| SKU | 7100101321 |

|---|---|

| Legacy SKU | 60440314080 |

| UPC | 00076308897956 |

| Product Number | 237AA |

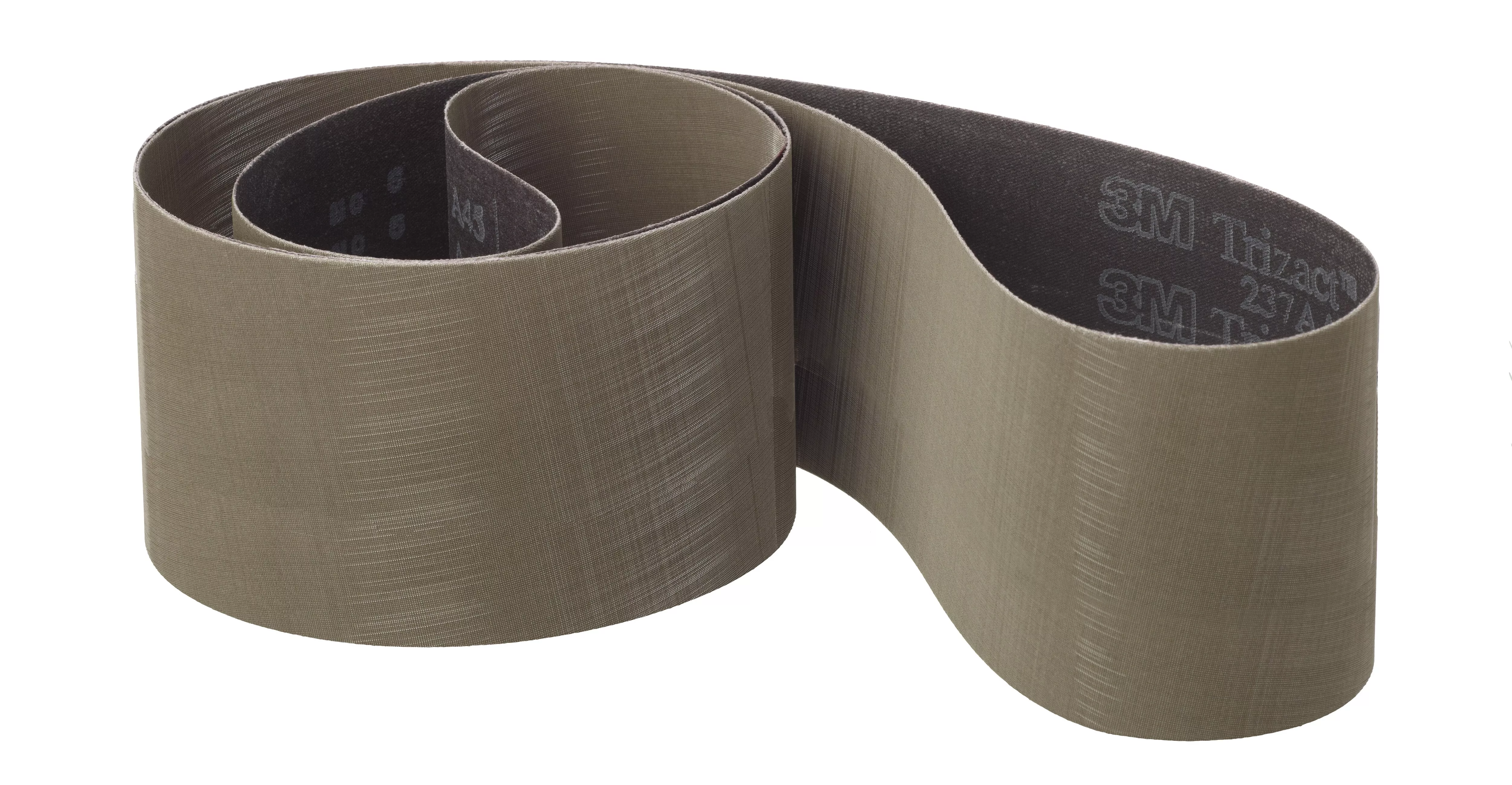

3M Trizact Cloth Cartridge Roll 237AA has a name that precedes it. Operators already know that cartridge rolls are built for flexibility; the small, cylindrical shape of cartridge rolls enables them to get in, out, over and around workpieces. Cartridge rolls can be especially helpful when you find yourself in a tight spot or corner. Use this roll for light deburring on a variety of rolls.

- Small, cylindrical shape enables abrasive to access internal diameters

- Aluminum oxide mineral cuts sharp without gouging the substrate

- Resin bond keeps abrasive running cool to help prevent part discoloration

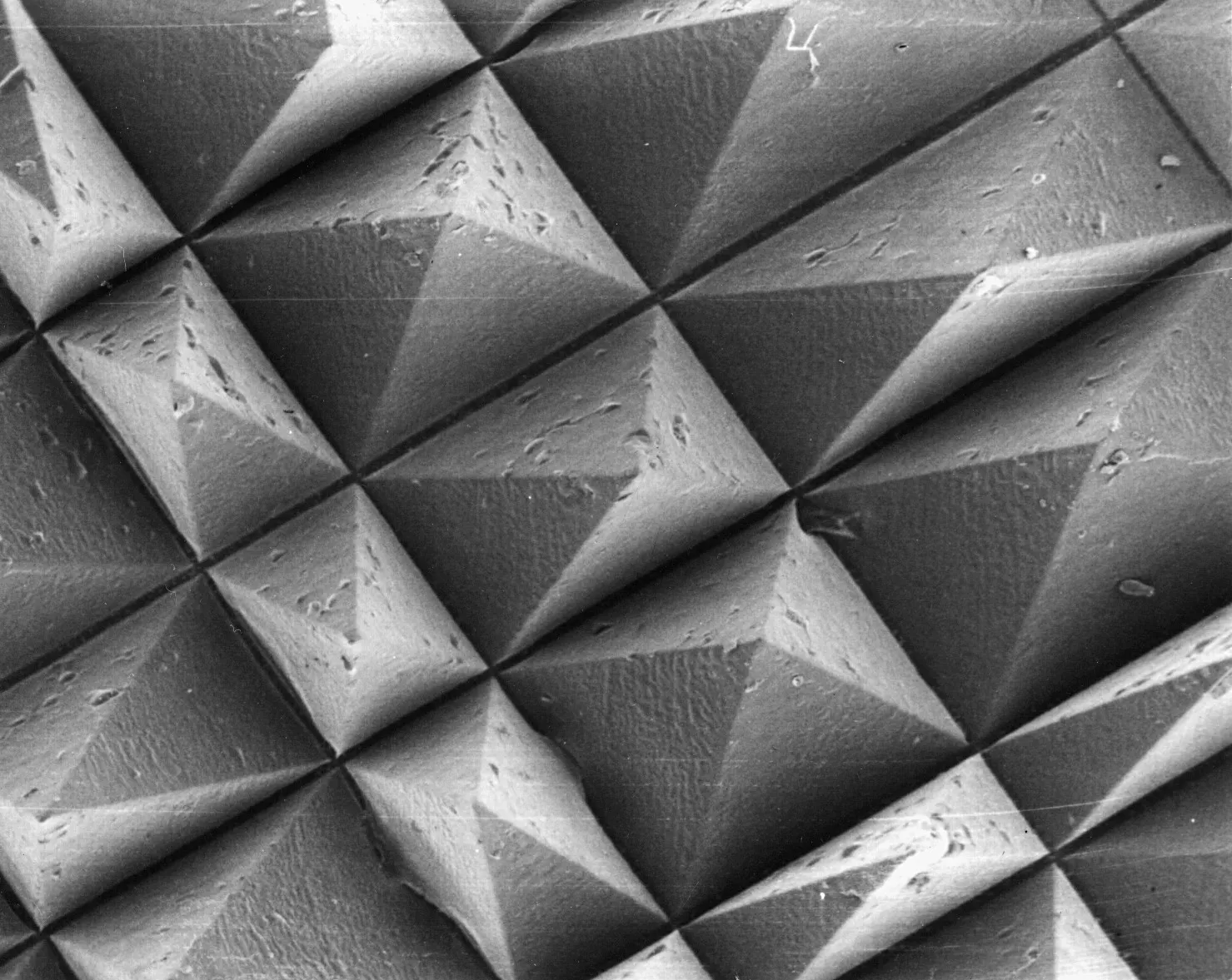

- Trizact™ abrasive features microreplication technology for ongoing, consistent cut

- X-weight cloth backing enhances durability and tear resistance

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 1/2 in | 12.7 mm |

| Center Hole Diameter | 1/8 in | 3.175 mm |

Shipping Dimensions |

|

| Weight | 0.622 lb |

|---|---|

| Length | 6.41732 in |

| Width | 5.7874 in |

| Height | 6.1811 in |

| Color | Gray |

|---|---|

| Maximum Speed | 24,000 rpm |

PRODUCT FAQ

-

What is 3M™ Trizact™ Cartridge Roll 237AA, and what is it used for?

The 3M™ Trizact™ Cartridge Roll 237AA is an abrasive cartridge roll that's designed to make metalworking faster and easier. It's typically used for sanding or polishing surfaces with intricate shapes.

-

How big are the rolls in this case?

All of the cartridge rolls in this case measure a half inch by one and a half inches, with an eighth inch thickness.

-

Can I use these cartridge rolls on wood or plastic surfaces?

No, these rolls are specifically designed for use on metals such as stainless steel or aluminum. Using them on other materials could lead to poor results.

-

Are there any special storage requirements for this product?

Yes, it's recommended that you store your cartridge rolls in their original packaging until you're ready to use them. This will help keep the abrasive material clean and prevent contamination from other particles.

-

How long can I expect each roll to last before needing replacement?

Unfortunately we cannot give a specific lifespan estimate because it depends largely upon how often they are used and what kinds of surfaces they come into contact with. However, high-quality carriers combined with precision-shaped grains provide outstanding consistency throughout the life of the product so they should not wear out easily under normal usage.

3M™ Trizact™ Cloth Cartridge Roll 237AA is made with aluminum oxide particles, which are known for their sharp cutting and fine finishing capabilities. This synthetic mineral can remove burrs and defects without damaging the substrate. The mineral is adhered to an X-weight cloth backing, which is durable and tear-resistant, making it suitable for use on edges and contours. The aluminum oxide mineral is resin-bonded to the cloth backing, and as the cartridge roll abrades the surface, the resin breaks down gradually to keep the substrate cool. The cartridge roll features an arbor hole to accommodate a mandrel (sold separately), which attaches to a die grinder.

When you need to finish a job in a tight space, trust 3M™ Trizact™ Cloth Cartridge Roll 237AA to get the job done.

3M Science, Applied with 3M™ Trizact™ Abrasives3M™ Trizact™ abrasives are designed to streamline light dimensioning and finishing work by reducing processing steps, increasing throughput, and creating consistency. This is achieved through a proprietary 3M technology called microreplication. During microreplication, small three-dimensional structures resembling pyramids are adhered to a backing. These "pyramids" contain layers of mineral, and they begin to break down after repeated use, continually exposing fresh mineral. The cycle of mineral renewal sustains the abrasive's sharpness. Ongoing sharp cutting action reduces the need to swap out the abrasive, contributing to higher throughput and increased productivity. Additionally, because the mineral is uniformly distributed over the abrasive surface, the workpiece receives fixed – rather than erratic – contact for a consistent cut.