| SKU | 7000042701 |

|---|---|

| Legacy SKU | 60020006395 |

| UPC | 00051111562512 |

| Product Number | 466LA |

3M Finesse-it PSA Film Disc Roll 466LA is 3Ms original microreplicated film disc frequently imitated, this technology helps remove surface imperfections from clearcoats, all without changing the surface topography.

- THE ORIGINAL microreplicated film disc for clearcoat repair

- CONSISTENT RESULTS as the abrasives reveal new cutting surfaces with each use

- SAND WITH CONFIDENCE as the micro-structured silicon carbide cuts sharply, removing imperfections without gouging

- GRADES AVAILABLE in A3, A5 and A7

Product Dimensions |

Imperial | Metric |

| Weight | 0.28528 lbs | |

|---|---|---|

| Width | 9-1/2 in | |

| Length | 11 in | |

| Height | 7 in | |

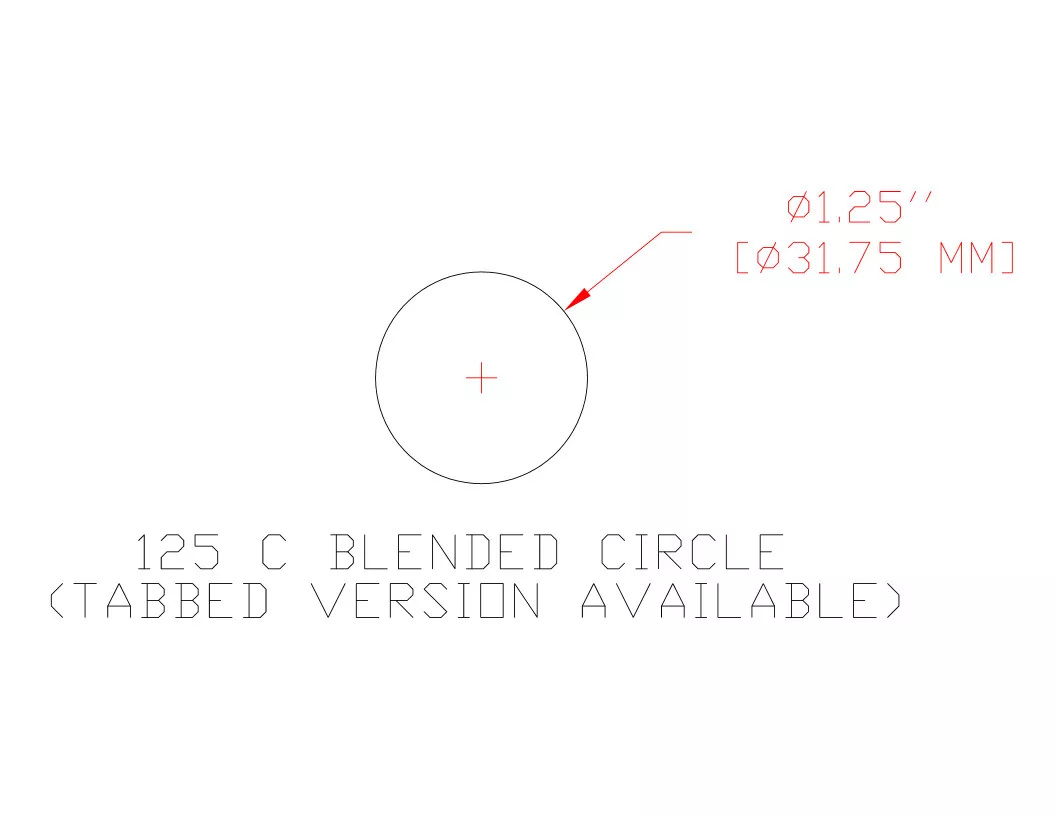

| Diameter | 1-1/4 in | 31.75 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 1.45505 lb |

|---|---|

| Length | 8.70079 in |

| Width | 8.50394 in |

| Height | 4.84252 in |

| Color | Gray |

|---|---|

| Maximum Speed | 10,000 rpm |

PRODUCT FAQ

-

What is the size of each disc in the 3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA?

Each disc in the roll measures 1-1/4 inches in diameter.

-

How many discs are included in one roll?

There are 500 discs per roll of the 3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA.

-

Is this product suitable for hand or machine applications?

The 3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA is designed for both hand and machine applications, providing versatility depending on your needs.

-

Can you tell me more about the grit rating of these film discs?

The Trizact technology utilized gives it a rated A5 abrasiveness, ensuring effective material removal and generation of consistent finishes.

-

How many rolls will you receive if you order one case?

When ordering one case, there will be four rolls of the 3M™ Trizact Finesse-it Film Disc Roll

3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA is a clearcoat spot repair disc used by automotive manufacturers worldwide. It is available in three grades: A3, A5, and A7. These discs come in a convenient roll form, allowing for quick access and attachment to rotary tools or orbital sanders.

While silicon carbide breaks down faster than aluminum oxide, it produces a brighter finish. This makes it a popular choice for defect repair on clear coats, paint, and plastics. It effectively refines these surfaces without causing significant gouging or damage.

Recommended Applications Machine Sanding- Level/remove the defect using the 3M™ Elite Series Mini Orbital Sander 28737 or the 3M™ Mini Random Orbital Nib Sander 20244 and a 3M™ Trizact™ Finesse-it™ 466LA disc

- Spray the disc with water to prevent the abrasive from loading during sanding

- Sand the defect for 1 to 3 seconds, depending on its size

- Wipe the area clean with a Scotch-Brite™ High Performance Cloth

- Level/remove the defect using a 3M™ Finesse-it™ Hand Pad and a 466LA disc

- Spray the 466LA disc with water to prevent the abrasive from loading during sanding

- Sand the defect for 3 to 5 seconds, depending on its size

- Wipe the area clean with a Scotch-Brite™ High Performance Cloth

For automotive finishes, small defects can be removed using a 466LA A5 disc. It is recommended to sand in a circular motion while holding the pad flat to ensure a fine and uniform finish.

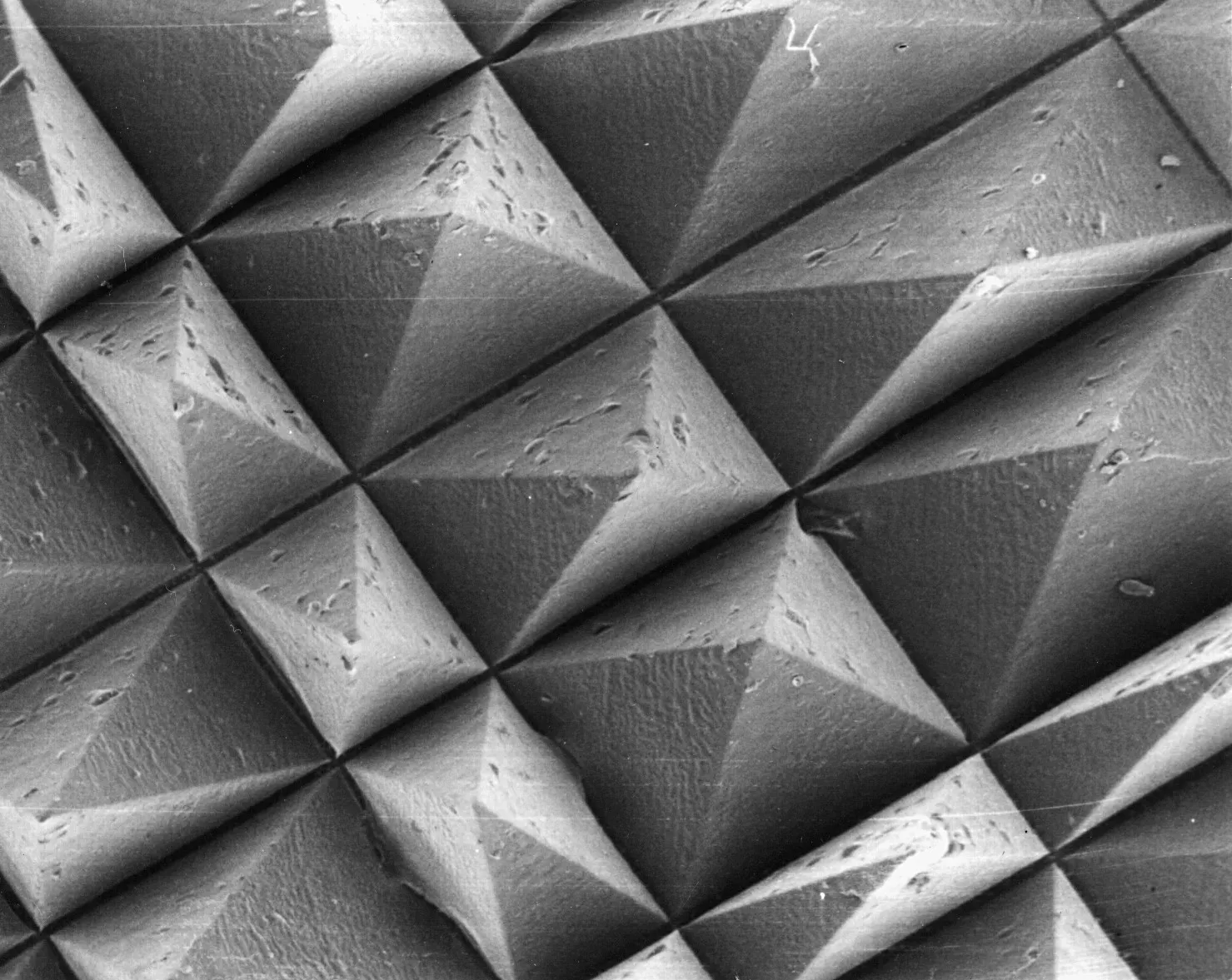

3M™ Trizact™ structured abrasives are precisely shaped engineered composites evenly distributed and bonded to an abrasive backing. These abrasives have extremely uniform structures that can take the form of various three-dimensional geometric shapes, such as pyramids, hemispheres, and cubes. This design enhances grinding performance. Unlike conventionally coated abrasives with erratically spaced mineral, Trizact™ abrasives have identical height and orientation, wearing uniformly. As they wear, fresh and sharp mineral is exposed, resulting in a consistent cut and a predictable, fine finish. This leads to fewer rejects and less rework due to out-of-spec results. The ongoing sharp cutting action reduces the need for incorporating other abrasives in the sequence, streamlining processing steps and enhancing productivity.

In addition to high-performance abrasives, 3M also utilizes microreplication technology in the manufacture of various products, including overhead projector lenses, reflective traffic signs, and solar optical films. This scientific approach makes your world smoother and brighter.