| SKU | 7010361113 |

|---|---|

| Legacy SKU | 60440235756 |

| UPC | 00051141282084 |

| Product Number | 236U |

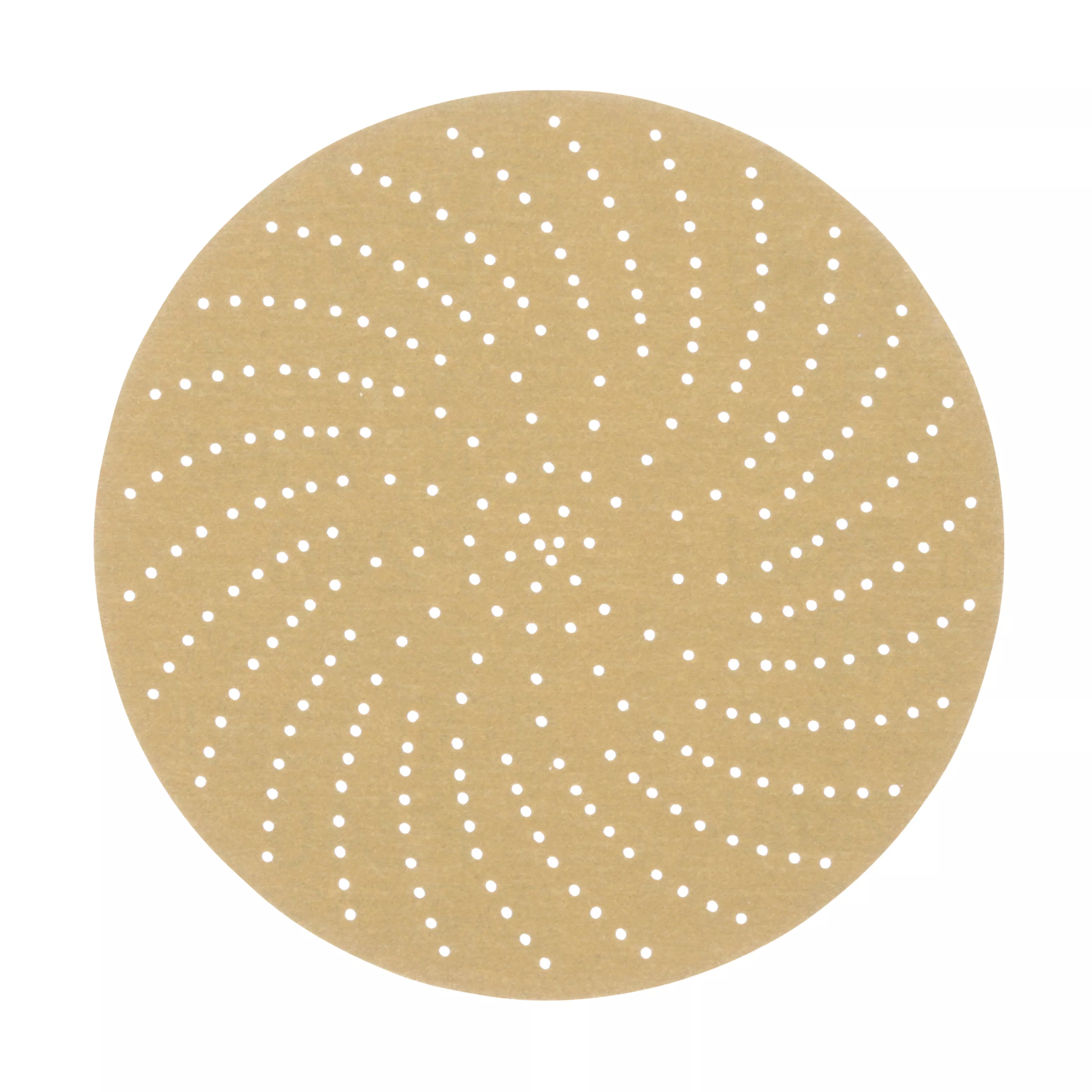

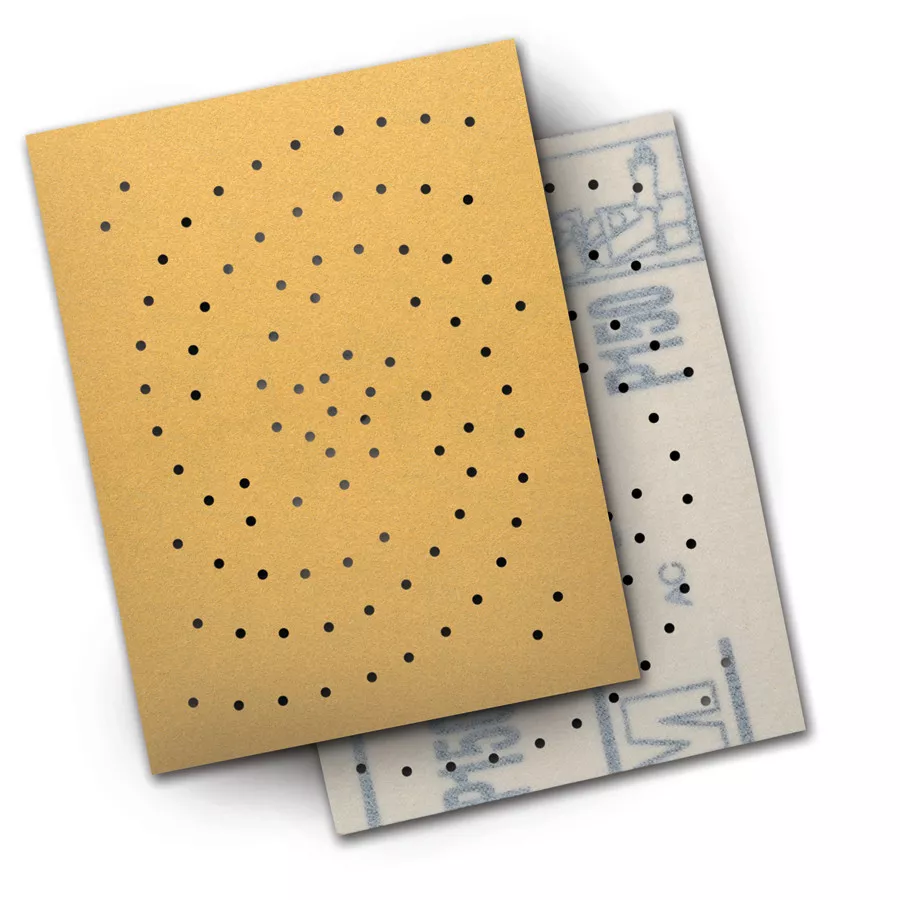

3M Stikit Paper Disc Roll 236U offers a versatile disc with a convenient adhesive backing ready for quick and easy attachment to a 3M Stikit backup pad (sold separately). The roll offers quick access to a disc and eliminates disc liners. The disc features a strong, C-weight paper backing that resists wear during aggressive sanding.

- Adhesive backing allows for quick application and easy removal

- Convenient disc rolls eliminate the need to remove disc liners from individual discs

- Strong, C-weight paper backing provides extra durability when compared to lighter weight paper backings

- Aluminum oxide mineral is durable, cuts fast, and performs well on many surfaces

- Load-resistant coating helps prevent premature loading of the disc surface to maximize cut and extend the life of the abrasive grains

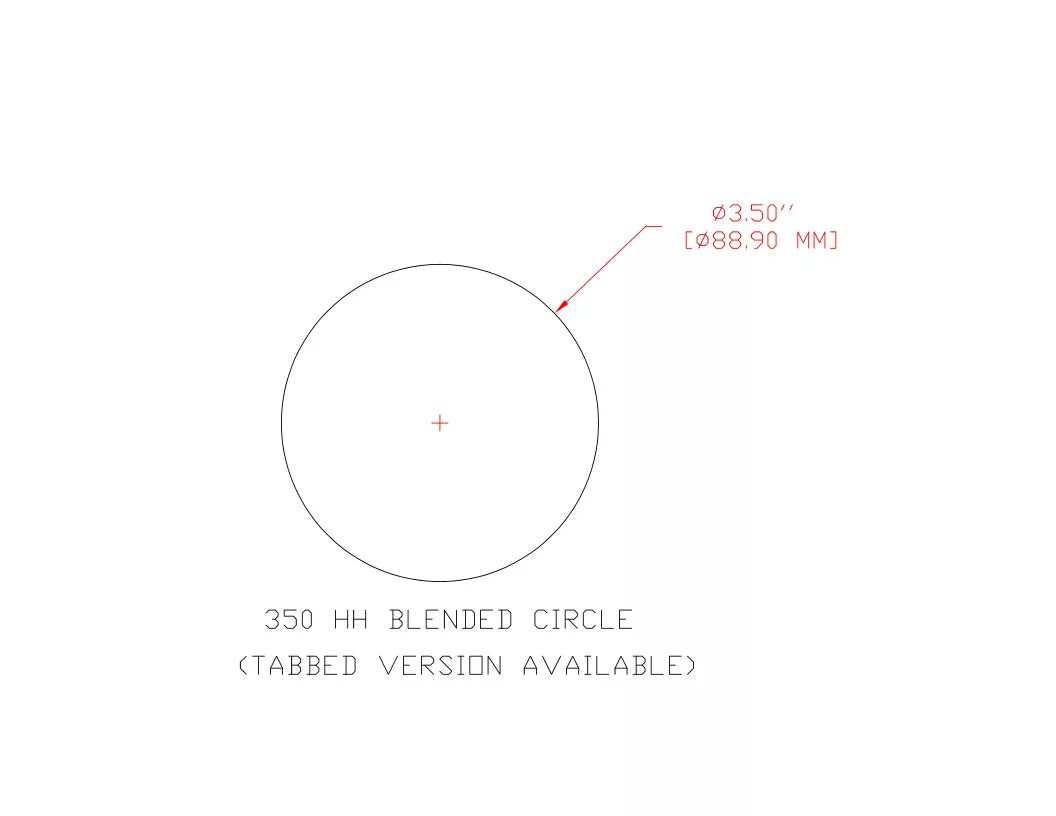

Product Dimensions |

Imperial | Metric |

| Weight | 0.75 lbs | |

|---|---|---|

| Width | 3.3748 in | |

| Length | 3-3/8 in | |

| Height | 6-1/8 in | |

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0 NP |

Shipping Dimensions |

|

| Weight | 3.49874 lb |

|---|---|

| Length | 13 in |

| Width | 8.8 in |

| Height | 4.8 in |

| Color | Gold |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Stikit™ Paper Disc Roll 236U made of?

The 3M™ Stikit™ Paper Disc Roll 236U is made of high-quality paper material with an abrasive coating.

-

What grit grade does the P220 C-weight disc roll have?

The P220 C-weight disc roll features a medium-grit abrasion power suitable for sanding surfaces before finishing it.

-

How many discs are in each roll and per case, respectively?

Each 3M™ Stikit™ Paper Disc Roll comprises a total of one hundred (100) discs while four rolls come as one case producing a total count of four hundred (400).

-

Is there any liner included in this type of product in terms of packaging and storage purposes?

. Yes, each disk comes with a Linered back that helps to protect pressure-sensitive adhesive (PSA) coating on the underside from contaminants like dust or dirt during storage or transportation.

-

. Are there any restrictions applying when using this product?

. Yes, just like every other industrial device out there, this product falls under restricted equipment regulations within certain countries due to compliance issues such as VOC standards and Hazardous air pollutants among others prompting users to check their local regulatory requirements before purchasing/using the product.

The 3M™ Stikit™ Paper Disc Roll 236U is a high-quality, coated abrasive product that is designed to handle a wide range of sanding and finishing needs. The open-coat construction and load-resistant coating help prevent clogging to maximize cut and the useful life of the disc. This product can be used for sanding and finishing on many different surfaces, such as paint, primer, softwood, metal, plastic, hard and soft composites, and fiberglass.

3M™ Stikit™ discs come ready to use with a pressure sensitive adhesive coating on the backside so they conveniently press on to the backup pad, and remove cleanly, leaving an uncontaminated surface for the next disc. The Stikit™ disc should be used in conjunction with the 3M™ Stikit™ backup pad (also called a disc pad and sold separately) that is attached to a disc sander, random orbital sander, or stationary disc sander.

Aluminum oxide is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut-rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys.

3M™ Stikit™ Paper Discs feature a load-resistant coating that allows the disc to continue cutting even when sanding softwoods, paints, and other materials that would, otherwise, clog the surface of the disc and hinder sanding ability. An open coat means the abrasive grains are spaced slightly apart so that dust can escape rather than loading the cutting edge of the grains, thereby optimizing cut-rate and disc life.

- High-quality, coated abrasive product

- Open-coat construction and load-resistant coating help prevent clogging

- Can be used for sanding and finishing on many different surfaces

- Pressure sensitive adhesive coating on the backside for easy use

- Aluminum oxide is a popular choice among industrial professionals

- Load-resistant coating allows the disc to continue cutting even when sanding softwoods, paints, and other materials

- An open coat means the abrasive grains are spaced slightly apart so that dust can escape