| SKU | 7000136522 |

|---|---|

| Legacy SKU | 61500152162 |

| UPC | 00048011276717 |

| Product Number | SC-DH |

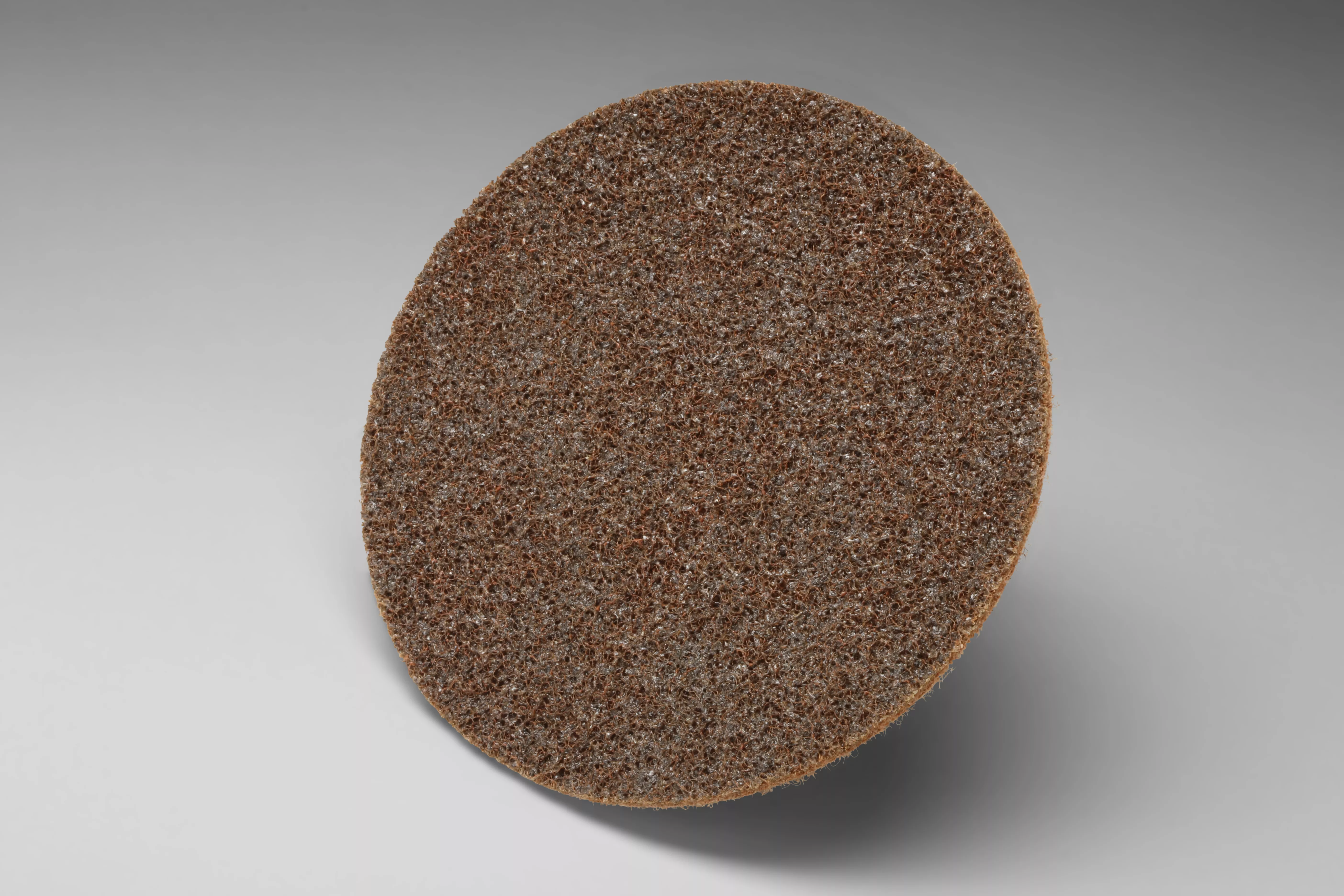

Scotch-Brite Surface Conditioning Disc comes in a wide variety of grades and sizes and is an ideal first-step for cleaning, blending, deburring, and finishing. Durable, non-woven fiber construction conforms well on irregular or contoured surfaces without undercutting or damaging the base material.

- GREAT FOR LOW-MEDIUM PRESSURE: Built for consistency in blending, cleaning, deburring, finishing, grinding, polishing, radiusing, refining and surface preparation

- CONFORMABLE NONWOVEN WEB: Springy nonwoven fibers resist loading and conform to irregular or contoured surfaces

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: Hook and loop backing makes for easy disc attachment, removal and re-attachment

- CHOOSE YOUR MINERAL: Super Fine grade is powered by super-sharp silicon carbide that excels in low-pressure and fine finishing applications, while all other grades feature harder and more durable aluminum oxide

- AVAILABLE IN A RANGE OF GRADES: Choose from Super Fine (SFN), Very Fine (VFN), Medium (MED) and Coarse (CRS) to fit your application needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 4-1/2 in | 114.3 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 0.64992 lb |

|---|---|

| Length | 5.98425 in |

| Width | 5.98425 in |

| Height | 4.01575 in |

| Color | Brown |

|---|---|

| Maximum Speed | 13,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Surface Conditioning Disc, SC-DH, A/O Coarse used for?

The SC-DH disc is a versatile product designed to provide fast and aggressive stock removal on various surfaces, including metals, plastics, and composites.

-

What kind of attachment options are available for these discs?

Our 4-1/2 inch x NH discs have a hook-and-loop attachment system that makes them easy to attach and remove from your tools. If you require other attachments such as 5/8-11 internal threads or a Roloc™ quick-change attachment system we offer those as well.

-

How long do these discs last?

The life expectancy of our Scotch-Brite™ Surface Conditioning Discs depend on varying factors such metal hardness , contact pressure during use etc., but generally they can be expected to outlast competing products.

-

Is the media silicon carbide or aluminum oxide abrasive?

Our A/O coarse grit surface conditioning discs contain premium grade aluminum oxide abrasive.

Scotch-Brite™ Surface Conditioning Disc

The Scotch-Brite™ Surface Conditioning Disc uses aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Scotch-Brite™ Industrial Abrasives

Scotch-Brite™ industrial abrasives are unique surface conditioning products with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.