| SKU | 7100170806 |

|---|---|

| Legacy SKU | 61500401106 |

| UPC | 00638060053874 |

| Product Number | SC-BF |

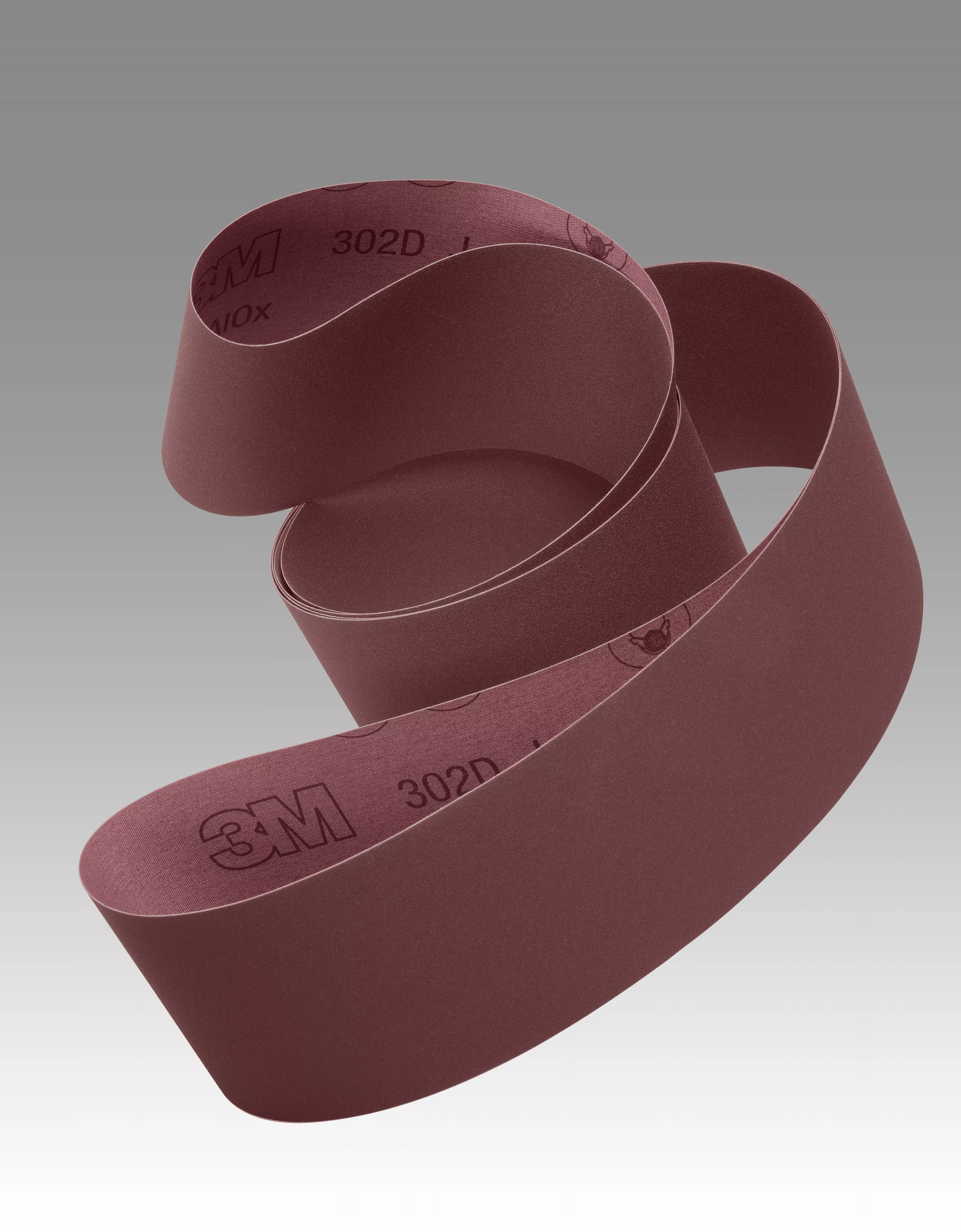

Scotch Brite SC Surface Conditioning Film Backed Belt is a nonwoven belt used for cleaning, finishing, blending and deburring applications. The smooth, tough, stretch-resistant nylon film backing works well with platens or when reduced friction is required.

- MULTI-PURPOSE VERSATILITY: Ideal belt for cleaning, finishing, blending, and deburring tasks

- STRETCH RESISTANCE: Nylon film backing ensures close, continuous cutting action

- REDUCED FRICTION: Film-backed belts are ideal for stroke sanders when lower friction on the back of the belt is needed

- REDUCED LOADING: Gaps between nylon fibers allow debris to escape, minimizing buildup

- CONSISTENT CUTTING: Gradual breakdown of fibers exposes fresh mineral, ensuring uniform cuts

- VERSATILE OPTIONS: Offered in a range of grades, minerals, and converted forms to suit various needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 6.861 lb |

|---|---|

| Length | 14.3748 in |

| Width | 14.3748 in |

| Height | 21 in |

PRODUCT FAQ

-

What is the size of the 3M Scotch-Brite Surface Conditioning Film Backed Belt, 18 in x 85 in, A VFN, 1 ea/Case?

The size of the belt is 18 inches by 85 inches.

-

What does "VFN" mean?

"VFN" stands for very fine grade abrasive.

-

How many belts come per case?

There is one belt included per case.

Enhanced Performance in Fine Finishing and Polishing Operations

The Scotch-Brite™ Finishing Film Backed Belt is designed to provide consistent, high-quality finishes on stainless steel, harder aluminum alloys, and carbon steel. This belt features a very fine grade aluminum oxide abrasive that produces excellent results in coating removal, whitewood defuzzing, scuffing on laminate, and many other applications. The film backing runs extra smooth and stands up to use with water or oil.

Durable Aluminum Oxide Abrasive

Aluminum oxide is a tough, durable abrasive that provides fast cut-rate and long life. It is widely used in grinding, sanding, and finishing applications.

Industrial Applications

- Restaurant/Food Service equipment (Dairy and Pharmaceutical) — Finishing

- Fabricated metal — Finishing

- Aerospace — Blending, finishing, and coating removal on composites and metals. Scuffing composites and metals for recoating

- Athletic equipment — Ski tuning, wax application, and ski manufacturing, scuffing prior to lacquer

- Furniture manufacturing — White wood defuzzing, sealer sanding/scuffing

- Plastic/Wood laminates — Deburring and finishing

- Jewelry — Fine satin finishing

The Scotch-Brite™ Advantage

Scotch-Brite™ industrial abrasives are unique due to their nonwoven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece. This reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite™ abrasives work fast and deliver consistent results, part after part.