| SKU | 7010309547 |

|---|---|

| Legacy SKU | 61500184793 |

| UPC | 00048011327433 |

| Product Number | SE-DR |

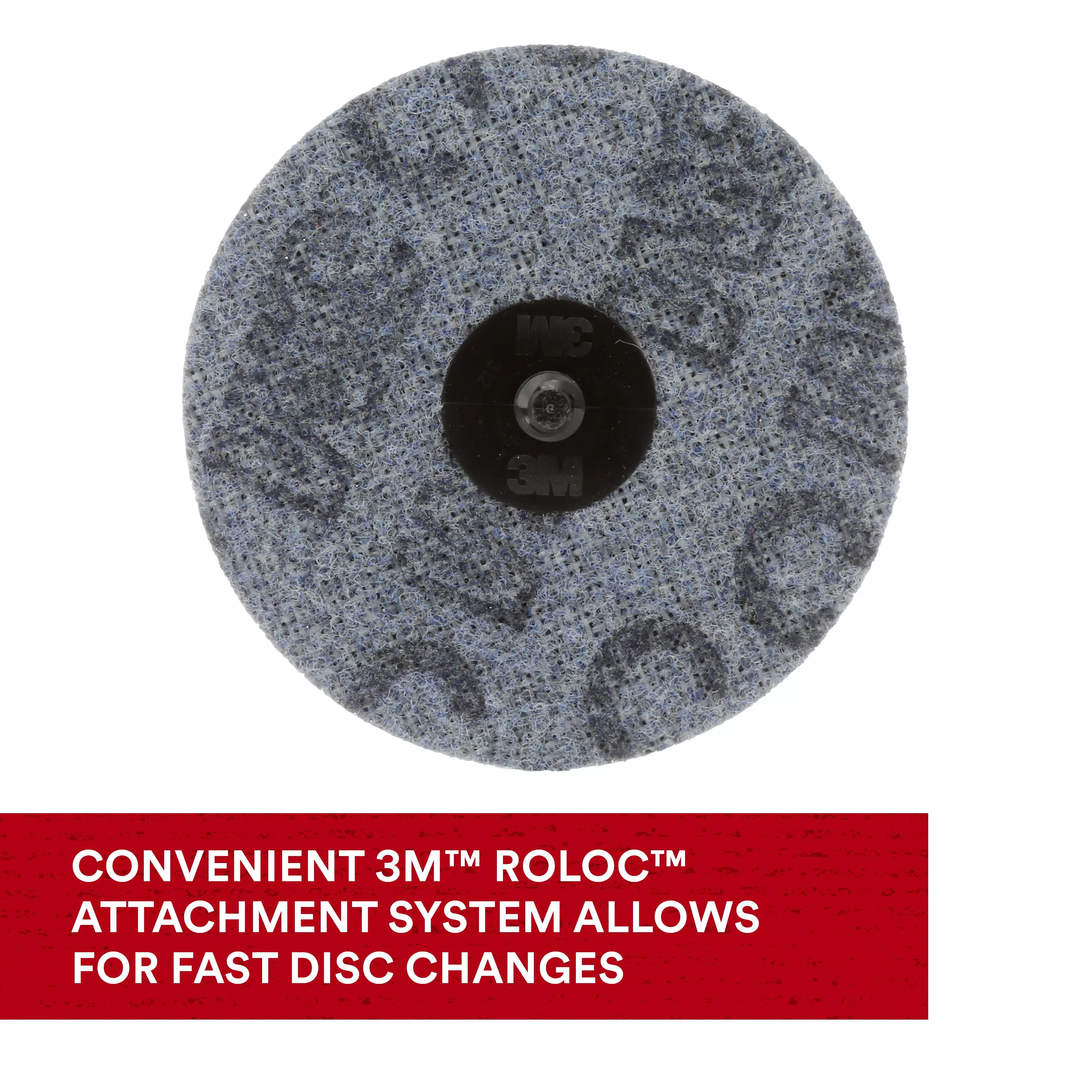

Scotch-Brite Roloc SE Surface Conditioning Disc combines a coarse, non-woven disc to perform heavy-duty deburring and finishing with the efficiency of the 3M Roloc quick-change attachment system. Heavy-duty non-woven fiber construction conforms well to help preserve irregular or contoured surfaces and Roloc backing supports the disc to allow for aggressive cutting.

- BUILT FOR HEAVY USE: Extra cut and longer life for blending, deburring, finishing, grinding, radiusing and refining

- BUILT FOR DURABILITY: Delivers a fast, aggressive cut with excellent edge durability

- WORKS ON A RANGE OF METALS: Great for use on carbon steel, and suitable for aluminum and stainless steel

- QUICK AND EASY ATTACHMENT: Convenient 3M™ Roloc™ attachment system allows for fast disc changes

- FIND YOUR FINISH: Available in a range of grades to help you achieve the finish you need

- POWERED BY ALUMINUM OXIDE: Take advantage of aluminum oxide with its high cut-rate, hardness and strength

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 3 in | 76.2 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 4.08076 lb |

|---|---|

| Length | 11.8 in |

| Width | 11.8 in |

| Height | 7.1 in |

| Color | Brown |

|---|---|

| Maximum Speed | 18,000 rpm |

PRODUCT FAQ

-

What is the size of the Scotch-Brite™ Roloc™ SE Surface Conditioning Low Stretch Disc, SE-DA, A/O Coarse, TR?

The discs are 3 inches in diameter.

-

How many pieces come in a case of Scotch-Brite™ Roloc™ SE Surface Conditioning Low Stretch Disc, SE-DA, A/O Coarse, TR?

Each case has 100 discs.

-

Can you tell me more about the material used to make this disc and what it can be used for?

The Scotch-Brite™ Roloc™ SE Surface Conditioning Low-Stretch Discs use aluminum oxide abrasive mineral. They are designed for light finishing and deburring on a variety of metals. Its non-woven fiber design resists loading or clogging and adapts well to contours for an excellent finish. These discs also have a convenient quick-change attachment system which makes assembly and disassembly fast and easy without any tools needed.

Scotch-Brite™ SE Surface Conditioning Low Stretch Disc is made of resin-reinforced non-woven fiber, which prevents under-cutting or gouging of the workpiece and resists loading. This disc is designed to have high initial and extended rates of cut while maintaining superior edge durability.

3M Conditioning Products3M conditioning products, including the Scotch-Brite™ SE Surface Conditioning Low Stretch Disc, have a woven fabric (scrim) embedded in the nylon structure to provide additional strength and durability for edge work, deburring, and efficient blending of all metal types. The non-woven material combined with abrasive grain is an ideal way to add a great finish or remove burrs.

Aluminum Oxide MineralScotch-Brite™ Roloc™ SE Surface Conditioning Low Stretch Disc is interspersed with aluminum oxide, a tough and durable abrasive that self fractures to expose fresh cutting edges in use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

3M™ Roloc™ AttachmentScotch-Brite™ Roloc™ SE Surface Conditioning Low Stretch Disc features a Roloc™ attachment, which allows the disc to attach to a 3M™ Roloc™ backup pad (sold separately). The backup pad then attaches to the power tool. With a simple ½ turn, operators can secure the disc to the backup pad and remove it again. The Roloc™ attachment system was designed to help expedite tool attachment.

The Many Benefits of Scotch-Brite™ AbrasivesScotch-Brite™ industrial abrasives are unique due to their nonwoven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products may enhance productivity while reducing the need for cleaning chemicals and wire brushes. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.