| SKU | 7100103097 |

|---|---|

| Legacy SKU | 66000235789 |

| UPC | 00051115340000 |

| Product Number | 708151 |

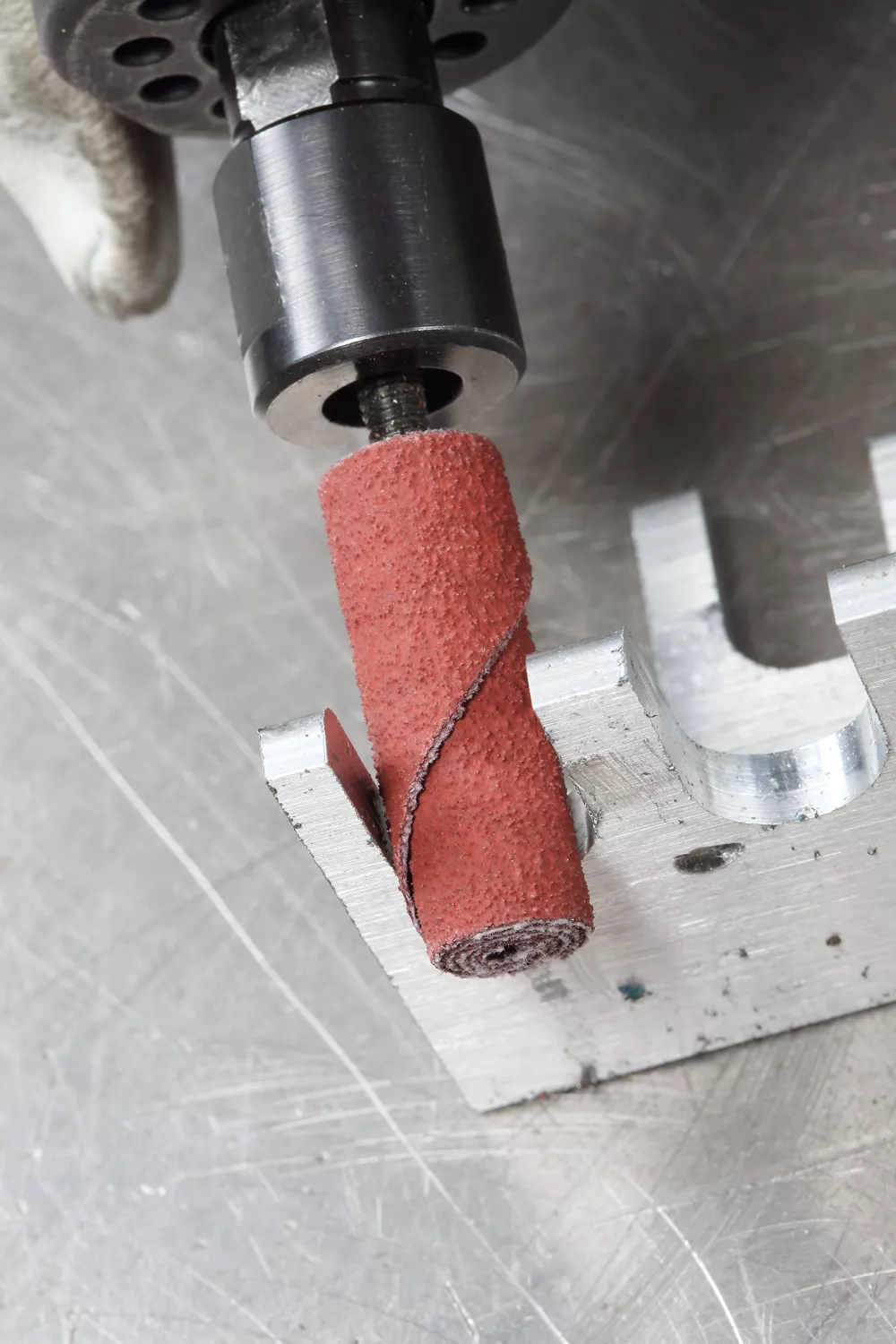

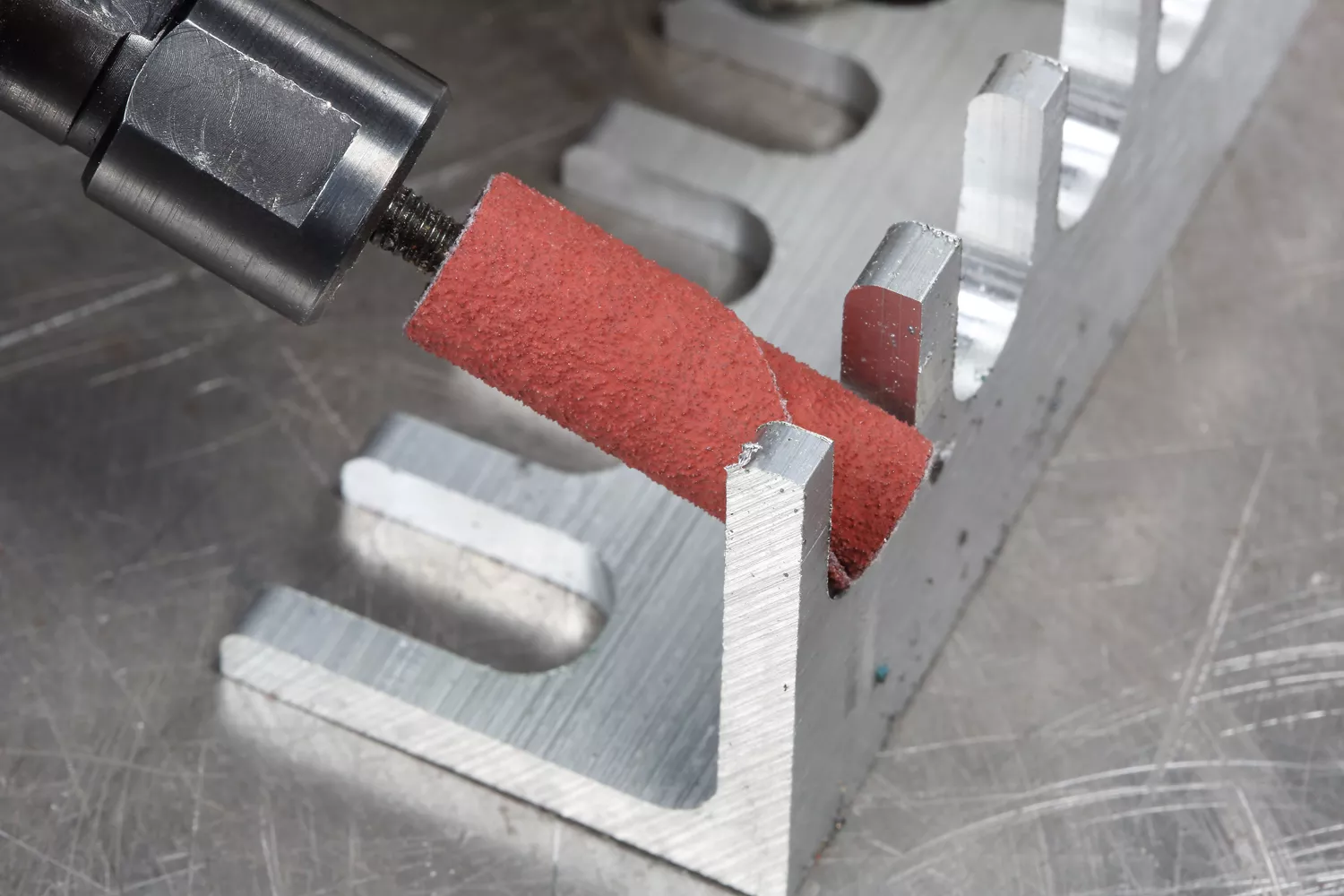

Standard Abrasives Aluminum Oxide Cartridge Roll is ideal for fast cutting on irregular contours and other hard-to-reach areas on all ferrous metals.

- Ideal for blending, deburring and polishing on ferrous metals

- Straight cylindrical shape enables operators to finish hard-to-reach areas

- Versatile range of minerals and grades are designed to meet specific project needs

- Arbor hole accommodates mandrel tool attachment, so abrasive may be used with various tools

- Multi-layer, multi-wear design enhances abrasive longevity and helps produce a consistent cut

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 3/4 in | 19.05 mm |

| Center Hole Diameter | 3/16 in | 4.763 mm |

Shipping Dimensions |

|

| Weight | 1.04 lb |

|---|---|

| Length | 4.25 in |

| Width | 4.25 in |

| Height | 4 in |

| Color | Brown |

|---|---|

| Maximum Speed | 16,000 rpm |

PRODUCT FAQ

-

What is the material used in 3M's Standard Abrasives A/O Straight Cartridge Roll?

The abrasive material used is aluminum oxide.

-

What are the dimensions of 3M's Standard Abrasives A/O Straight Cartridge Roll?

It has a diameter of 3/4 inches, length of 1 inch and thickness of 3/16 inches.

-

How many cartridge rolls are included per case?

There are 50 cartridge rolls included per case for maximum value and convenience.

-

Can this product be used for metal fabrication applications?

Yes! This product is designed to work with ferrous metals, including stainless steel, carbon steel, brass and bronze.

-

: Are there any grit options available besides the Grade #80?

: Yes! This particular roll also comes in grade #60 and #120 if you're looking for another option.

The Standard Abrasives™ Aluminum Oxide Cartridge Roll is a multi-layered abrasive tool that is perfect for polishing, edge breaking, and removing machine tool marks or flash. Its small size and shape make it ideal for blending, deburring, and polishing inside holes and diameters or on irregular surfaces and contours. The cartridge roll has an arbor hole that accommodates a mandrel tool attachment (sold separately). This mandrel attaches to a rotary tool such as a die grinder or drill and comes in different sizes to fit a variety of cartridge roll sizes. Together, the mandrel and cartridge roll enable the user to grind or finish hard-to-reach areas of a workpiece, such as angles and curves.

The Aluminum Oxide Cartridge Rolls come in a variety of sizes and grades, making it easy to tailor to unique project needs. Grades range from 36 to 400, producing a spectrum of finishes, from coarse to fine. It is made with aluminum oxide mineral, which cuts sharp and is friable – fragmenting under heat and pressure to reveal sharp cutting edges as it abrades the surface. The straight roll design is cylindrical, which helps it roll over irregular contours.

Benefits of a Multi-Layer DesignThe multi-layer, multi-wear design of Standard Abrasives™ Aluminum Oxide Cartridge Roll keeps it cutting sharp and helps it withstand repeated wear. As top layers wear down over time, underlying layers expose fresh mineral, so you get a consistent cut, part after part. Wrapping multiple layers of the abrasive material around into a roll contributes to its sturdiness and durability. A resin bond securely anchors mineral to the cloth backing – also enhancing the abrasive's toughness and strength. The closed-coat construction means mineral grains cover 100 percent of the cloth backing, so you get a smoother, more consistent finish. Seemingly small, these cartridge rolls conquer big challenges when space gets tight.