| SKU | 7100189024 |

|---|---|

| Legacy SKU | 60440355679 |

| UPC | 00638060062425 |

| Product Number | 461F |

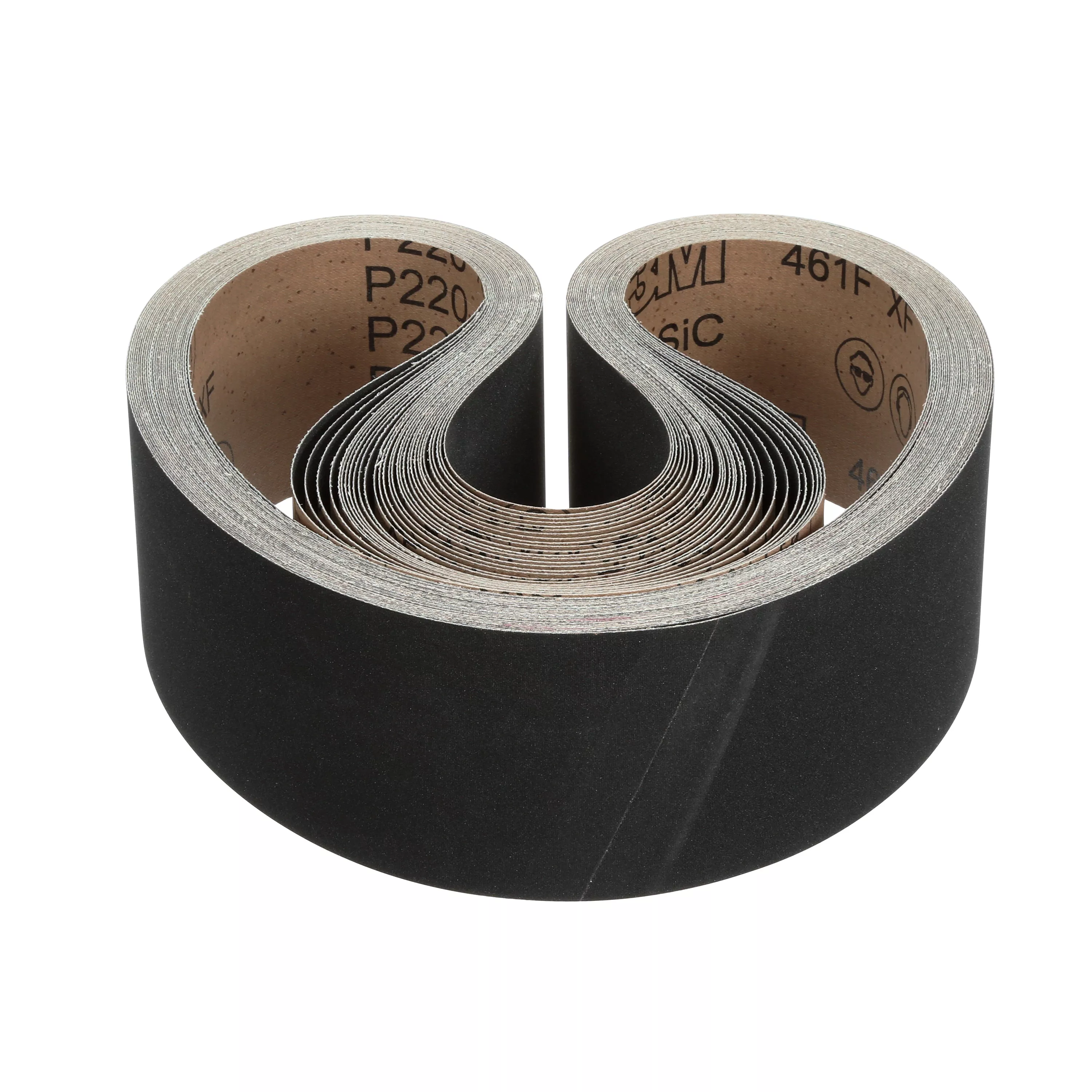

3M Cloth Belt 461F is constructed of sharp silicon carbide abrasive that fractures easily and consistently produces an excellent finish for the duration of the belt life. This resin-bonded cloth belt gives you flexibility, durability, and consistent performance for grinding, blending, deburring, and finishing on all metals.

- Sharp silicon carbide mineral cuts faster than aluminum oxide and produces a consistent finish

- Tough, water-resistant polyester backing supports wet or dry applications from heavy-duty grinding to fine finishing without tearing or nicking

- Cloth backing provides flexibility

- Heat-resistant resin coating bonds abrasive to backing for durability under pressure, heat, and water

- Use on backstands for grinding and finishing applications

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 28.733 lb |

|---|---|

| Length | 14.08976 in |

| Width | 14.00984 in |

| Height | 9.2 in |

| Color | Black |

|---|

PRODUCT FAQ

-

What type of applications is the 3M™ Cloth Belt 461F suitable for?

The 3M™ Cloth Belt 461F is designed for use in roll grinding and other general metalworking applications.

-

What does "XF-weight" mean?

"XF-weight" refers to an extra-heavy backing on the cloth belt, which can withstand high-pressure applications without tearing or breaking.

-

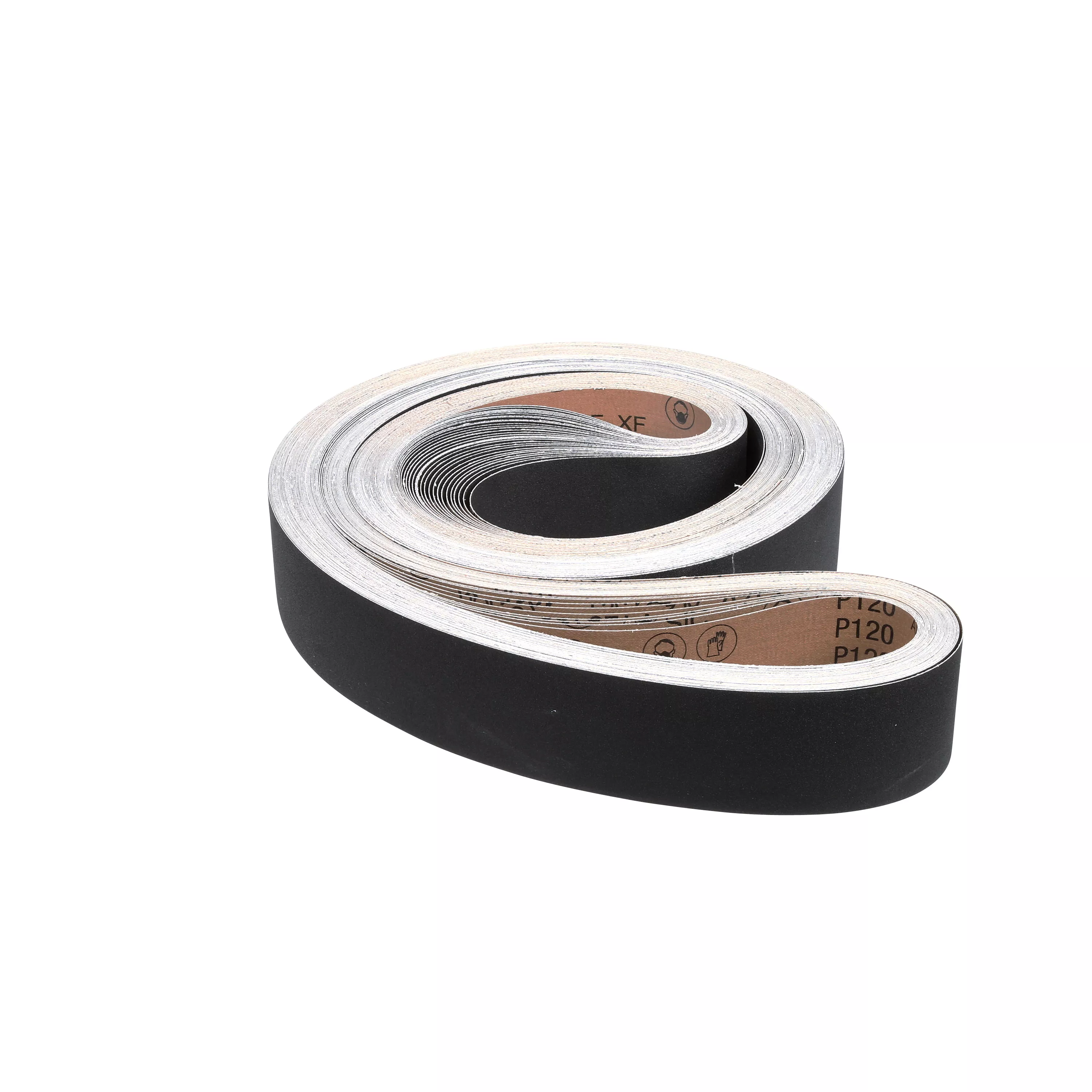

How big are the belts in a standard case of the 3M™ Cloth Belt 461F?

Each case contains fifty (50) belts that measure four inches by one hundred thirty-two inches.

-

What is Sine-Lok Precision technology and will it benefit my operations?

Sine-Lok Precision technology ensures accurate and consistent tightness of sanding belt joints. This feature helps prevent slipping during operation, reduces downtime, improves overall productivity, prolongs service life and provides precision results with excellent finishes.

-

How long do these belts last before needing replacement?

. The durability may vary depending on factors such as material hardness level, surface treatment required abrasive selection, machine set-up etc., but typically these abrasive cloth belts have a significantly longer life than conventional abrasives making them more economical even if they initially cost slightly more.

3M™ Cloth Belt 461F is a heavy-duty abrasive belt that is commonly used for coarse grade grinding on stainless steel, titanium, and glass polishing. The belt is made of heavy polyester cloth backing that provides rugged durability and tear-resistance, making it suitable for wet or dry applications. The belts come in both YF-weight polyester and XF-weight polyester.

Superior Finish Sanding with Silicon CarbideSilicon carbide is a very hard and sharp mineral that is commonly used for low-pressure applications such as paint prep and the final stages of whitewood sanding, as well as grinding applications on metal. It can also be used for glass and mirror grinding, finishing, and polishing. Although it may have a shorter life than aluminum oxide, it produces a superior finish and should be used where the best possible finish is desired.

Belt Sizes for Every ApplicationAbrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

- 3M™ Cloth Belt 461F is a heavy-duty abrasive belt that is commonly used for coarse grade grinding on stainless steel, titanium, and glass polishing.

- The belt is made of heavy polyester cloth backing that provides rugged durability and tear-resistance, making it suitable for wet or dry applications.

- The belts come in both YF-weight polyester and XF-weight polyester.

- Silicon carbide is a very hard and sharp mineral that is commonly used for low-pressure applications such as paint prep and the final stages of whitewood sanding, as well as grinding applications on metal.

- It can also be used for glass and mirror grinding, finishing, and polishing.

- Although it may have a shorter life than aluminum oxide, it produces a superior finish and should be used where the best possible finish is desired.

- Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal.

- 3M offers a broad selection of belts to fit most any industrial belt sander.

- Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets.

- Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.