| SKU | 7100192104 |

|---|---|

| Legacy SKU | 61500403854 |

| UPC | 00638060058534 |

| Product Number | SL-BS |

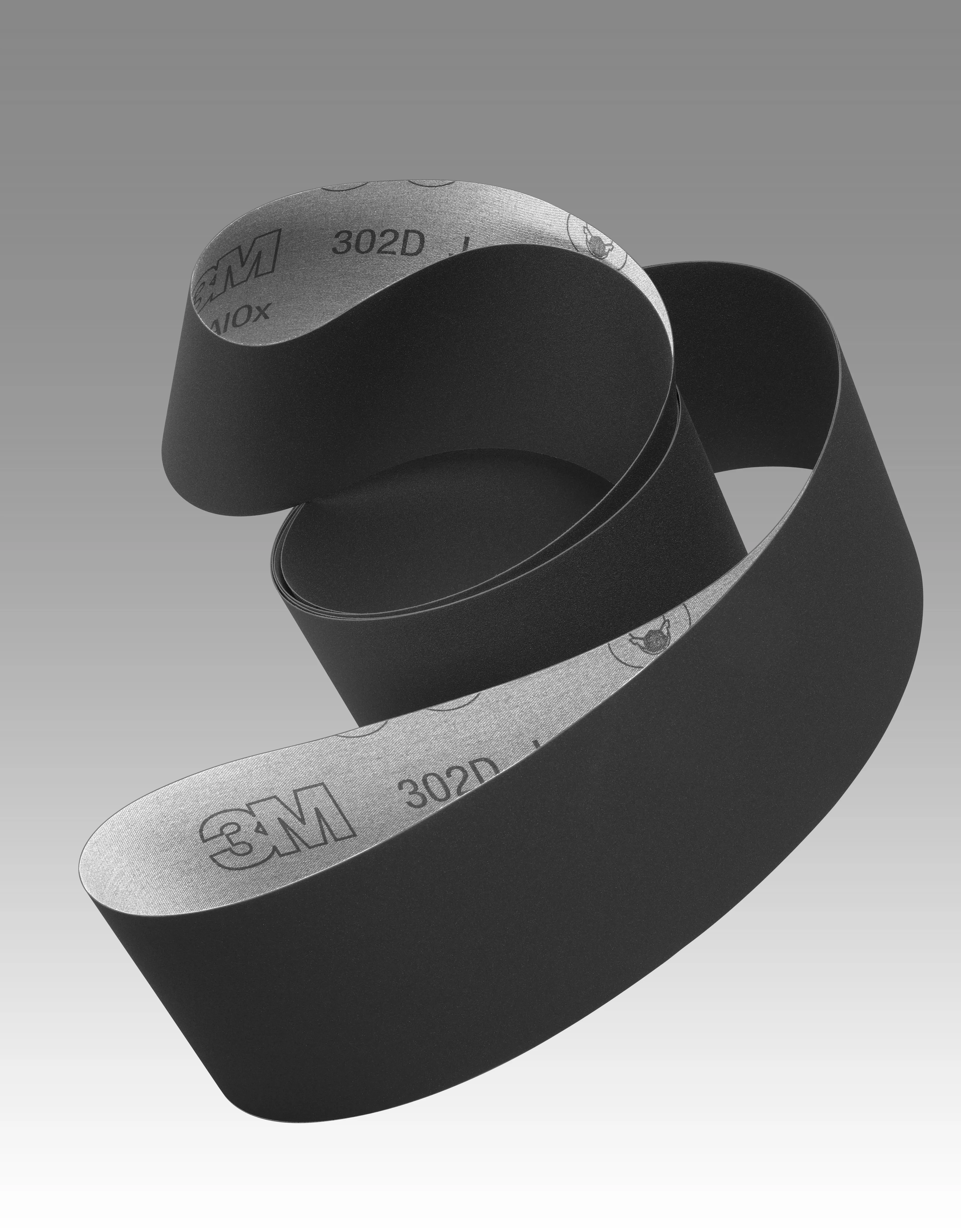

Scotch-Brite SL Surface Conditioning Belt is a durable, aggressive non-woven belt that balances flexibility with aggressive cutting action. It blends and finishes consistently, often in one step.

- Aluminum Oxide mineral, available in a range of grades, cuts sharp and leaves a fine finish

- For use on backstand and off hand equipment

- Reinforced backing and non-woven open web material provides superior flexibility for detail work, over contours and edges

- Reduced loading and heat build-up allow extended operating time and consistent surface conditioning results

- Aggressive cutting without gouging, removes surface imperfections, grindlines, mill and other marks

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 0.785 lb |

|---|---|

| Length | 8.6 in |

| Width | 8.5 in |

| Height | 6.7 in |

PRODUCT FAQ

-

What is the 3M Scotch-Brite SL Surface Conditioning Belt made of?

The 3M Scotch-Brite SL Surface Conditioning Belt is made from non-woven material and contains aluminum oxide abrasive.

-

Can the belt be used with a variety of materials?

Yes, the 3M Scotch-Brite SL Surface Conditioning Belt can be used on multiple surfaces, such as stainless steel, nickel alloys, and titanium.

-

How long can I expect the belts to last during use?

Our products are incredibly durable. They tend to provide a consistent cut-rate throughout their lives if properly maintained. However,the lifespan of your abrasives depend entirely upon application variables such as contact force with work piece or pressure settings.

-

Do these require special tools for grinders or sanders?

.: No special tools are required, although it's important to use an appropriate rigid backing plate while performing grinding tasks which helps to control heat management while providing exceptional durability under high-contact cutting pressures.

-

.: Is this product safe for heavy-duty projects?

.: Yes! The A CRS Super Duty makes it perfect for heavy deburring purposes like cleaning castings lines that need deep grooves removed with ease so you don't have any nicks in your final finish.

Scotch-Brite™ SL Surface Conditioning Belt is a surface conditioning belt that balances durability and flexibility. It is ideal for medium-duty projects on hard metals such as intermediate blending, deburring, finishing, and cleaning on stainless steel, carbon steel, titanium, and nickel alloys. All Scotch-Brite™ SL Surface Conditioning Belts use aluminum oxide mineral, but they vary in aggressiveness: Super Duty (SD), Heavy Duty (HD), Coarse (CRS), and Medium (MED).

A Responsive BeltThe reinforced backing on Scotch-Brite Surface Conditioning Belts offers good flexibility whether working on a file belt or backstand. All belts may be used for "low stretch" applications, because, while flexible, they also stay taut and firm. The belt is engineered by combining non-woven nylon fibers and mineral with resin. Mixing non-woven nylon fibers, which are springy and responsive, with mineral is an ideal way to add a great finish or remove burrs without gouging or undercutting the workpiece. A woven fabric (scrim) is also included in conditioning products, which is embedded in the nylon structure to provide additional strength and durability for edge work.

Benefits of Aluminum Oxide MineralScotch-Brite™ SL Surface Conditioning Belt uses coarse grade aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing.

Surface Conditioning BeltsSurface conditioning belts are used for rapid grinding and finishing on a variety of surfaces. Depending on the material being worked, sanding wheels and discs may clog with debris and quickly become less efficient. Belts continue to sand without clogging, because small grooves in the abrasive belt open as they go around the arc of the drive wheel. Scotch-Brite™ Surface Conditioning Belts present a swift and efficient means to achieve desired finishes.