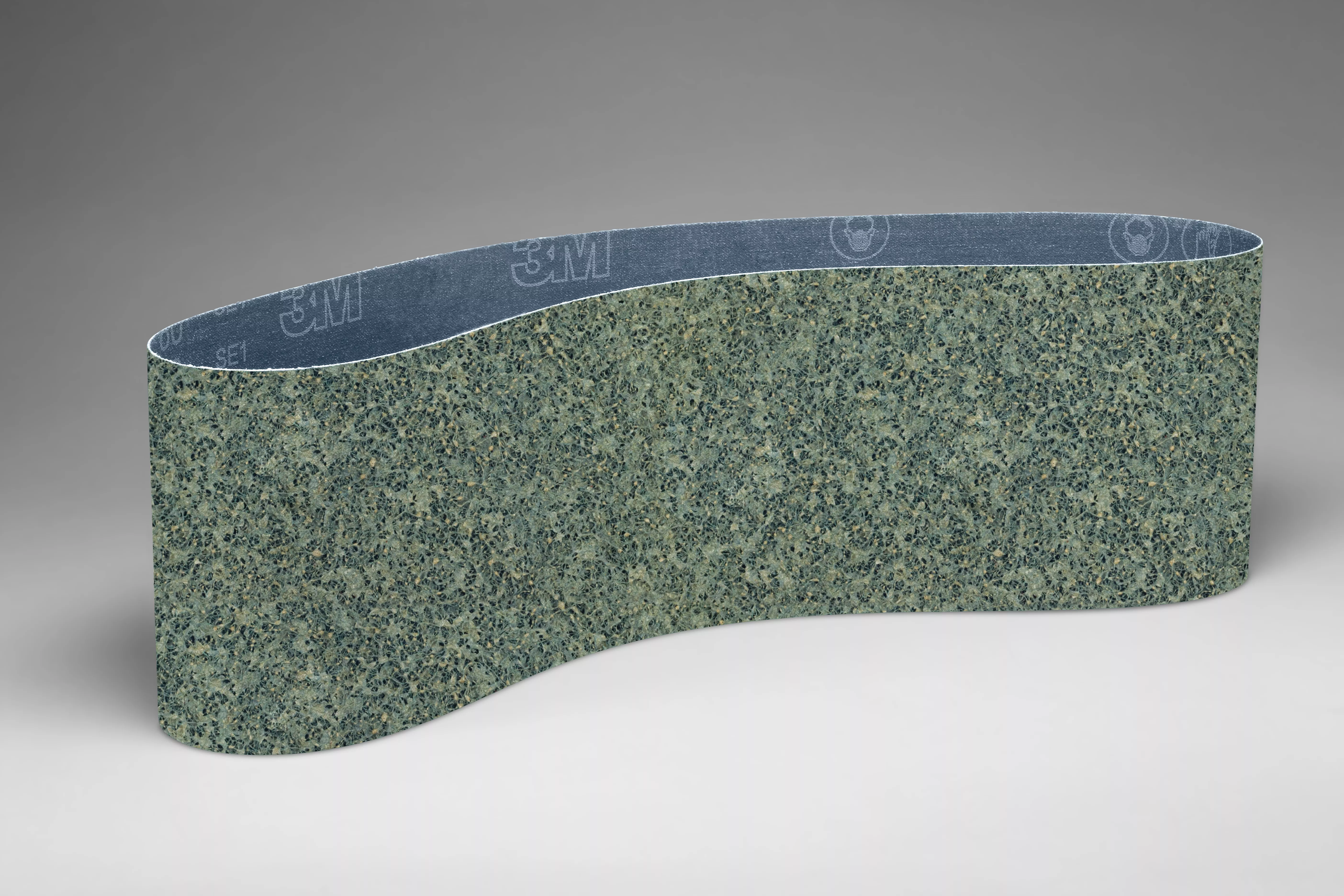

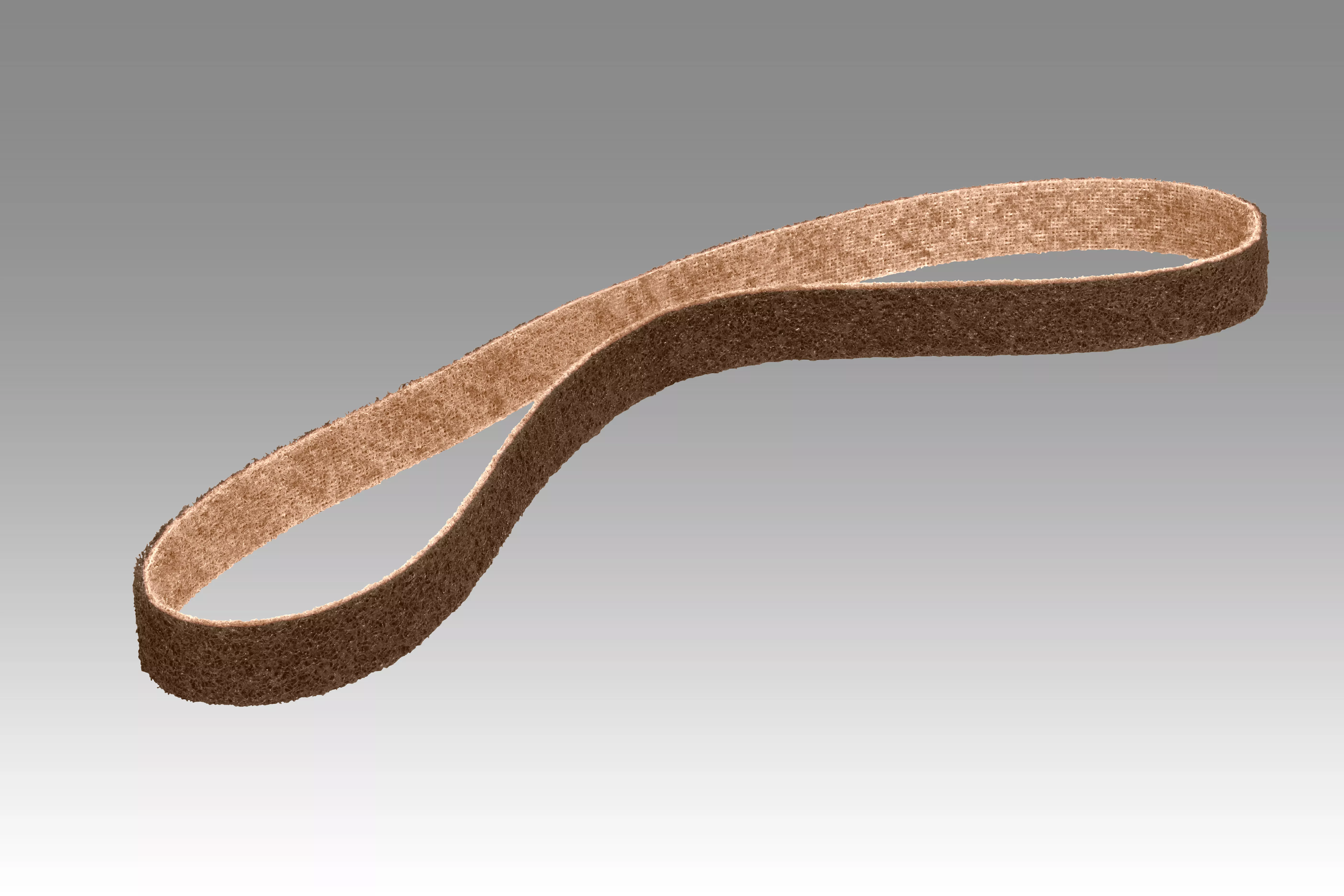

Among Scotch-Brite Surface Conditioning Belts, the Scotch-Brite Surface Conditioning Low Stretch Belt falls right in the middle in terms of its durability and flexibility. Its moderate strength makes it versatile and useful in many sequences cutting aggressively without marring the substrate.

- Durable cloth / polyester scrim backing is ideal for low-stretch applications

- May be used on a variety of substrates, from stainless steel to brass

- Available in a variety of minerals, grades and belt types, so operators can choose the right combination for their application

- Springy non-woven nylon fibers finish while maintaining the geometry of the piece

- Open web is load resistant, prolonging abrasive service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 21.7 lb |

|---|---|

| Length | 53.58268 in |

| Width | 11.69291 in |

| Height | 17.99213 in |

PRODUCT FAQ

-

What is the material used in the Scotch-Brite™ Surface Conditioning Low Stretch Belt?

The Scotch-Brite™ Surface Conditioning Low Stretch Belt consists of aluminum oxide abrasive particles bonded to a durable low-stretch backing.

-

How long is this belt?

The 3M Scotch-Brite™ Surface Conditioning Low Stretch Belt measures 64 inches by 102.375 inches.

-

How many pieces come in a case, and is it readily available for purchase?

Each case contains one unit of Restricted (VFN) grade belt. If you are looking to make a purchase or have any doubts about availability, please reach out to us at [insert contact details] so we can help you place an order.

-

For which surfaces should I use this belt on?

This high-quality surface conditioning belt works well across an array of metals, including stainless steel, carbon steel, alloys, bronze/bass/copper or chrome-plated materials.

-

. Can this product be customized according to my business needs?

. Yes! We offer custom sized belts if needed, please feel free to share your requirements with our team and we will provide further assistance on how best we can serve you!

The Scotch-Brite™ Surface Conditioning Low Stretch Belt is a durable and flexible solution for cleaning, finishing, and light deburring applications. It is most effective on steel and stainless steel, carbon, titanium, and nickel alloys, but can also be used on aluminum, copper, brass, and soft, non-ferrous metals. With many variations available, operators can find the perfect belt for their unique project.

Minerals, Grades and Belt TypesThe Scotch-Brite™ Surface Conditioning Low Stretch Belt is engineered using aluminum oxide and silicon carbide minerals. Combinations include: aluminum oxide medium (A MED), aluminum oxide very fine (A VFN), aluminum oxide coarse (A CRS), silicon carbide medium (S MED), silicon carbide super fine (S SFN), silicon carbide very fine (S VFN). Aluminum oxide is softer but lasts longer than silicon carbide, making it ideal for projects where a soft scratch is desirable. Silicon carbide, on the other hand, is a good match for projects where a coarser, more aggressive cut is desired. Choose a fine grade for finer finishes and medium or coarse grades for coarser finishes. The Scotch-Brite™ Surface Conditioning Low Stretch Belt is intended for use in "low stretch" applications when a standard scrim belt is stretching on the machine or when less conformability is desired. The low-stretch belt is resistant to wear and sharp edges, making it useful in a variety of industries, from transportation to metal fabrication.

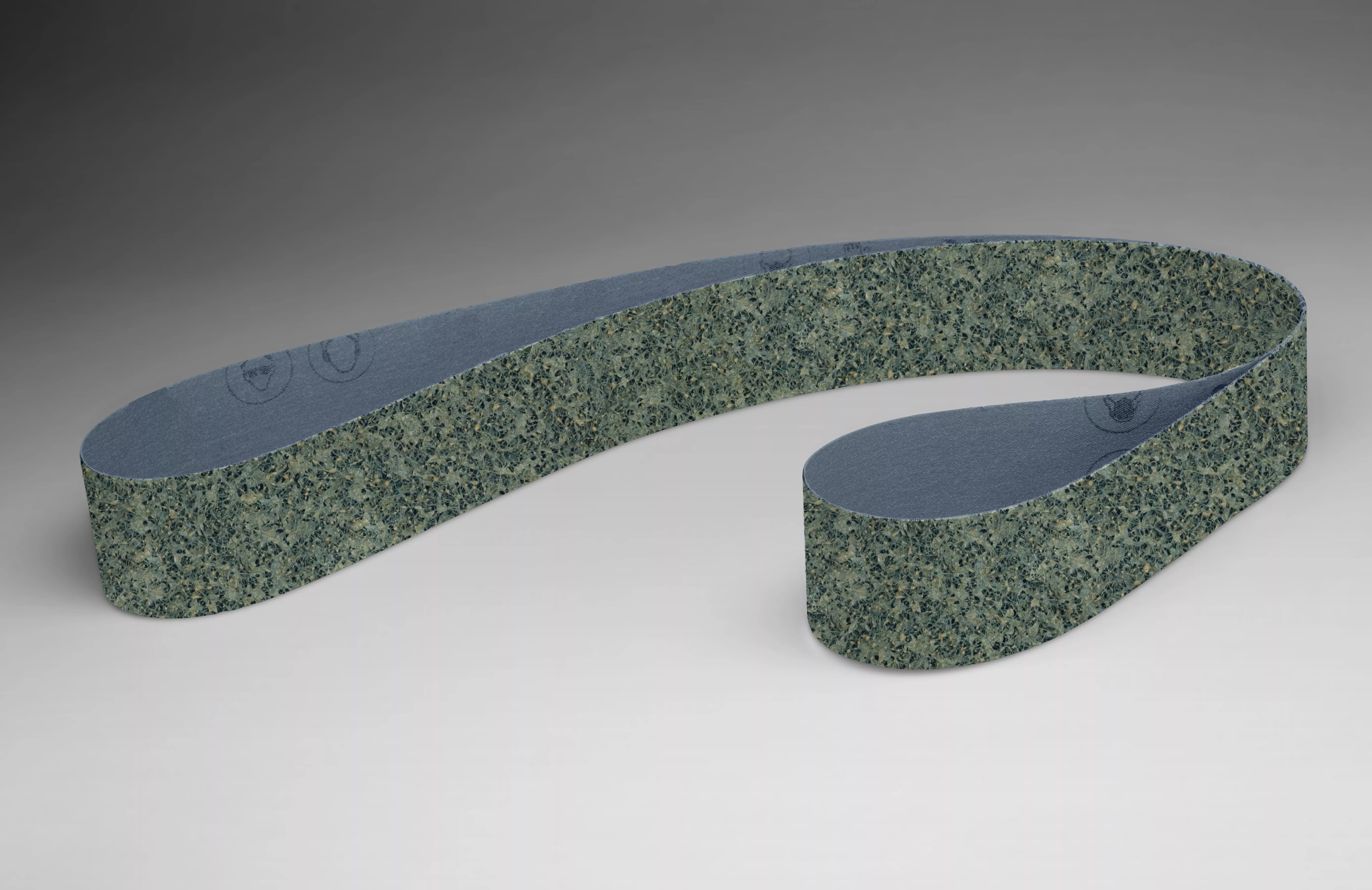

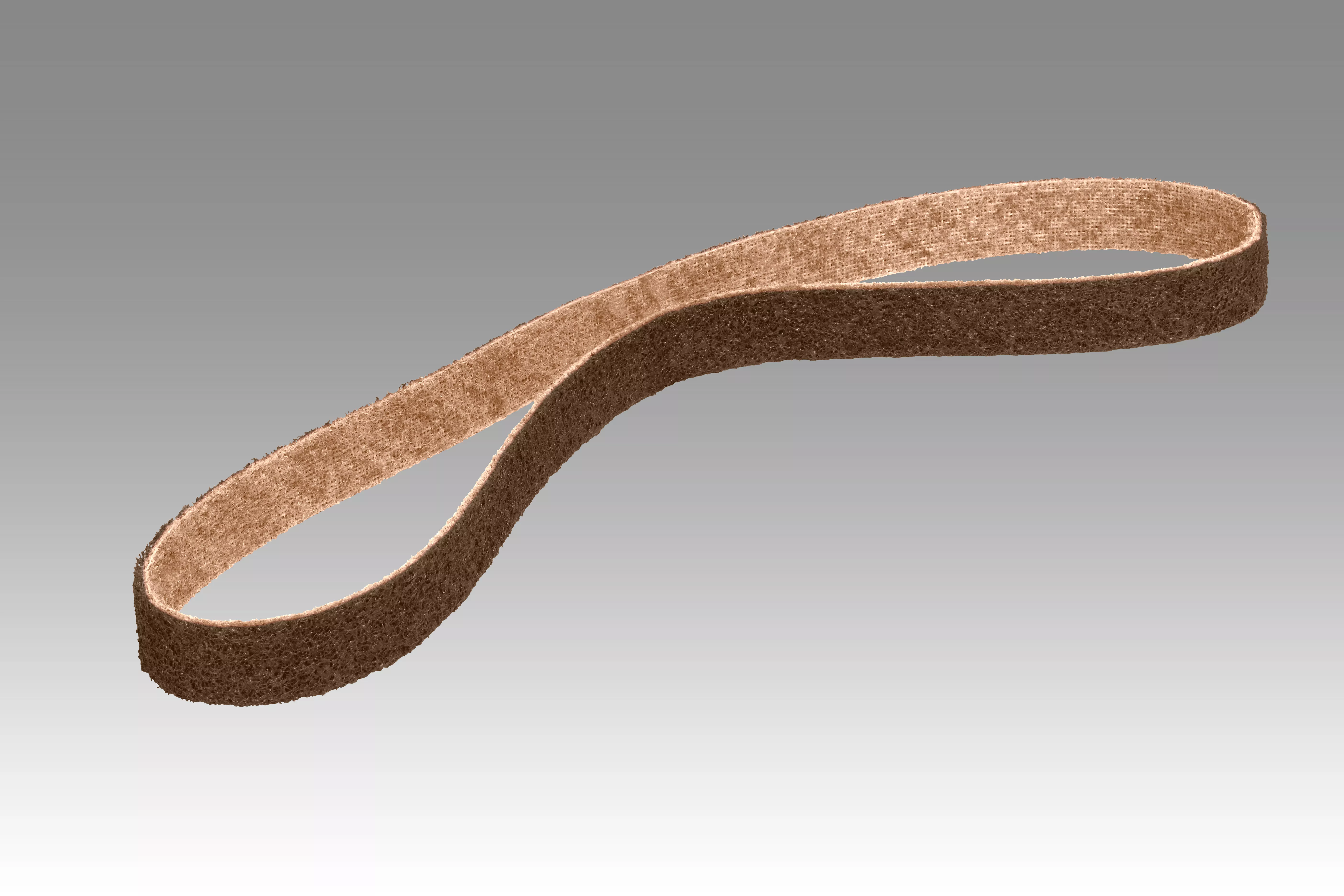

The belt is available in different types: file, narrow, portable, pump sleeve, and wide & flat finishing. Operators should consider tools, surface area, contours, and dimensions of a workpiece when choosing a belt. Narrow belts are commonly used in benchstand and backstand applications, while pump sleeves are fitted around expander wheels and used for finishing large equipment that cannot be moved.

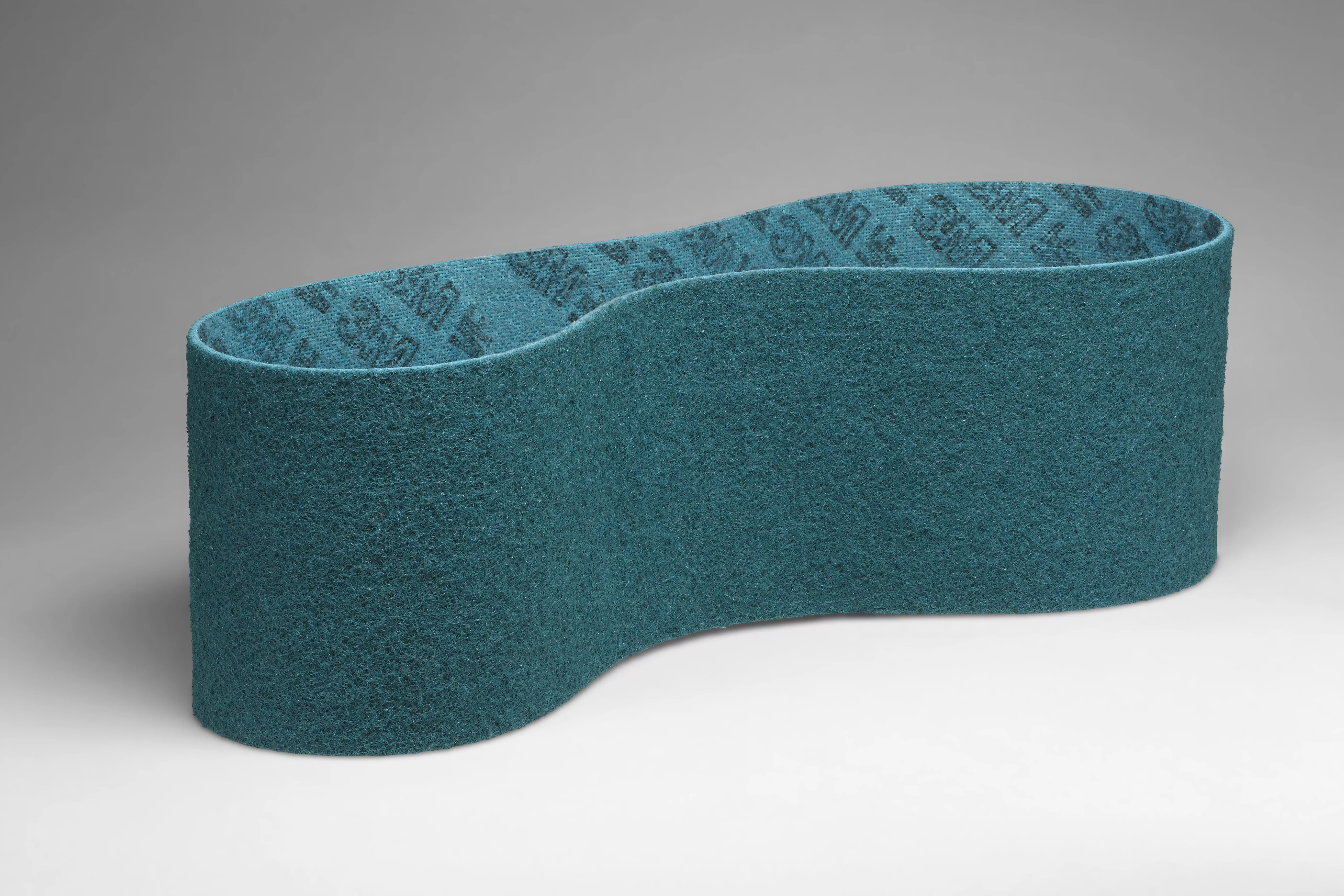

The Many Benefits of Open Web AbrasivesScotch-Brite™ industrial abrasives are unique due to their nonwoven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products not only enhance productivity but also increase operator satisfaction. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Scotch-Brite™ Surface Conditioning BeltsOverall, operators choose Scotch-Brite™ Surface Conditioning Belts for cleaning, finishing, blending, and deburring. The non-woven material combined with abrasive grain is an ideal way to add a great finish or remove burrs while maintaining the geometry of the workpiece. Trust Scotch-Brite™ Belts to deliver fantastic finishes.