| SKU | 7100150392 |

|---|---|

| Legacy SKU | 60455055842 |

| UPC | 00076308009281 |

| Catalog Number | 928 |

| Product Number | 928 |

Bondo Red Cream Hardener mixes with 2-part fillers, putties and glazes to create high-quality, long-lasting repairs. When filler and hardener are mixed, a chemical reaction occurs to create a mixture that will deliver a strong, lasting repair. This hardener is smooth and easy to mix with fillers, putties and glazes.

- Bondo cream hardener is easy to use by simply mixing with bondo fillers

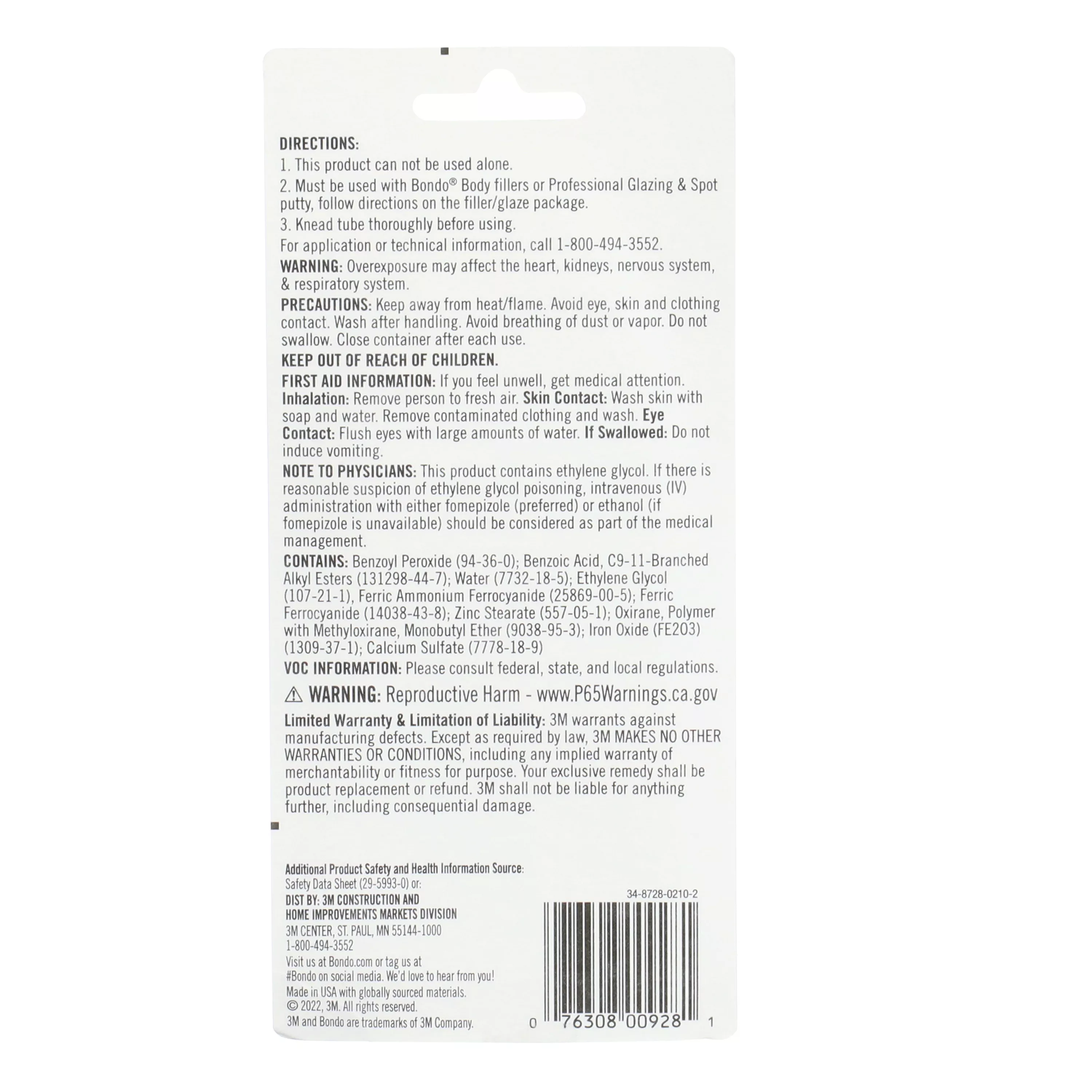

- MUST BE USED WITH Bondo® Fillers including Original, Fast-Dry, Short Strand Fiberglass Reinforced, Long Strand Fiberglass Reinforced, or Wood, and cannot be used by itself

- MIXES EASILY to produce a consistent chemical reaction for fast curing

- PACKAGED IN EASY-TO-USE squeeze tube

- TUBE AVAILABLE in multiple sizes

- WHEN FILLER AND HARDENER ARE MIXED, a chemical reaction occurs to create a mixture that will deliver a strong, long-lasting repair

Product Dimensions |

Imperial | Metric |

| Weight | 0.2 lbs | |

|---|---|---|

| Width | 1.6 in | |

| Length | 3.18701 in | |

| Height | 6.68701 in |

Shipping Dimensions |

|

| Weight | 1.6 lb |

|---|---|

| Length | 9.25 in |

| Width | 5 in |

| Height | 8.8748 in |

PRODUCT FAQ

-

Certainly! I'd be happy to help with that.

How much Bondo® Cream Hardener comes in a case of product 00928?

-

Each case contains 6 tubes of Bondo® Cream Hardener, each tube being 2.75 oz.

Is this cream hardener compatible with all types of Bondo products?

-

Yes, the Bondo® Cream Hardener 00928 is designed to work seamlessly with all varieties of Bondo fillers and putties.

What is the shelf life of this cream hardener once it's opened?

-

Once opened, the Bondo® Cream Hardener should be used within one year for optimal performance.

Can this product be stored at different temperatures without affecting its quality?

-

It is recommended to store the cream hardener between 60°F - 80°F (15°C - 27°C) for best results. Extreme temperatures may impact its effectiveness.

How long does it typically take for the cream hardener to cure after application?

-

Depending on environmental conditions like temperature and humidity, the cream hardener usually cures within minutes, allowing you to sand or paint shortly after application.

Use with 3M's Many Lines of Car Body Filler

Bondo® Red Cream Hardener is a hardening agent designed to work with all fillers, putties, and glazes. The creamy consistency of this hardener allows for easy and quick mixing. It combines ease of use with high-quality final results.

Formulated for Convenience

When mixed with a 2-part filler, a chemical reaction occurs, enabling you to make durable repairs to various surfaces such as metal, masonry, concrete, painted wood, bare wood, and drywall. The resulting repair can be sanded in just 15 minutes and painted in only 45 minutes.

Tinted Colors Help with Consistency

The cream hardeners come in tinted colors to assist in achieving consistency when mixing hardener and filler. By observing the color of the mixture, you can determine if you have added the right amount of hardener. The color of the cream hardener does not affect the curing process.

Formulated to Reduce Chances of Pinholes

This cream hardener is carefully formulated and packaged under controlled temperature conditions to ensure freshness and optimal performance. Mixing auto body filler and cream hardener is a simple task. To minimize the risk of creating pinholes, it is recommended to avoid mixing in a circular pattern, as this can introduce air into the mix. Instead, mixing should be done in a back and forth wiping or folding motion.

Use During the Fill Stage of the 3M™ Body Repair System

Even a seemingly small repair can be complex. That's why 3M's Body Repair System simplifies the entire automotive body repair process into four stages:

- Stage 1 – Prepare: This stage involves tasks such as dent pulling, paint and rust removal, and efficient masking of the repair area.

- Stage 2 – Fill: In this stage, holes are patched with reinforced filler, and the filler is smoothed and shaped before painting.

- Stage 3 – Paint: This stage includes painting the repaired area and blending and smoothing primer and paint.

- Stage 4 – Finish: The final stage focuses on achieving showroom-grade results by removing small defects, sealing, and polishing clear coats and other painted surfaces.

3M provides premium products such as abrasives, tapes, body fillers, and tools for each stage of the body repair process. This comprehensive system ensures that you can work easily, efficiently, and successfully throughout the entire repair process.