| SKU | 7010325881 |

|---|---|

| Legacy SKU | 60440107294 |

| UPC | 00051144841813 |

| Product Number | 366L |

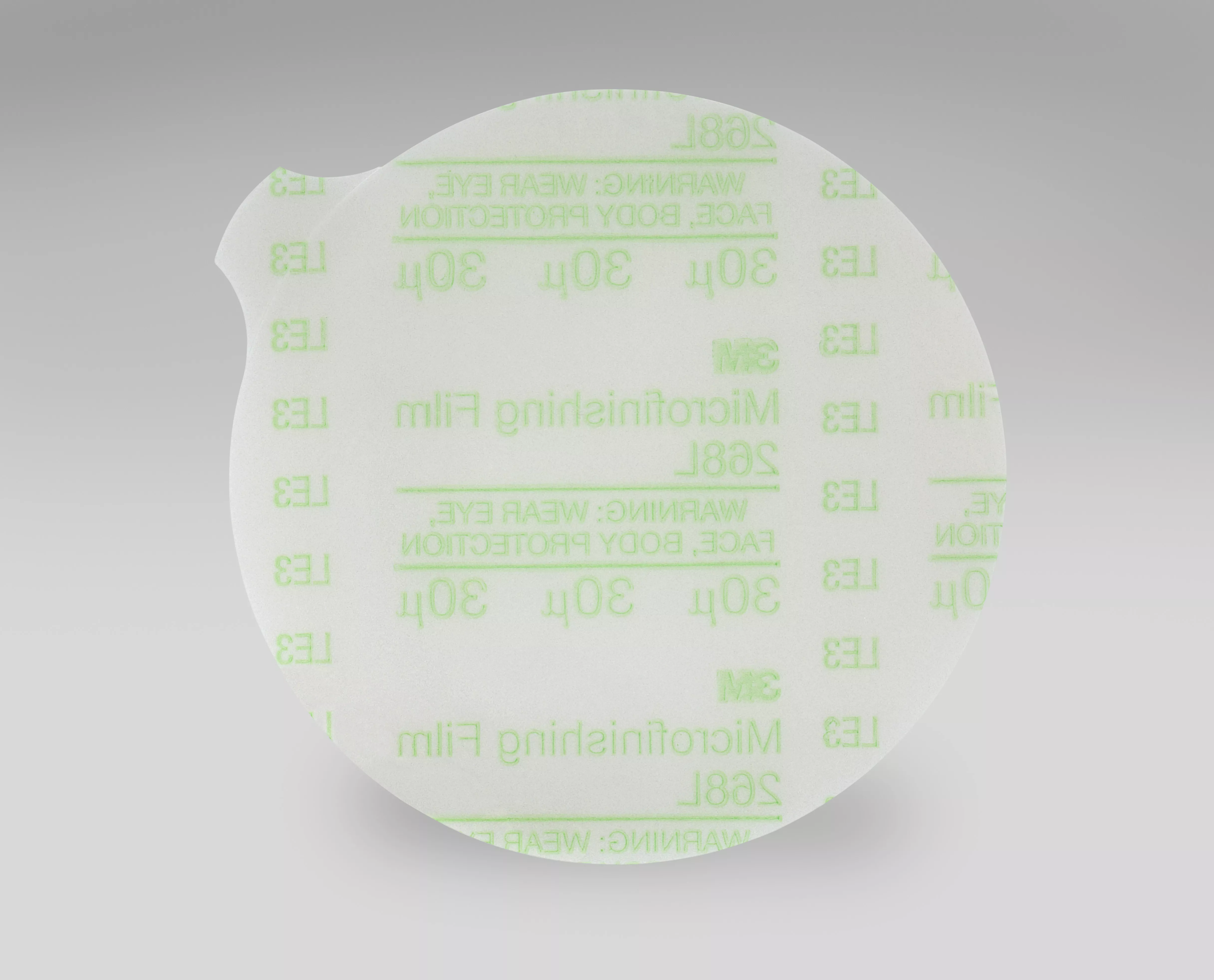

3M Microfinishing PSA Film Disc Roll 366L include multiple sanding discs packaged in a roll for convenience and use in high-production environments. These discs are rated Best in the 3M Microfinishing line of film backed discs.

- Precision, micron-graded aluminum oxide abrasive offers a fast cut, long life, and uniform finish on many substrates

- Durable polyester film backing provides flexibility for consistent finishing on contoured surfaces

- Pressure sensitive adhesive backing allows quick attachment and clean removal for multi-step finishing processes

- Open coat construction provides aggressive cut and reduced loading

- Load-resistant coating prevents dust and debris from clogging the disc

- Adhesive backing for easy attachment

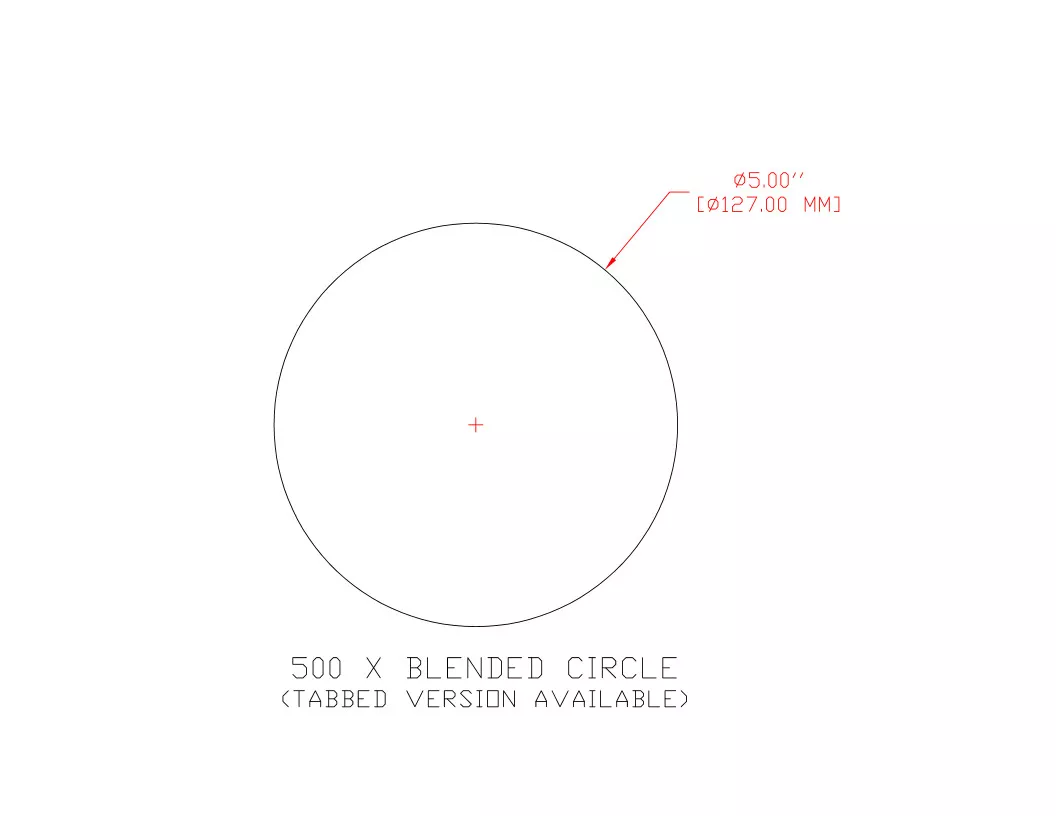

Product Dimensions |

Imperial | Metric |

| Weight | 1.97534 lbs | |

|---|---|---|

| Width | 11 in | |

| Length | 14 in | |

| Height | 8 in | |

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 8.49992 lb |

|---|---|

| Length | 10.90551 in |

| Width | 10.90551 in |

| Height | 8.30709 in |

| Color | Red |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Microfinishing PSA Film Disc Roll 366L used for?

The 3M™ Microfinishing PSA Film Disc Roll 366L is designed to be used for finishing and polishing operations. It can be used on a variety of surfaces, including metals, plastics, and composites.

-

How many discs are included in each roll of the 3M™ Microfinishing PSA Film Disc Roll 366L?

Each roll of the 3M™ Microfinishing PSA Film Disc Roll includes a total of 125 discs. There are four rolls in each case.

-

Is the disc roll easy to use with my equipment?

Yes! The PSA (Pressure Sensitive Adhesive) backing makes it easy to attach and remove from your equipment. Plus, its compatibility with commonly-used tools means that you don't need any additional components or adaptors.

Sanding discs cut better and last longer when dust isn't clogging the cutting surface of the abrasives. Open coat construction means the abrasive grains are placed with space between them to help evacuate sawdust and other sanding debris and avoid clogging the cutting edge of the grains. The load-resistant coating also allows the disc to continue cutting even when sanding softwoods, paints, and other materials that would, otherwise, clog the disc and hinder sanding ability. Additionally, the open coat feature provides a more aggressive cut than a comparable closed coat abrasive of the same grade. All of this adds up to increased productivity and reduced material consumption.

The discs are designed with a premium, micron-graded aluminum oxide abrasive, which is bonded to a durable polyester film backing to produce a fast cut-rate and uniform finish on a variety of materials, including wood, solid surface composites, plastic, fiberglass, paint prep, coating and corrosion removal, primer, e-coat, metal, or where loading is an issue. An anti-load coating and open coat surface increase efficiency and product life by minimizing loading. The abrasive is resin-bonded and supports disc flexibility without sacrificing durability and reliable performance under high heat and pressure. To compliment the effective abrasive action, the polyester film backing flexes to help achieve a consistent finish over contours and offers greater tear-resistance than comparable paper products, making it ideal for high-production environments. And the pressure sensitive adhesive (PSA) provides easy attachment, holds the disc securely in place during use, and removes cleanly from the backup pad (sold separately).

Designed for use with orbital and random orbital sanders, this disc comes in a range of micron grades and dust free option for complete multi-step sanding and finishing.

The 3M™ sanding discs come in a variety of forms to fit various power tools and disc pads. These high-quality abrasive products come ready to use with a pressure sensitive adhesive coating on the backside so they conveniently press on to a backup pad or hand pad, and remove cleanly, leaving an uncontaminated surface for the next sheet or disc.