| SKU | 7100103313 |

|---|---|

| Legacy SKU | 60440299521 |

| UPC | 00051125871532 |

| Catalog Number | 87153 |

| Product Number | 87153 |

3M Cubitron II Grinding Wheel is constructed of 3M precision-shaped ceramic grain to bring you an exceptionally fast-cutting and long-lasting rigid bonded wheel for heavy weld removal and other heavy-duty grinding applications. This grinding wheel works well on almost all materials and is specially formulated for use on stainless steel, mild steel, and aerospace alloys.

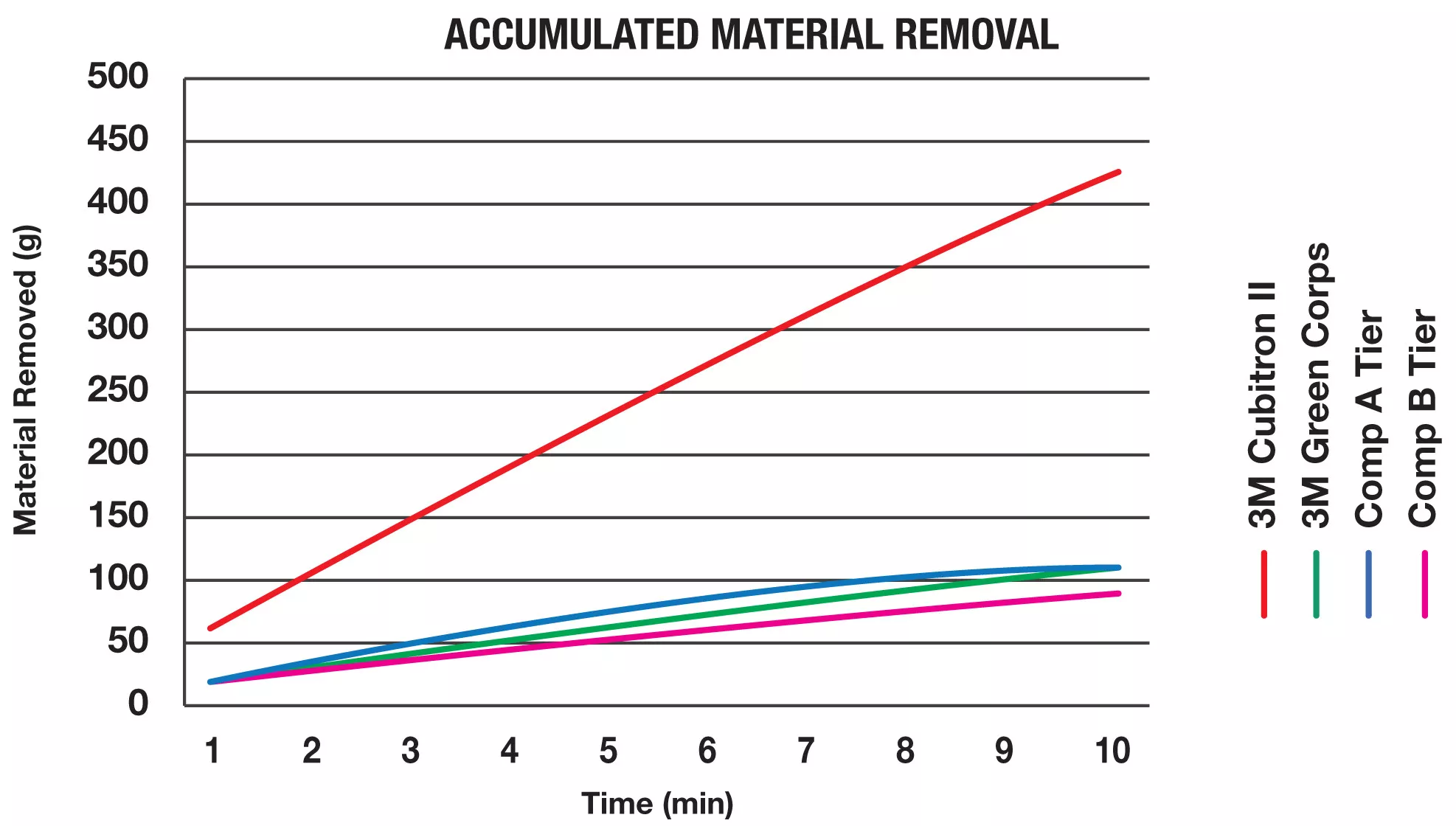

- 3M Precision-shaped grain engineered to cut faster than competitive ceramic products, offering significant productivity gains

- Triangular shaped ceramic grain wears evenly, runs cool, and optimizes mineral breakdown, for extra-long life

- Reduces changeouts and downtime in robotic and pressure-assisted applications

- Rigid, reinforced resin-bonded wheel slices through almost all materials including stainless steel, mild steel, and aerospace alloys

- Wheel must have a maximum operating speed greater than or equal to the maximum speed of the power tool used

- Must be used with ANSI-approved guard that fits the size of the wheel

Product Dimensions |

Imperial | Metric |

| Weight | 1.77913 lbs | |

|---|---|---|

| Width | 9 in | |

| Length | 1/4 in | |

| Height | 9 in | |

| Diameter | 9 in | 230 mm |

| Thickness | 1/4 in | 6 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 38.86088 lb |

|---|---|

| Length | 19.3748 in |

| Width | 10.1248 in |

| Height | 11.8748 in |

| Color | Black |

|---|---|

| Maximum Speed | 80 m/s |

PRODUCT FAQ

-

What is a Cubitron II Depressed Center Grinding Wheel?

The 3M™ Cubitron™ II Depressed Center Grinding Wheel is a premium performance grinding wheel that uses precision-shaped ceramic grain to deliver a fast, consistent cut and long life.

-

What sizes are available for the Cubitron II Depressed Center Grinding Wheel?

The 3M™ Cubitron™ II Depressed Center Grinding Wheels come in various sizes and dimensions to match your specific needs. For instance, this model comes in 9 inches x 1/4 inches x 5/8-11 (T27 Quick Change) size.

-

How many pieces come in each case of these grinding wheels?

There are a total of twenty (20) individual wheels inside one case; packaged with ten inner packages per case.

-

Is the T27 quick change attachment system compatible with my angle grinder tool?

The T27 quick-change attachment style connection of the grinding wheel is widely used on most standard angle grinders - be sure to verify compatibility before ordering or starting any mixed brand projects!

3M™ Cubitron™ II Depressed Center Grinding Wheel is designed to exceed the performance of other grinding wheels in both cut and life, resulting in significant gains in productivity. The power of 3M Precision-Shaped Grain provides a cool, extra-sharp, quick cut that lasts longer than other wheels.

Ideal for Robotic Weld GrindingFor medium and high-pressure applications like robotic weld grinding, it is crucial to choose a high-performance abrasive that cuts fast and lasts long. The self-fracturing mineral in 3M™ Cubitron™ II Depressed Center Grinding Wheel ensures that your robot can grind welds for a longer time, reducing downtime and maximizing efficiency.

Grinding Wheel: Tips for Optimum UseA grinding wheel is a rigid resin-bonded wheel that is approximately 1/4" thick and is useful for removing welds from internal angles. Fiber discs are typically better for grinding welds on flat surfaces. A grinding wheel must be used with a right angle grinder that has a wheel guard designed for the size of the wheel used. Type 27 wheels have a depressed center that allows grinding at any angle without damaging the surrounding surface. The grinding wheel must have a maximum operating speed greater than or equal to the maximum speed of the grinder used.

3M Precision-Shaped Grain Maximizes Cutting Potential3M™ Cubitron™ II products have set a new standard for high-performing abrasives. 3M engineers used proprietary precision-shaped grain technology to maximize cutting potential, starting with 3M™ ceramic abrasive grain. Precision-shaped grain fractures into super-sharp points and edges that slice cleanly through metal, rather than plowing like traditional abrasives, ensuring extended high performance in heavy-duty production applications. The grains wear evenly and provide extra-long life and consistency with less grinding pressure. 3M™ Cubitron™ II abrasives outcut and outlast competitive ceramic abrasives, maximizing productivity and minimizing operator fatigue.