| SKU | 7100218844 |

|---|---|

| Legacy SKU | 70007542551 |

| UPC | 00638060405598 |

| Catalog Number | LSE-160WF |

| Product Number | LSE-160WF |

3M VHB Tape LSE-160WF is a double-sided tape comprised of a multi-purpose modified acrylic adhesive with a conformable, foam core delivering a total thickness of 62 mil (1.6 mm) when applied that was developed specifically for LSE substrates, such as polypropylene (PP), thermoplastic elastomers (TPE), and thermoplastic olefins (TPO). It creates a long-lasting, high-strength bond without the use of primer or promoter while offering the versatility to join dissimilar and delicate materials that would typicall

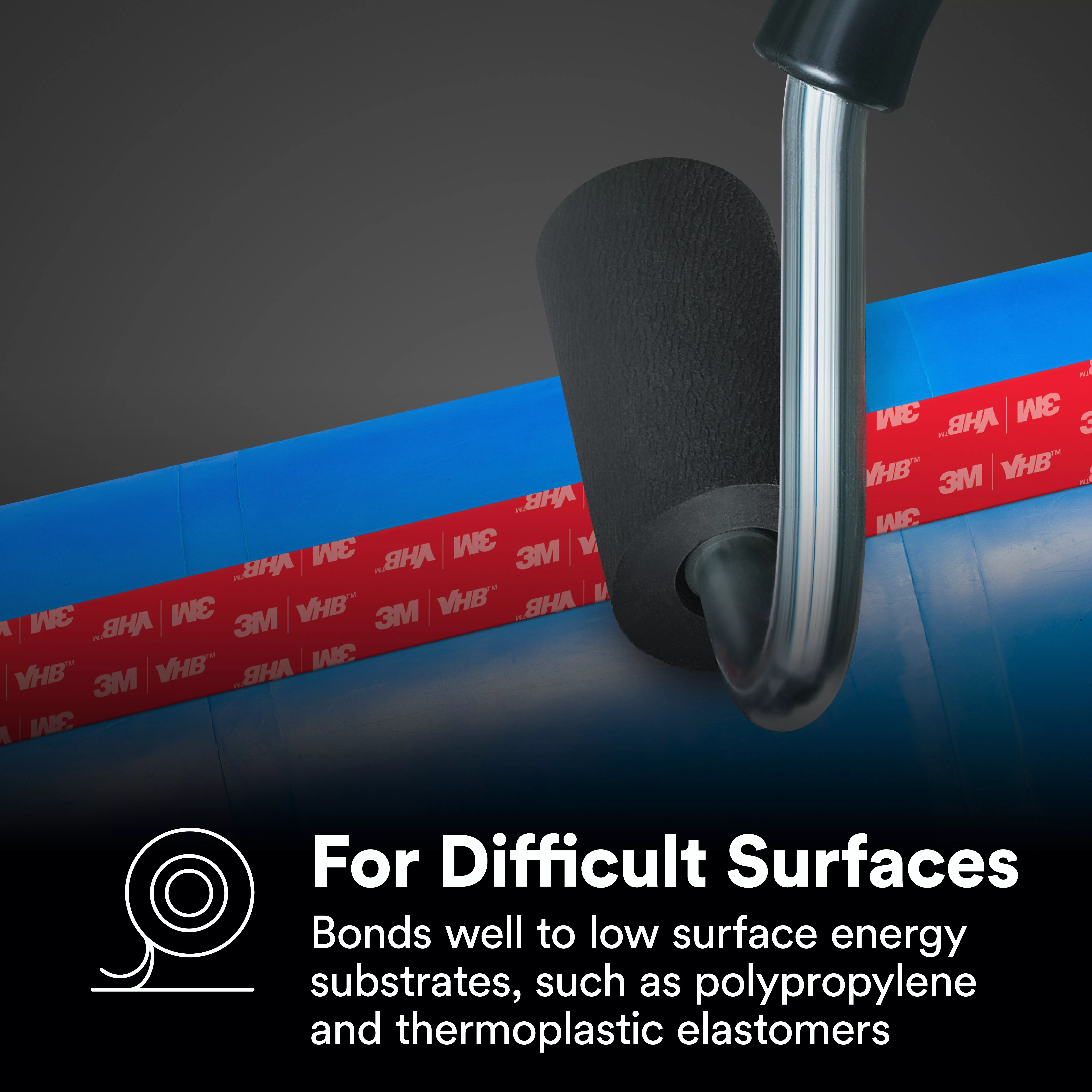

- FOR DIFFICULT SURFACES: Bonds well to low surface energy substrates, such as polypropylene (PP), thermoplastic elastomers (TPE), and thermoplastic olefins (TPO)

- LOW-TEMPERATURE BONDING: Offers high initial tack at low temperatures on frost-free surfaces down to 32 °F (0 °C)

- NO PRIMER NEEDED: Directly bonds a wide range of plastics, streamlining the application process by eliminating the need for surface primers on many materials

- COST EFFICIENCY: Provides a fast and easy-to-use all-acrylic bonding method that eliminates additional processes and equipment — helping to lower manufacturing costs

- MULTI-MATERIAL BONDING: With a thickness of 62 mil (1.6 mm), this tape effortlessly joins non-compatible materials and delicate substrates without relying on ultrasonic welding equipment or mechanical fasteners

- BUILT TO PERFORM: Delivers high shear strength, conformability, and surface adhesion due to an acrylic foam core and multi-purpose adhesive

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 62 mil | 1.6 mm |

Shipping Dimensions |

|

| Weight | 22.52099 lb |

|---|---|

| Length | 13.9 in |

| Width | 13.9 in |

| Height | 10 in |

| Color | White |

|---|

PRODUCT FAQ

-

What is the thickness of the 3M™ VHB™ Tape LSE-160WF, White?

The tape has a thickness of 62 mil.

-

How many rolls come in one case of the 3M™ VHB™ Tape LSE-160WF, White?

Each case comes with 18 rolls.

-

What are some recommended applications for this type of tape?

This tape is great for bonding materials with low surface energy such as polypropylene and thermoplastic elastomers. It's also ideal for indoor general purpose mounting and joining applications.

The LSE Family of 3M™ VHB™ Tapes is the perfect solution for low surface energy (LSE) bonding. It offers superior bonding performance without primer on difficult to bond substrates such as PP, TPO, TPE, and composite materials. By eliminating the need for priming in your production, the LSE Series increases productivity and reduces the use of harsh chemicals in your facilities. Its excellent durability and wide range of temperature resistance ensures ultimate performance strength and reliability for in- and outdoor applications. The fast and easy to use permanent bonding method provides high strength and offers design flexibility with its viscoelasticity, making it an ideal fit for multi material bonding due to its properties on thermal expansion.

The LSE series of 3M™ VHB™ Tapes utilizes modified acrylic adhesive on both sides of a conformable, adhesive foam core. The combination of strength, conformability and adhesion makes this family one of the most capable and well-rounded 3M™ VHB™ Tapes. It offers superior bonding performance on difficult to bond substrates such as PP, TPO, TPE, and composite materials including glass filled plastics, glass and carbon reinforced or gel coated composites as well as most polyester paints without primer. It also bonds well to many MSE plastics and metals. The modified acrylic construction makes the 3M VHB Tape LSE Series resist hot, cold and cycling temperatures, UV light, moisture and solvents and seals against environmental conditions. Its performance in a wide temperature range provides a durable alternative to rivets, welds and screws. 3M VHB Tape permanently adheres one substrate to another while spreading the stress load across the entire length of the joint. This results in a strong and reliable bond that can withstand harsh environmental conditions and extreme temperatures.

Benefits of the LSE Family of 3M™ VHB™ Tapes:- Superior bonding performance without primer on difficult to bond substrates

- Increased productivity and reduced use of harsh chemicals in facilities

- Excellent durability and wide range of temperature resistance

- Fast and easy to use permanent bonding method

- Design flexibility with its viscoelasticity

- Resists hot, cold and cycling temperatures, UV light, moisture and solvents

- Provides a durable alternative to rivets, welds and screws

- Spreads stress load across the entire length of the joint for a strong and reliable bond