| SKU | 7000120774 |

|---|---|

| Legacy SKU | 61500088697 |

| UPC | 00048011163482 |

| Product Number | SC-BF |

Scotch Brite Surface Conditioning Film Backed Belt is a non-woven belt used for cleaning, finishing, blending and deburring applications. The smooth, tough, stretch-resistant nylon film backing works well with platens or when reduced friction is required.

- Great multi-purpose belt, ideal for cleaning, finishing, blending and deburring

- Nylon film backing is stretch resistant for close, ongoing cutting action

- The film backed belts work great on stroke sanders when reduced friction on the back of the belt is desired

- Gaps between nylon fibers allow debris to escape, helping to reduce loading

- Fibers break down gradually to reveal fresh mineral, producing consistent cuts

- Available in a range of grades, minerals and converted forms

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 10.00017 lb |

|---|---|

| Length | 12.59843 in |

| Width | 12.48031 in |

| Height | 9.29134 in |

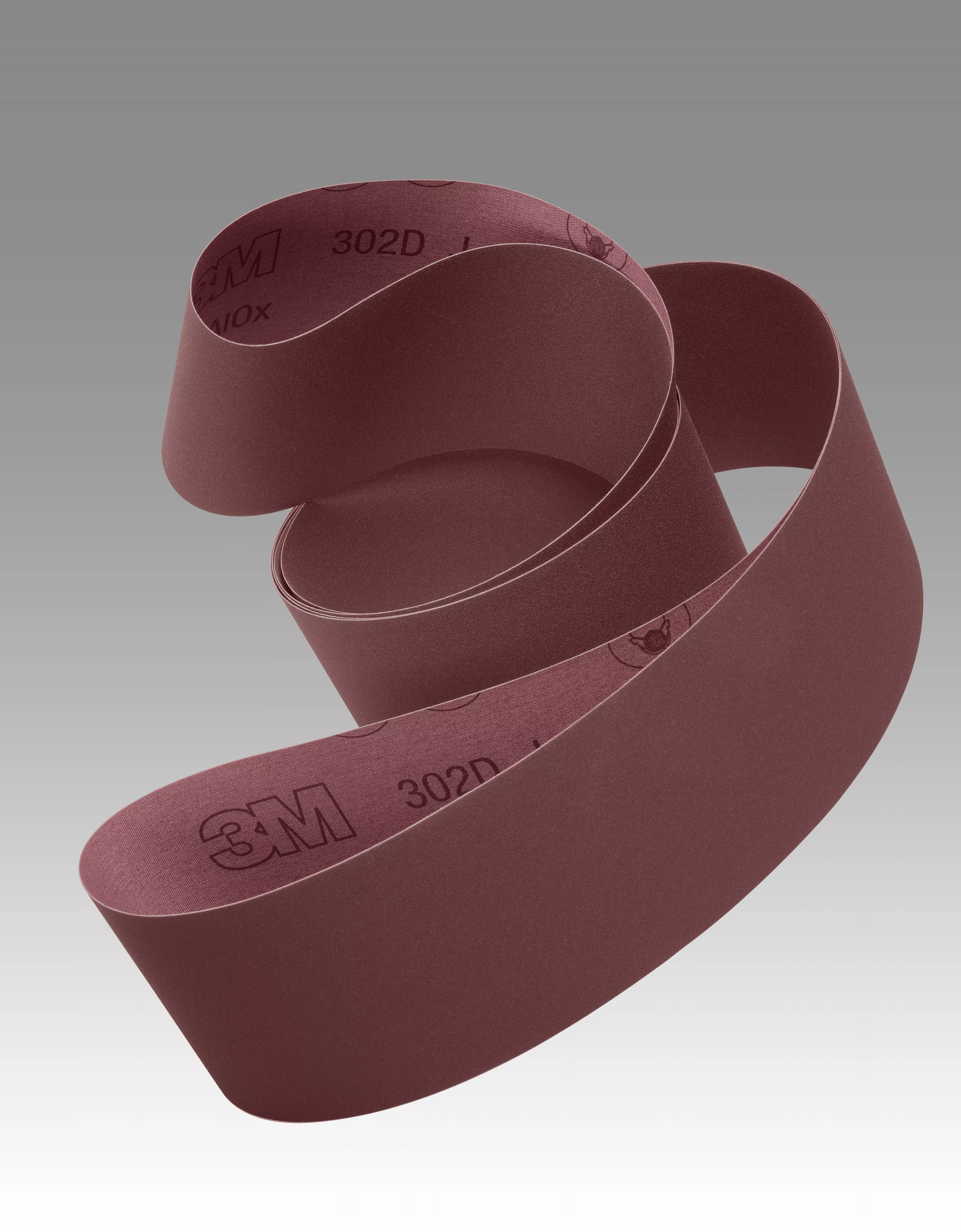

| Color | Maroon |

|---|---|

| Maximum Speed | 6,500 ft/min |

PRODUCT FAQ

-

What is the dimension of 3M's Scotch-Brite™ Surface Conditioning Film Backed Belt, SC-BF, A/O Medium?

The dimension of this belt is 6 in x 306 in.

-

What quantity do we get per case for Scotch-Brite™ Surface Conditioning Film Backed Belt, SC-BF, A/O Medium?

You get one belt per case.

-

Can you tell me more about the backside material of this belt?

This surface conditioning film backed belt uses a strong polyester film as backing material to provide both flexibility and long-lasting durability.

-

Is it possible to use water with alcohol-based detergents while cleaning during finishing jobs using these belts?

Yes. These belts can be used wet or dry on various metals without losing their quality

-

.Can I return my order if I am not satisfied with the product?

.Yes! Our main priority is customer satisfaction so you can easily return any unused items within thirty days from when they were delivered to receive a refund.

Multi-Purpose Belt Great for Tackling Multiple Applications

When working on flat parts, it's important to have a belt that can abrade the surface closely. The Scotch Brite™ Surface Conditioning Film Backed Belt was designed specifically for this purpose. The nylon-backed belt has a reduced friction backing and is low stretch, making it less likely to yield or stretch when run. This belt backing works well when the standard scrim belts stretch and fall off the machine.

Versatile Belt Options

One of the best benefits of the Scotch Brite™ Surface Conditioning Film Backed Belt is its versatility. It comes in a range of minerals, grades, and converted forms, so you're likely to find the right match for your application. You can choose between silicon carbide or aluminum oxide mineral. Aluminum oxide is available in coarse (CRS), very fine (VFN), and medium (MED) grades. Silicon carbide is available in super fine (SFN), very fine (VFN), and medium (MED) grades. Aluminum oxide is a synthetic mineral known for its sharp cut, durability, and long life. Silicon carbide tends to break down faster than aluminum oxide but will also produce a finer finish.

The Many Benefits of Scotch Brite™ Belts

The Scotch Brite™ Surface Conditioning Film Backed Belt is available in narrow, wide, and standard sizes and is commonly run on a belt sander. Narrow belts are a good match for workpieces with narrow areas and nooks and crannies, like lobes on a crankshaft or camshaft. Conversely, wide belts are a good match for larger workpieces like stamped parts, sheet metal parts, or dies. Regardless of the belt chosen, operators can rely on consistent performance, which is what they've come to expect from Scotch-Brite™ abrasives. Nonwoven technology makes Scotch-Brite™ industrial abrasives and belts unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web.

The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for fast cut, long life, and consistent results – part after part.