| SKU | 7100093314 |

|---|---|

| Legacy SKU | 60410013118 |

| UPC | 00051125947336 |

| Product Number | 947A |

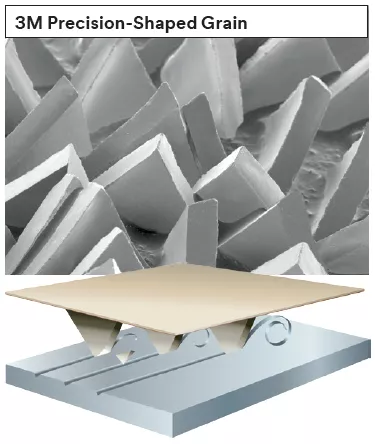

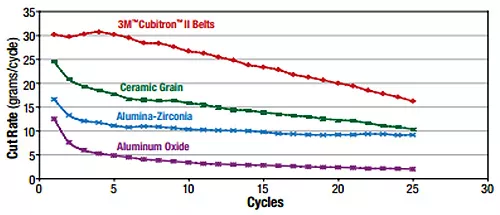

The 3M Cubitron II Abrasive Belt 947A built with 3M Precision-Shaped Grain cuts metal dramatically faster and cooler, and stays sharp longer than conventional ceramic belts. Its X-weight poly-cotton backing is flexible. This belt is optimized for low and medium pressure applications on stainless steel, mild steels, and aluminum.

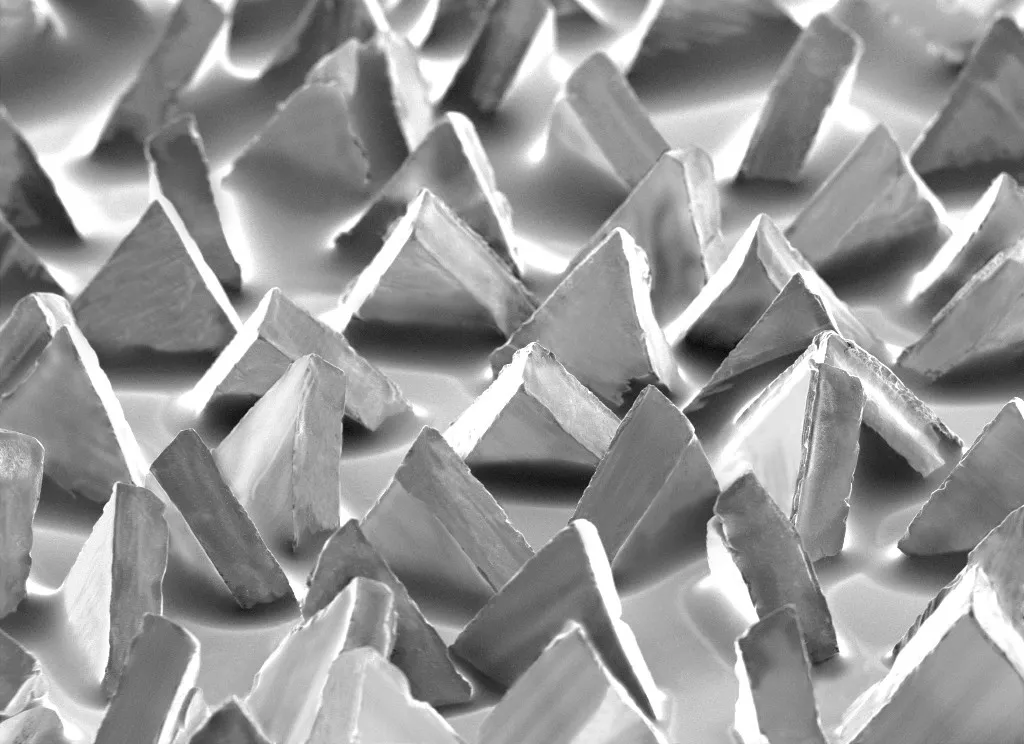

- 3M Precision-Shaped Grain slices through metals like a knife rather than gouging or plowing

- Removes material faster, with less pressure

- Includes a grinding aid for less grinding friction and cooler cutting

- Cool cutting action lessens the risk of heat-related damage to workpiece

- An X-weight poly-cotton backing is optimized for flexibility

- Lasts up to 4 times longer than conventional ceramic belts

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 5.09929 lb |

|---|---|

| Length | 11.9685 in |

| Width | 11.9685 in |

| Height | 9.2126 in |

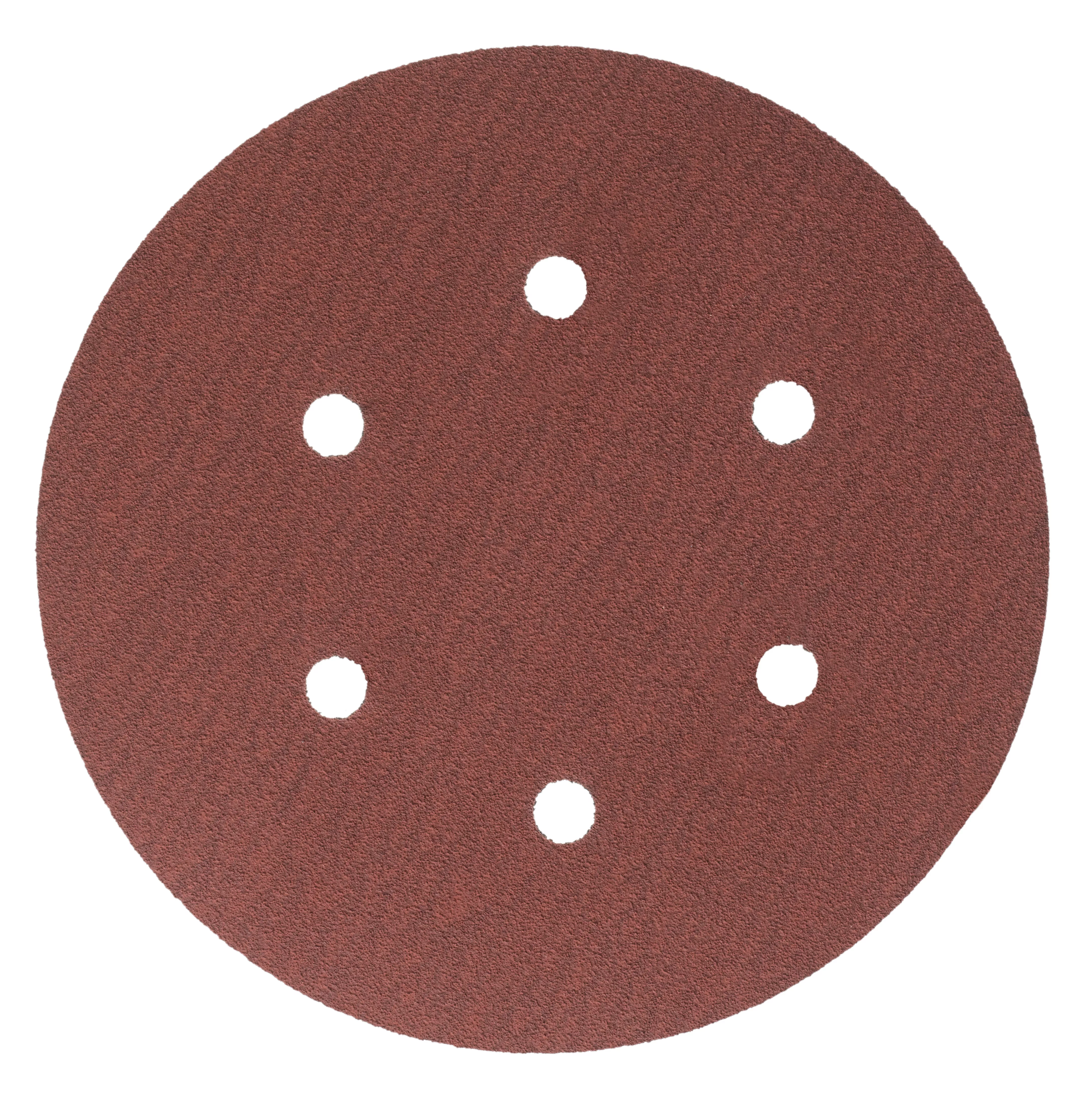

| Color | Maroon |

|---|

PRODUCT FAQ

-

What is the 3M™ Cubitron™ ll Cloth Belt 947A primarily used for?

The 3M™ Cubitron™ ll Cloth Belt 947A is designed for use on various metals such as carbon steel, stainless steel, and nickel alloys.

-

What type of abrasive material does it have?

This belt has precision-shaped ceramic grit that generates up to two times the cut-rate, durability, and life of other conventional ceramic abrasives.

-

What sizes are available in this product line?

It comes in multiple sizes ranging from 1/2" x 12" to large sanding belts of any length that can be attached by a compatible stationary belt machine.

-

. How many pieces come in one case?

. Each case contains fifty (50) units of this single-flex fabric-backed abrasive with Fabri-lok attachment system.

-

. Can these belts be used on wet surfaces?

A. Yes! For higher performance in wet surface grinding applications this abrasive features cool cutting technology that reduces heat build-up during operation while improving operator control over stock removal rates across a wide range of work materials.

A closed coat and a grinding aid make our 3M™ Cubitron II Abrasive Belt 947A an outstanding option for low to medium pressure applications on heat sensitive metals. The nature of the abrasive structure diverts heat to the swarf, keeping both belt and workpiece cooler. It is now available in grades 40+ (make to order), 60+, 80+ and now 120+ adding an improved solution for finer finishing applications.

Cutting Edge Performance for Low and Medium Pressure SandingA semi flexible Cubitron II belt the 3M™ 947A sports an X-weight poly-cotton backing. Among backing weights, an X-weight cloth is flexible and provides tensile strength as well. A great number of small belt sizes which are nimble and maneuverable so operators can get in, over and around intricate parts. These belts are good options for low-and-medium-pressure offhand operations for use on the following equipment:

- Backstands

- File Belt Sanders

- Inline Sanders

- Stroke Sanders

3M Precision-Shaped Grain is designed to continuously fracture to form sharp points and edges that easily "slice" through metal. It cuts faster, lasts longer and stays cooler. Conventional ceramic abrasive grain tends to "plow" through the metal, causing heat to build up in the workpiece and the abrasive – resulting in a slower cut, shorter belt life and undesirable effects, such as burnishing.

3M Science. The Beginning of Cubitron II.In 2009, 3M scientists had long believed abrasives would work better if each grain of the ceramic abrasive material was exactly the same size and shape. It would act more like a knife shaving off material and less like a plow bouncing along the surface, creating heat damage. The breakthrough came when they realized they could use microreplication technology 3M was already using to create reflective material for signs, and other purposes. Within a short time, they had created 3M's Precision Shaped Grain — identical triangular-shaped abrasive grains electrostatically oriented and distributed uniformly on an abrasive backing. The end result is faster, cooler cutting action, improved productivity, less operator fatigue and longer belt life.