| SKU | 7100074414 |

|---|---|

| Legacy SKU | 60440275091 |

| UPC | 00051144350865 |

| Product Number | 244E |

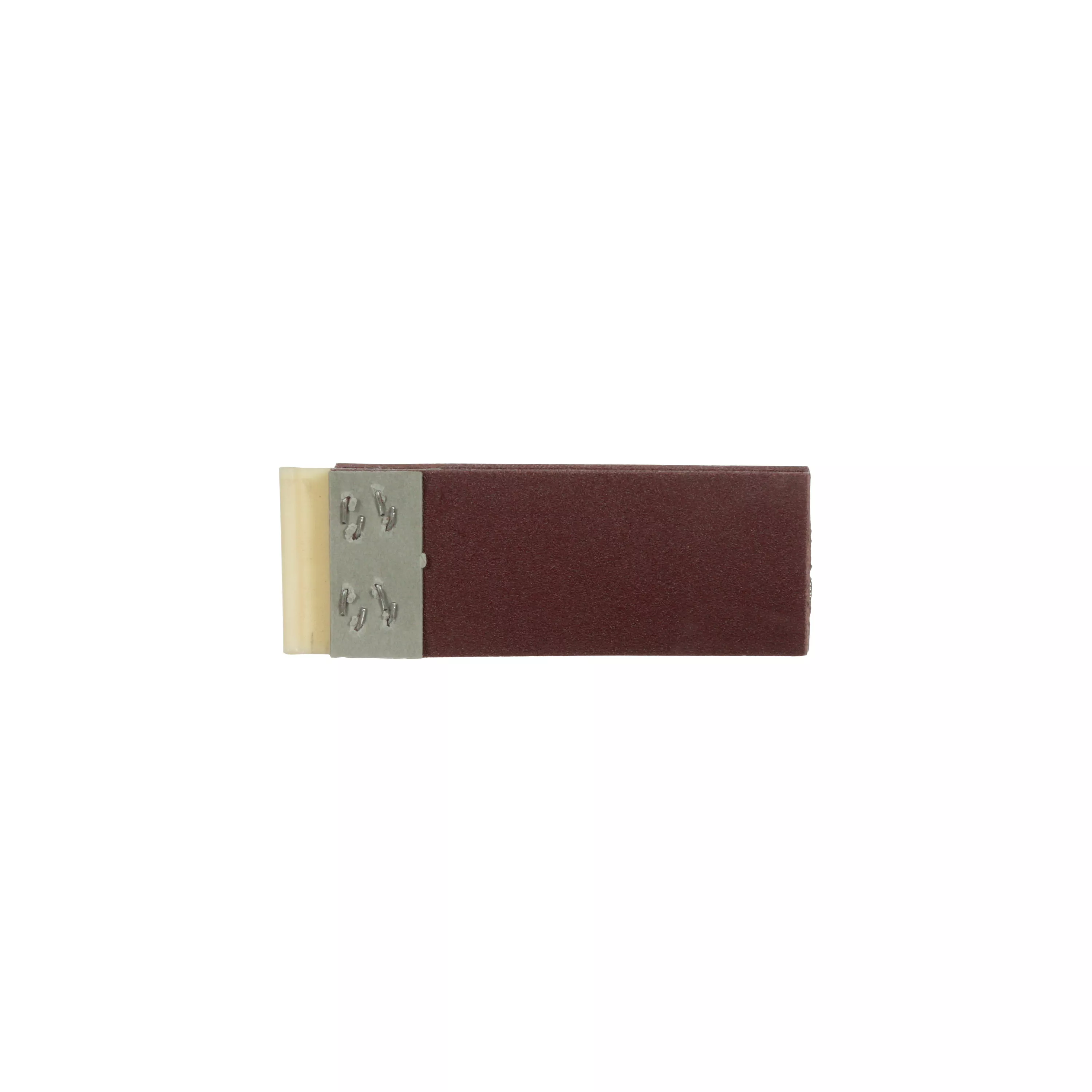

3M Flap Wheel 244E is a general purpose flap wheel that's great for blending, deburring, dimensioning and descaling; it's especially suited for use on soft metals like carbon steel.

- Flap wheel construction minimizes chatter risk

- Aluminum oxide mineral cuts sharp but leaves soft, brushed finishes

- XE-weight rayon backing resists edge wear, so abrasive can stand up to workpiece contours

- Works well on soft metals like carbon steel

- Resin bonded for heat resistance

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 8.79997 lb |

|---|---|

| Length | 14.01575 in |

| Width | 14.01575 in |

| Height | 4.80315 in |

| Grit | 80 |

|---|

PRODUCT FAQ

-

What is the 3M™ Flap Wheel 244E made of?

The 3M™ Flap Wheel 244E is made of aluminum oxide abrasive materials which provide a fast, consistent cut on high-pressure applications.

-

What size options are available for the product?

This flap wheel comes in a standard size of 6 inches by 2 inches and has a width or thickness of one inch. It fits most bench grinders and other similar machines.

-

How many pieces come in each purchase case?

Each purchase case contains five pieces of the same specification - an80 XE-weight flap wheel measuring six inches by two inches by one inch, to cater for different customer needs.

The 3M™ Flap Wheel 244E is designed with abrasive flaps adhered to a steel core filled with resin. This unique construction minimizes the risk of chatter and marks. The flaps rotate centrifugally and make continuous contact with the workpiece, eliminating residual traces or marks left by singular discs or discs ganged on a shaft. The abrasive flaps offer a long-lasting supply of fresh mineral and a load-resistant design. As the flaps spin, they help rid the substrate of unwanted swarf and debris, leaving a smooth, brushed finish. The 3M™ Flap Wheel 244E can be used with a variety of tools, including a backstand, match and finish sander, and a centerless grinder.

Cuts Sharp, Leaves a Fine FinishThe flaps on the 3M™ Flap Wheel 244E contain aluminum oxide mineral, which is a popular choice among industrial professionals due to its cut-rate and long life. Its hardness, strength, and low heat retention make it a good choice in grinding applications. The mineral is available in grades 60-120, allowing operators to choose the right grade for their unique project. Coarser grades (60) are desirable for substrates that require a deeper scratch, whereas finer grades (120) are desirable for substrates that require a soft, fine scratch. The mineral is bonded to the flaps with resin, which dissolves gradually as the wheel spins, helping the abrasive withstand heat and stay strong while it works. The abrasives flaps on the 3M™ Flap Wheel 244E have an XE-weight rayon backing, making them more flexible and resistant to edge wear.

Resulting in Fine, Brushed Finishes3M™ Flap Wheel 244E is ideal for descaling, setting the grain, refining, or blending workpieces. It's important to have an abrasive that can withstand wear and tear without compromising part geometry, and that's where 3M™ Flap Wheel 244E comes in. It produces fine, brushed finishes on soft metals.