| SKU | 7000121100 |

|---|---|

| Legacy SKU | 61500292232 |

| UPC | 00048011603063 |

| Product Number | XP-WL |

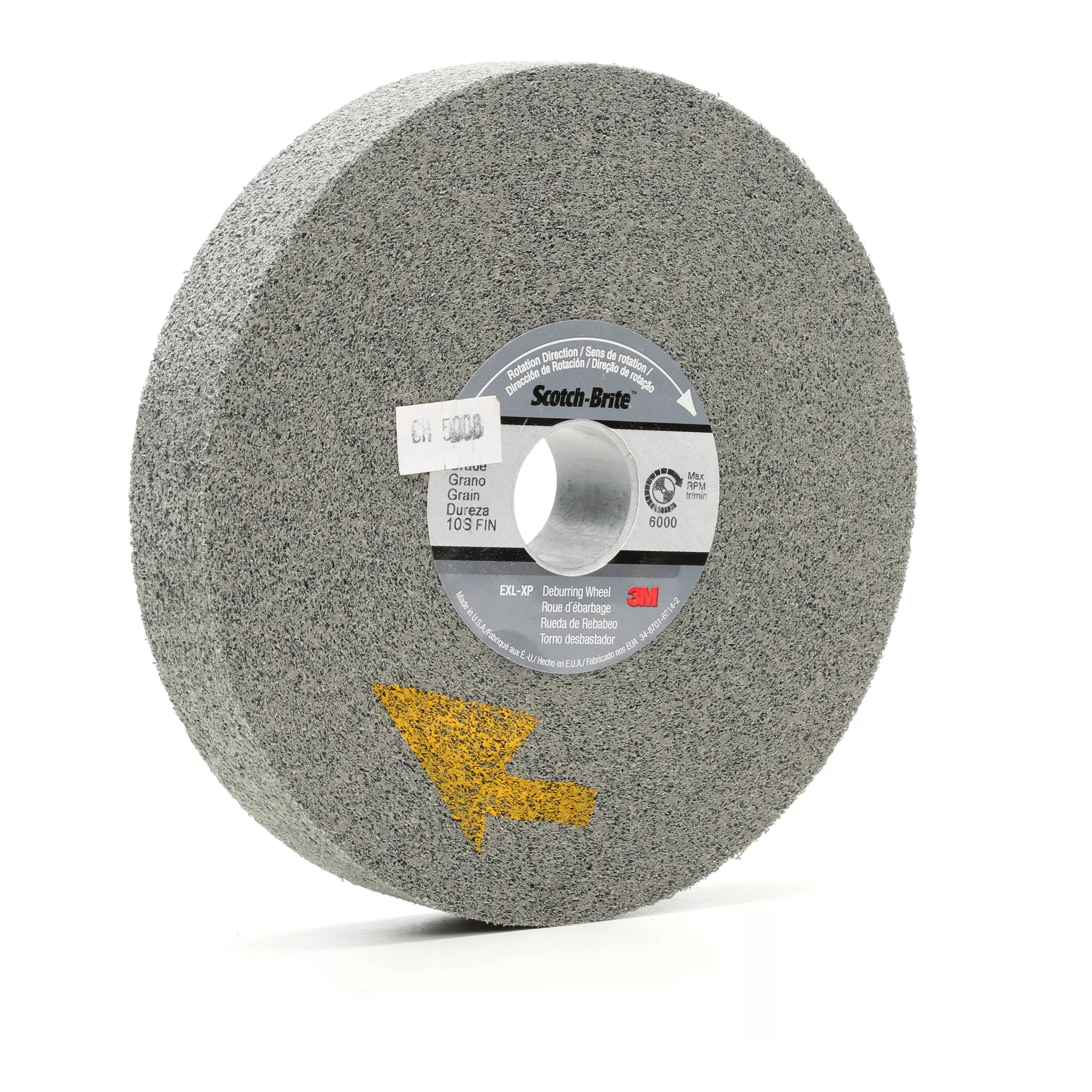

The Scotch-Brite EXL-XP Deburring Wheel offers superior durability and edge retention for tackling tough burrs and sharp edges on all types of metals, composites and glass. The EXL-XP wheel is designed to deliver a high cut rate and smooth running over the life of the wheel.

- Longest lasting wheel in the EXL line offers high cut rate and smooth running for demanding deburring, polishing and finishing

- Works on all metals, composites and glass while delivering the same superior finish and consistency as Scotch-Brite™ EXL family of wheels

- Exposed mineral produces less smearing, reducing time spent cleaning and prepping surfaces

- Minimizes heat build up to lessen impact on heat-sensitive materials

- New technology maintains wheel conformability, offers superior edge retention and resists “chunking”

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Center Hole Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 2.73373 lb |

|---|---|

| Length | 6.88976 in |

| Width | 6.88976 in |

| Height | 4.37008 in |

| Color | Gray |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 6,000 rpm |

PRODUCT FAQ

-

Can the 3M Scotch-Brite™ EXL-XP Deburring Wheel be used on stainless steel?

Yes, it can. In fact, this wheel is designed to work well on various metals including stainless steel.

-

What is the difference between the fine and coarse grits of this deburring wheel?

The fine grit (9S) will provide a smoother finish with less material removal compared to the coarse grit.

-

How long does each wheel typically last?

This depends on many factors, such as how often it is used and what type of materials are being worked on. However, these wheels are known for their durability.

-

Do I need any special tools or equipment to use this deburring wheel?

No, you do not need any additional equipment aside from a compatible power tool like an angle grinder. It's best suited for surface preparation tasks such as cleaning up welds or removing rust spots.

The Scotch-Brite™ EXL-XP Deburring Wheel is designed to provide ultimate durability and edge retention. Its resin system and convolute construction allow the wheel to run true and consistently while keeping fresh mineral exposed to do the work. The wheel's hardness, edge retention, and consistent cut combine to help resist "chunking," so the wheel continues to run true. Smooth running and fast cutting reduce operator fatigue while wheel hardness and exposed mineral deliver long life and consistent finishing.

Scotch-Brite™ EXL-XP Deburring WheelThe Scotch-Brite™ EXL-XP Deburring Wheel is filled with fine (FIN) silicon carbide mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep. Although it breaks down faster than aluminum oxide, it produces a superior finish.

The Science of SmoothThe Scotch-Brite™ line of surface conditioning products includes a variety of non-woven synthetic fiber webs and molded wheels impregnated with abrasive minerals. These products are well-suited for cleaning, blending, deburring, finishing, and polishing, and improve surfaces without significantly changing the shape or dimension of the workpiece. Scotch-Brite™ abrasives run cool and resist loading due to their open web construction. This reduces the risk of part discoloration and warping while extending the life of the wheel. They're designed to help you achieve the surface finishes and part tolerances you desire – making your applications fast, easy, and efficient.