| SKU | 7000028112 |

|---|---|

| Legacy SKU | 60020006155 |

| UPC | 00051111562277 |

| Product Number | 272LA |

3M Trizact Film Roll 272LA abrasives are engineered for repairing defects on glass and for finishing Corian and acrylic solid surfaces. A 5 mil film backing provides resilience and flexibility while conforming to irregular profiles on sensitive surfaces. Use wet on reel-to-reel set ups for applications of microfinishing and superfinishing.

- Aluminum oxide in a series of fine grades is designed to effectively level surfaces and remove defects, scratches and stains in metal, glass, and solid surfaces

- Combination of abrasive features is designed to deliver high gloss and luster

- Film backing enables wet operation to minimize dust and support finer finishes

- 3M™ Trizact™ abrasive mineral exposes fresh cutting surfaces as it wears for consistent, predictable cut and finish supporting greater productivity

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 33.99528 lb |

|---|---|

| Length | 7.79528 in |

| Width | 7.79528 in |

| Height | 26.1811 in |

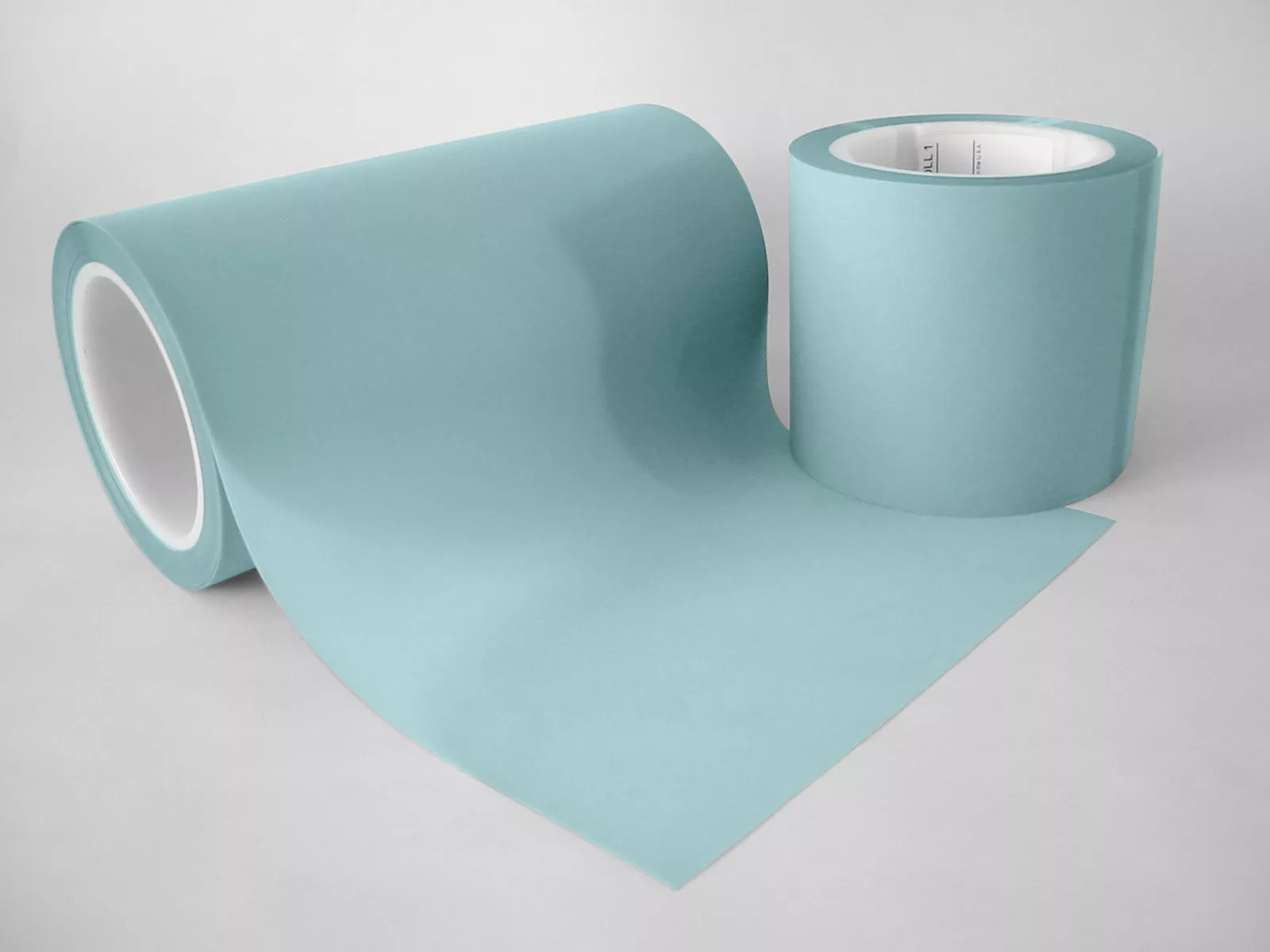

| Color | Blue |

|---|

PRODUCT FAQ

-

What is the composition of the Trizact Film Roll 272LA?

The Trizact Film Roll 272LA is a durable abrasive product made up of micro-replicated structures in a resin bonding, with aluminum oxide mineral particles.

-

Is the Trizact Film Roll suitable for use on any surface?

Yes, it can be used on almost every type of hard material such as metal, glass or ceramic tiles.

-

What are ASO and A10 mean when referring to this product?

Any-Seal-Open (ASO) packing system ensures that you do not have to struggle with difficult-to-remove packaging materials while unwrapping your roll. On the other hand, A10 refers to grit size classification which provides consistent finishes thanks to its foam-bonding technology.

-

How long will one roll last with average usage?

The lifespan of each roll depends upon varying factors like coarseness level and frequency/intensity of use etc., however under normal conditions usage trizact film rolls tend to last much longer than similar based competitor products due to their advanced tri-layered composite construction.

-

:Is there a warranty available for this product?

:Yes! All our products come equipped with standard manufacturer warranties. If there's anything malfunctioning from our side then we'll gladly replace or repair it accordingto company warranty policy , provided it meets regulatory customer terms

3M™ Trizact™ Film Roll 272LA answers the challenges of producing fine finishes and delivering polished surfaces that meet the exacting specifications of fine manufacturing. This product is often used in microfinishing and superfinishing applications that utilize abrasives in reel-to-reel product forms.

3M™ Trizact™ Film Roll 272LA is available in micron grades A35, A10 and A5. The coarsest grade, A35, is used for repairing defects and surface leveling. Progress to grades A10 and A5 to further refine scratches left behind in previous steps. The polyester film backing is waterproof for wet use to minimize dust and resilient enough for industrial applications.

Designed for Glass, Corian and Acrylic Solid SurfacesOriginally designed for glass, corian, and acrylic substrates, this abrasive is among 3M's best for achieving a high gloss level and removing scuffs, scratches and acid marks on countertops, airplane windscreens and windows, architectural glass and other products. 3M™ Trizact™ 272LA can also be very effective on metal substrates for fine finishing and polishing.

The Trizact FormulaThese abrasive products are coated with a uniquely structured aluminum oxide mineral on a resilient film backing. Microreplication – a proprietary 3M technology – produces abrasives that are designed to start sharp and stay sharp, and to deliver more consistent cut and finish over their lifetime. The aluminum oxide mineral in this product is contained in uniquely shaped pyramid-like structure evenly distributed across the backing in a precise pattern. As the peaks of these structures wear away, fresh cutting mineral is exposed. Ultimately, this serves to support a fast, consistent and predictable cut rate throughout the life of the abrasive.