| SKU | 7100167141 |

|---|---|

| Legacy SKU | 60440332785 |

| UPC | 00076308456238 |

| Product Number | 244E |

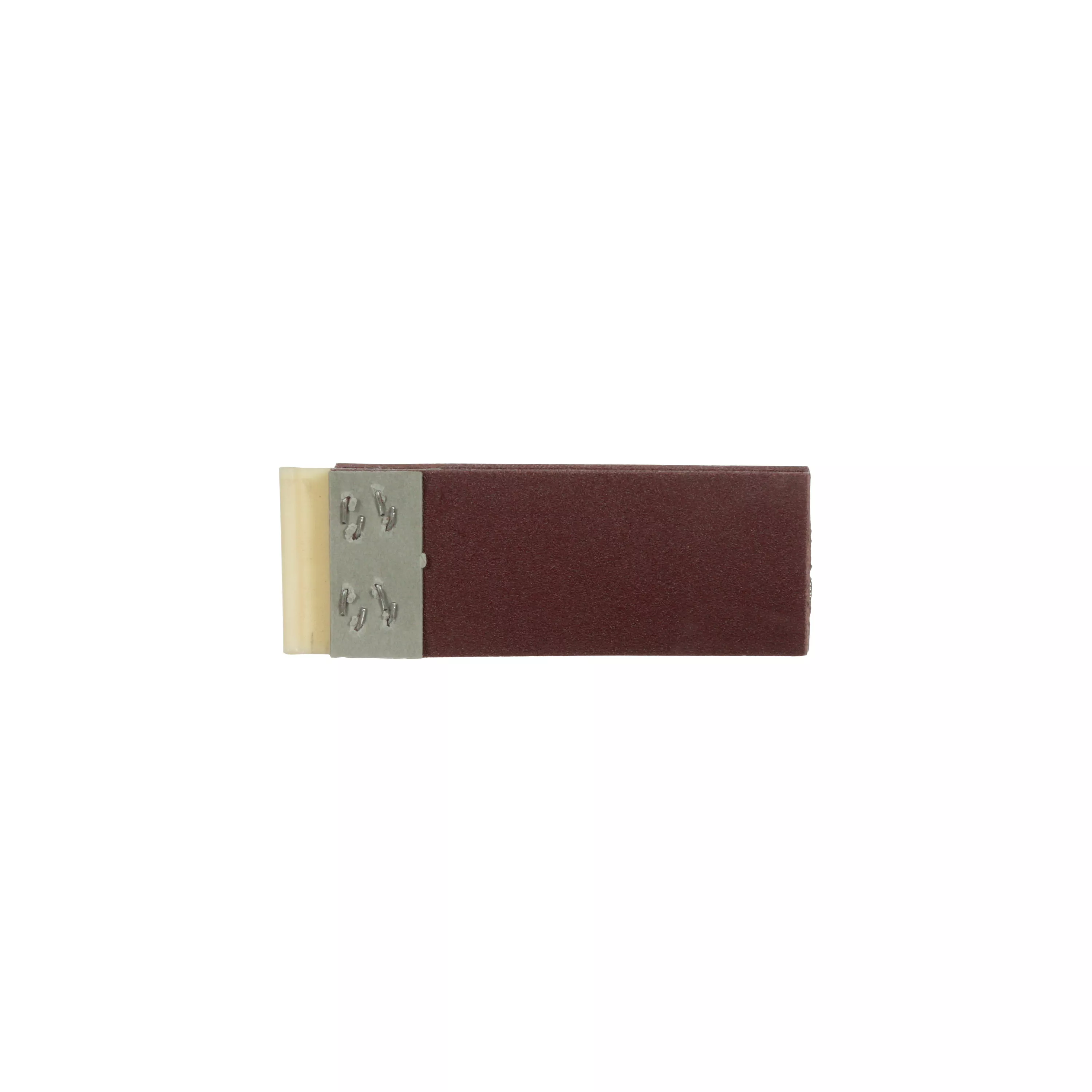

3M Flap Wheel 244E is a general purpose flap wheel that's great for blending, deburring, dimensioning and descaling; it's especially suited for use on soft metals like carbon steel.

- Flap wheel construction minimizes chatter risk

- Aluminum oxide mineral cuts sharp but leaves soft, brushed finishes

- XE-weight rayon backing resists edge wear, so abrasive can stand up to workpiece contours

- Works well on soft metals like carbon steel

- Resin bonded for heat resistance

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 8 in | 203.2 mm |

| Center Hole Diameter | 1-1/4 in | 31.75 mm |

Shipping Dimensions |

|

| Weight | 9.599 lb |

|---|---|

| Length | 9 in |

| Width | 9 in |

| Height | 13.6 in |

| Grit | 80 |

|---|

PRODUCT FAQ

-

What is the size of the 3M™ Flap Wheel 244E?

The 3M™ Flap Wheel 244E has dimensions of 8 inches by 4 inches by 1-1/4 inches.

-

What grade or weight is the abrasive material in this wheel?

The abrasive material used in the 3M™ Flap Wheel 244E is XE-weight, which refers to its Extra Heavyweight designation.

-

How many flap wheels are included in one case?

Each case of the 3M™ Flap Wheel 244E contains one flap wheel.

-

Can you tell me what grit level or coarseness this flap wheel offers?

The grit level for this particular flap wheel is rated at an industry-standard coarse level of 80.

-

Is there any additional information I should know about this product's usage or application?

This flap wheel from our trusted brand, when mounted on a suitable tool (like a bench motor), can smoothly and effectively blend, deburr, and polish various metal surfaces. It's designed for long-lasting performance and excellent results.

The 3M™ Flap Wheel 244E is designed with abrasive flaps attached to a steel core filled with resin. This unique construction minimizes the risk of chatter and marks. The flaps rotate centrifugally and make continuous contact with the workpiece, eliminating residual traces or marks left by singular discs or discs ganged on a shaft. The abrasive flaps provide a long-lasting supply of fresh mineral and a load-resistant design. As the flaps spin, they remove unwanted swarf and debris from the substrate, leaving a smooth, brushed finish. The 3M™ Flap Wheel 244E can be used with various tools, including a backstand, match and finish sander, and a centerless grinder.

Cuts Sharp, Leaves a Fine FinishThe flaps on the 3M™ Flap Wheel 244E are made with aluminum oxide mineral. Aluminum oxide is a popular choice in grinding applications due to its cut-rate and long life. Its hardness, strength, and low heat retention make it ideal for industrial professionals. The wheel is available in grades 60-120, allowing operators to choose the right grade for their specific project. Coarser grades (60) are suitable for substrates that require a deeper scratch, while finer grades (120) are ideal for substrates that require a soft, fine scratch. The mineral is bonded to the flaps with resin, which gradually dissolves as the wheel spins, helping the abrasive withstand heat and maintain its strength. The abrasives flaps on the 3M™ Flap Wheel 244E have an XE-weight rayon backing, providing flexibility and resistance to edge wear.

Resulting in Fine, Brushed FinishesWhen it comes to descaling, setting the grain, refining, or blending workpieces, it is crucial to have an abrasive that can withstand wear and tear without compromising part geometry. The 3M™ Flap Wheel 244E is specifically designed to produce fine, brushed finishes on soft metals, ensuring high-quality results.