| SKU | 7000136526 |

|---|---|

| Legacy SKU | 61500152212 |

| UPC | 00048011276762 |

| Product Number | SC-DH |

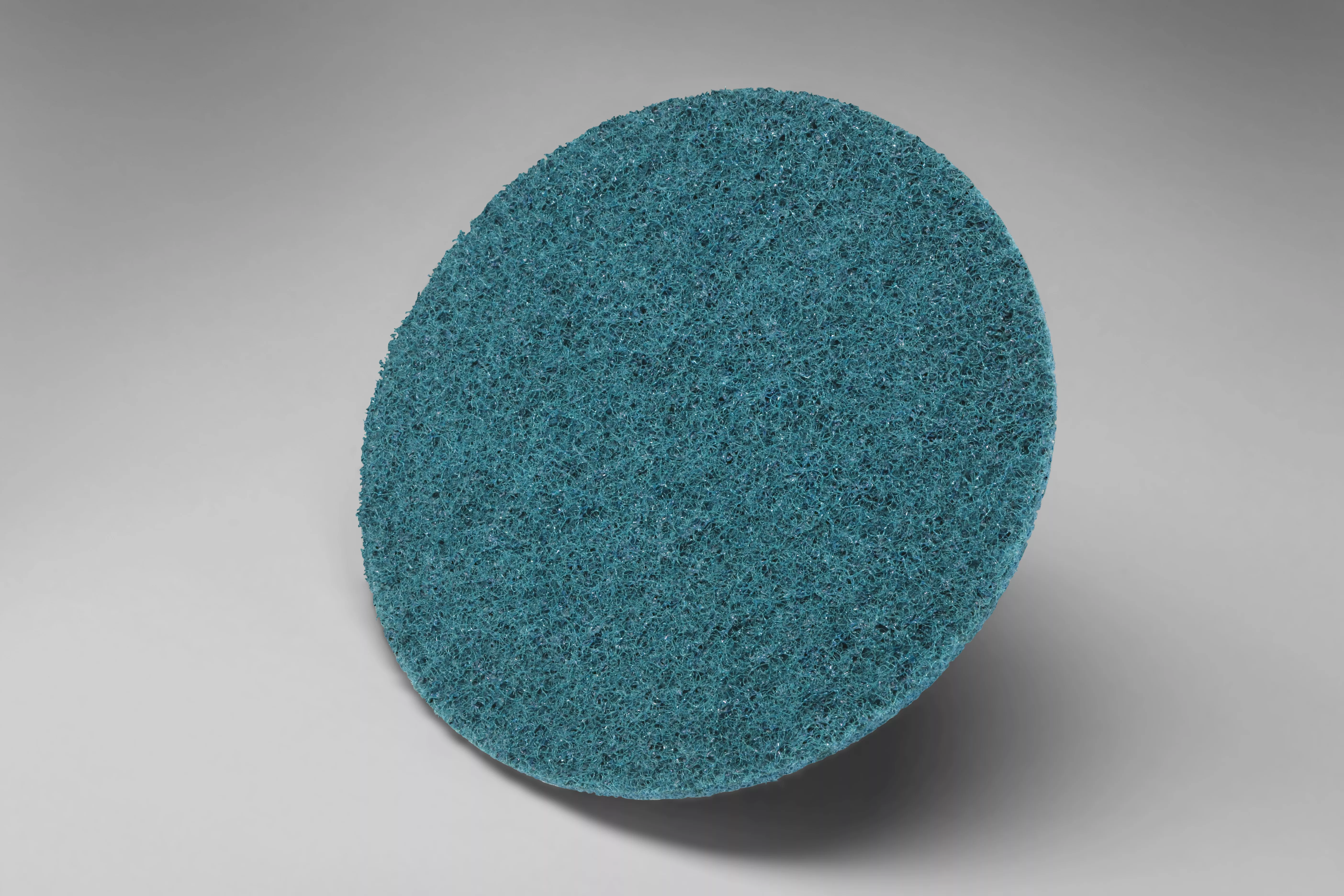

Scotch-Brite Surface Conditioning Disc comes in a wide variety of grades and sizes and is an ideal first-step for cleaning, blending, deburring, and finishing. Durable, non-woven fiber construction conforms well on irregular or contoured surfaces without undercutting or damaging the base material.

- FAST, CONSISTENT SURFACE PREP – Aluminum oxide mineral produces a high cut-rate

- MULTIPLE APPLICATIONS – Great for cleaning, finishing, blending, light deburring, rust removal and weld cleaning

- REDUCED LOADING – Open web material runs cool and reduces loading for prolonged operation

- HIGHLY CONFORMABLE – Nonwoven abrasive web conditions surface without gouging or damaging the base material

- EASY TOOL ATTACHMENT – Hook-and-loop attachment system enables fast disc change-outs for multi-step processes

- MULTI-TOOL VERSATILITY – Use with right angle and random orbital tools

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 0.585 lb |

|---|---|

| Length | 6 in |

| Width | 6 in |

| Height | 4 in |

| Color | Teal |

|---|---|

| Maximum Speed | 10,000 rpm |

PRODUCT FAQ

-

What is the size of Scotch-Brite™ Surface Conditioning Disc, SC-DH, A/O Very Fine?

The size of 3M's Scotch-Brite™ Surface Conditioning Disc, SC-DH, A/O Very Fine is 5 in x NH.

-

What does "NH" mean in the product description?

"NH" means no holes. This term is used when there are no pre-punched holes on the disc for dust collection purposes.

-

How many pieces come in a case if I order this product?

If you order this product, it comes with 10 pieces per case.

-

What surfaces can be conditioned using Scotch-Brite™ Surface Conditioning Discs of A/O very fine grade?

You can use these discs to condition and prepare different types of metals such as aluminum alloys, stainless steel and carbon steel etc., before welding or painting; also suitable for cleaning rusted components.

-

Are all materials found on this kind of surface conditioning disc non-woven abrasives?

. Yes! All materials used on our abrasive discs belong to non-woven category which comprise synthetic fibers that are bonded together through special treatment process.

Scotch-Brite Surface Conditioning Discs are an ideal first step for cleaning, blending, deburring and finishing on all types of metals. These 5” surface conditioning discs are built with durable, conformable nonwoven fibers that work great on irregular or contoured metal surfaces without undercutting or damaging the base material.

Very fine grit aluminum oxide mineral is evenly distributed within the nonwoven fiber to deliver a consistent cut during rust removal, weld cleaning, deburring and other metalworking surface prep. Combining abrasive mineral with the fibers results in a deburring disc that delivers consistent results over the life of the product.

The 3M hook-and-loop attachment on the back side of the surface conditioning disc makes it easy to attach and change-out discs in multi-step metal surface prep processes. Simply attach the surface conditioning disc to a hook-and-loop backup pad on either a right angle grinder or random orbital sander and run the tool at a maximum of 13,000 rpm.

- Great for cleaning, blending, deburring and finishing on all types of metals

- Durable, conformable nonwoven fibers work great on irregular or contoured metal surfaces without undercutting or damaging the base material

- Very fine grit aluminum oxide mineral is evenly distributed within the nonwoven fiber to deliver a consistent cut during rust removal, weld cleaning, deburring and other metalworking surface prep

- Combining abrasive mineral with the fibers results in a deburring disc that delivers consistent results over the life of the product

- 3M hook-and-loop attachment on the back side of the surface conditioning disc makes it easy to attach and change-out discs in multi-step metal surface prep processes

- Simply attach the surface conditioning disc to a hook-and-loop backup pad on either a right angle grinder or random orbital sander and run the tool at a maximum of 13,000 rpm