| SKU | 7010359513 |

|---|---|

| Legacy SKU | 60020003624 |

| UPC | 00051111546246 |

| Product Number | 272LA |

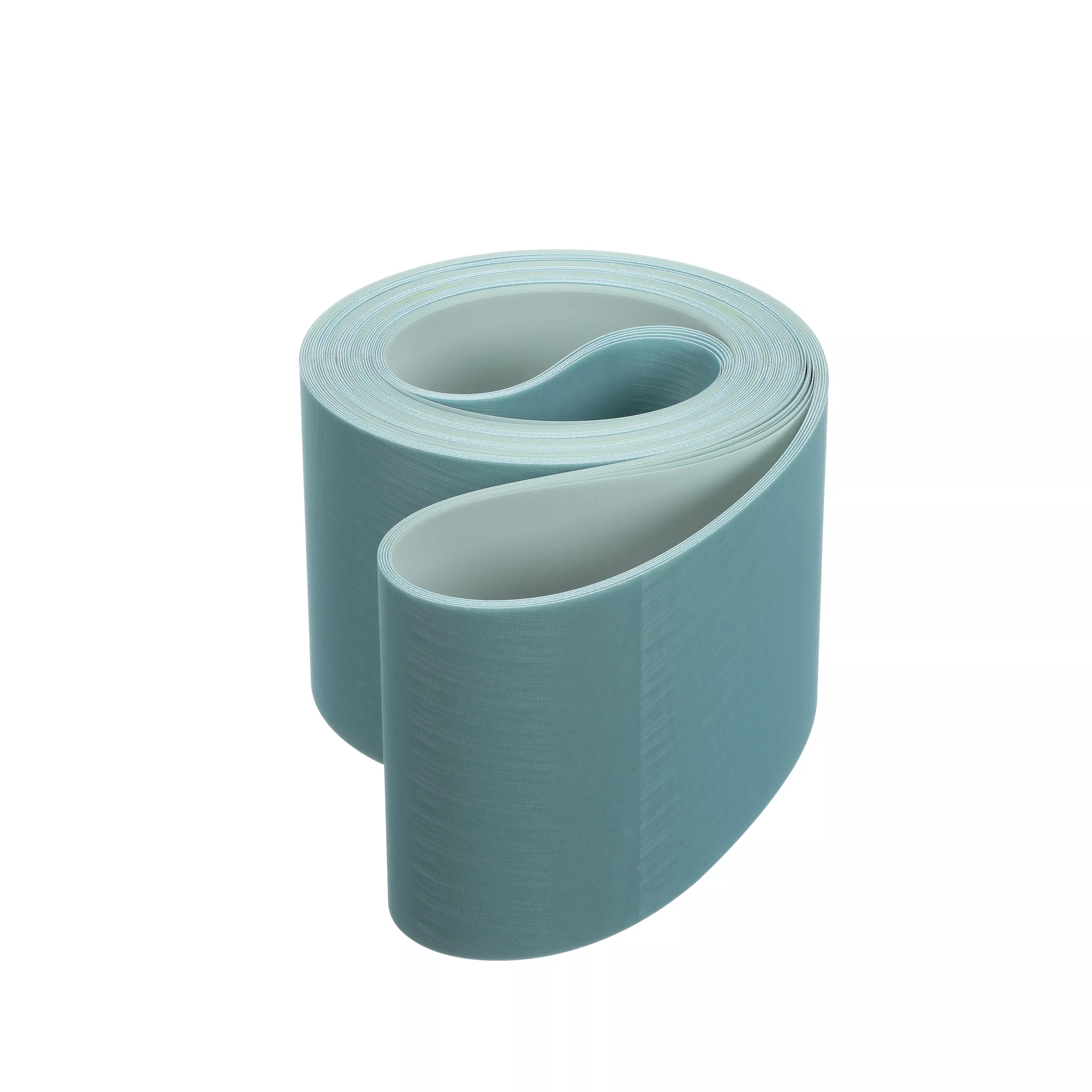

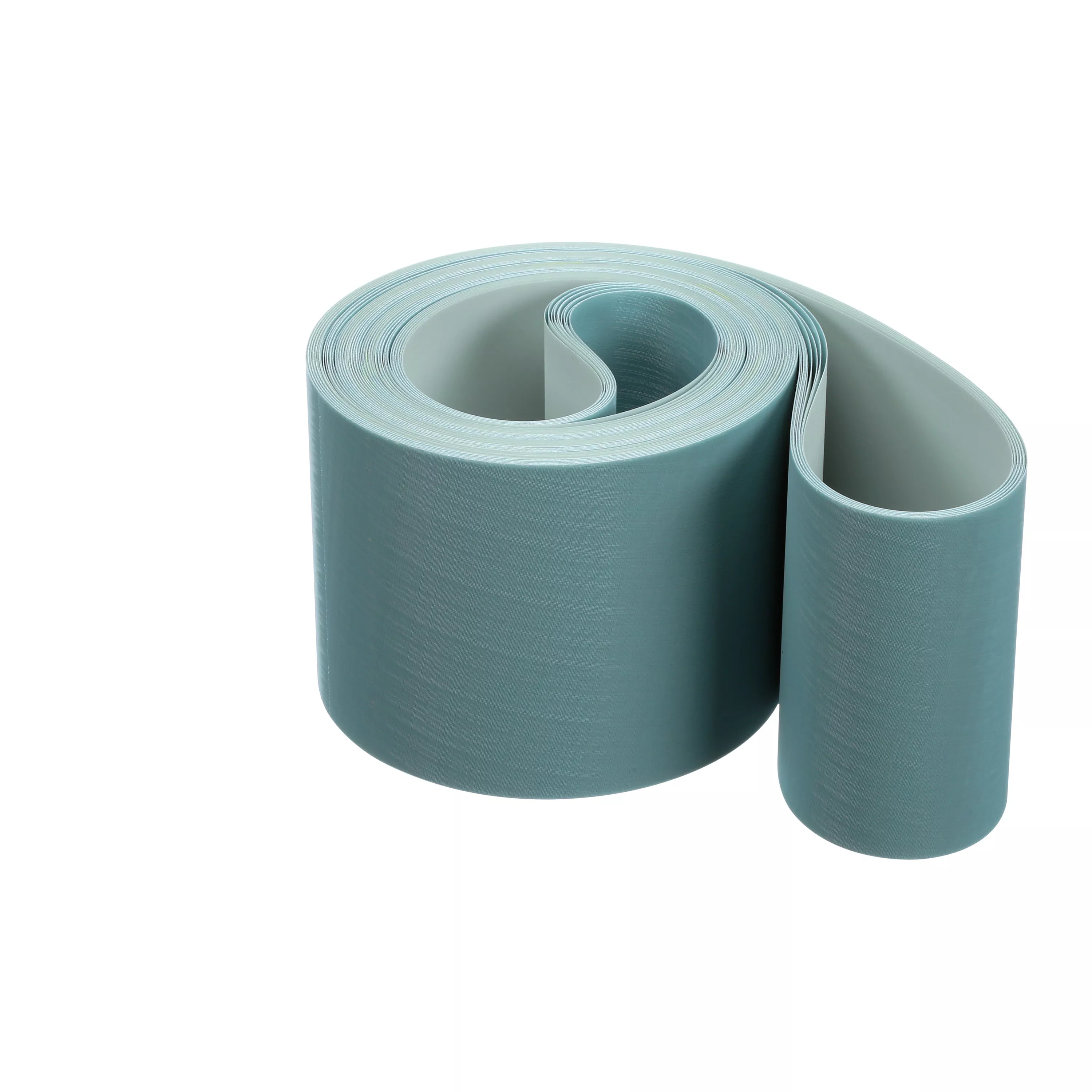

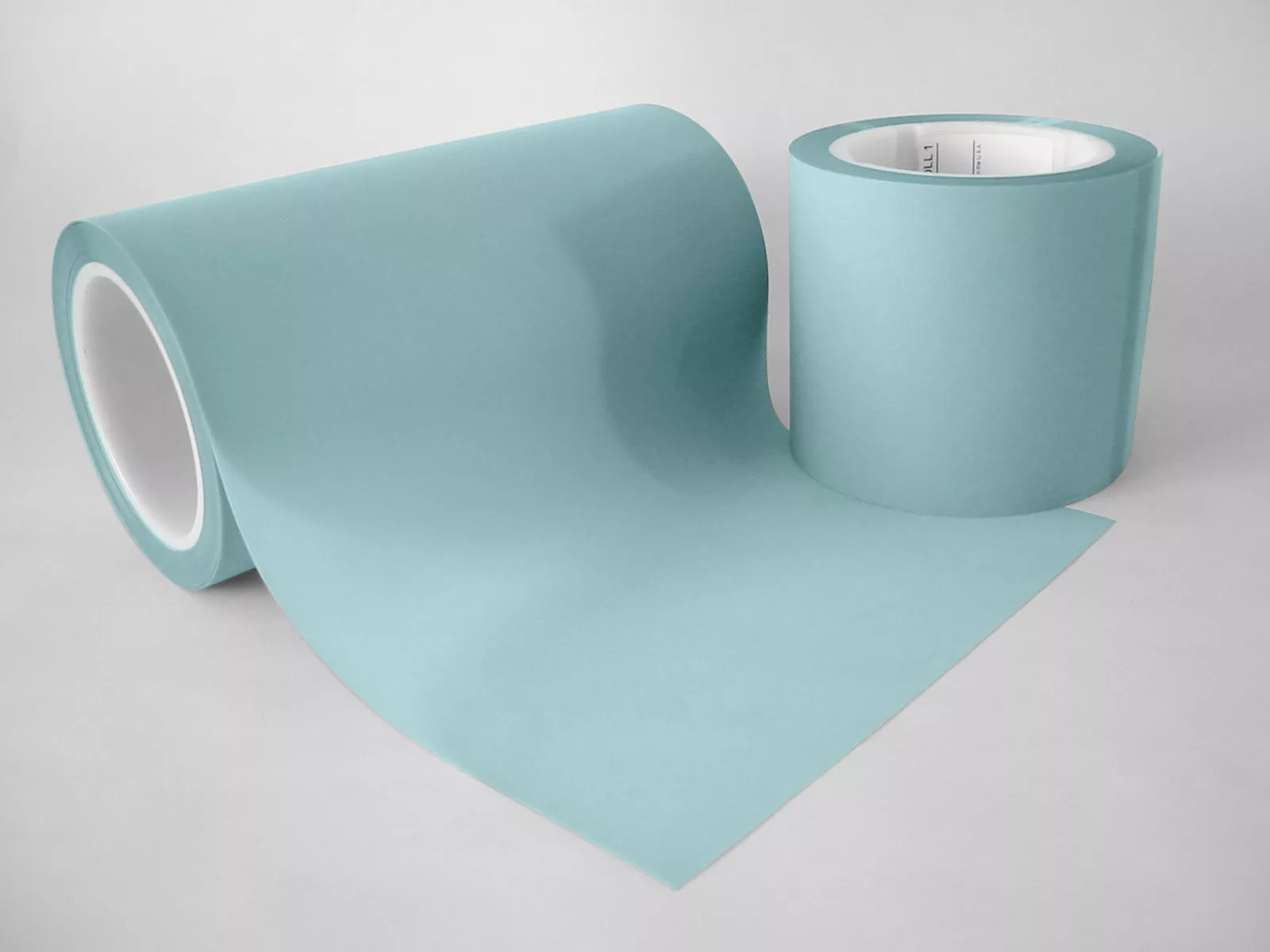

3M Trizact Film Belts 272LA are ideal for repairing defects on glass and finishing Corian and acrylic solid surfaces. Very few processing steps are necessary to achieve high gloss and level surfaces. Uniquely structured abrasive mineral continues to stay sharp and deliver consistently outstanding results.

- Fresh cutting surfaces on abrasive mineral are continually exposed by wear, resulting in extended belt life, reducing frequency of belt changes

- Fewer processing steps means you save production time

- Microreplicated abrasive delivers precise, repeatable finishes and higher gloss level

- Film backing ensures consistently finer finishes

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 20.58 lb |

|---|---|

| Length | 12 in |

| Width | 12 in |

| Height | 7 in |

| Color | Blue |

|---|

PRODUCT FAQ

-

What is the Trizact Film Belt 272LA used for?

The Trizact Film Belt 272LA is designed to be used for refining scratches left from previous abrasive steps, achieving consistent finishes on hard and soft metals.

-

How many belts are included in each case of the 3M™ Trizact™ Film Belt 272LA?

Each case of the 3M™ Trizact™ Film Belt 272LA includes twenty (20) belts.

-

Can this belt be used wet or dry?

Yes, you can use the Trizact Film Belt 272LA with either a wet or dry application method.

3M™ Trizact™ Film Belts are designed with a resilient film backing coated with a uniquely structured aluminum oxide mineral. The abrasives are produced using a proprietary 3M technology called microreplication, which ensures that the abrasives start sharp and stay sharp, delivering a more consistent cut and finish over their lifetime. The aluminum oxide mineral is contained in pyramid-like microreplicated features that are evenly distributed across a backing in a precise pattern. As the peaks of these structures wear away, fresh cutting mineral is exposed, ensuring a fast, consistent cut rate.

Greater Productivity, More Desirable FinishesTrizact™ abrasives are unlike conventional abrasives, which are constructed from randomly-spaced and irregularly shaped minerals. The uniform configuration of Trizact™ abrasives helps deliver more consistent, predictable finishes, higher, more even rates of cut, cooler grinding and finishing temperatures, and ultimately, fewer processing steps for greater productivity.

The unique construction of Trizact abrasives requires a different grading system. Grade is defined by the average particle size in microns and begins with an "A." Lower grades are finer. The 3M™ Trizact™ narrow film belt is available in A5, A10 and A35 micron grades and widths up to 26 inches.

- 3M™ Trizact™ Film Belts are coated with a uniquely structured aluminum oxide mineral on a resilient film backing.

- Microreplication – a proprietary 3M technology – produces abrasives that start sharp and stay sharp, delivering more consistent cut and finish over their lifetime.

- The uniform configuration of Trizact™ abrasives helps deliver more consistent, predictable finishes, higher, more even rates of cut, cooler grinding and finishing temperatures, and ultimately, fewer processing steps for greater productivity.

- The 3M™ Trizact™ narrow film belt is available in A5, A10 and A35 micron grades and widths up to 26 inches.