| SKU | 7100093313 |

|---|---|

| Legacy SKU | 60410013126 |

| UPC | 00051125947343 |

| Product Number | 947A |

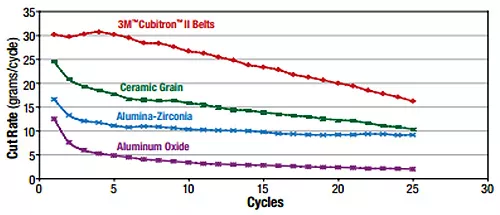

The 3M Cubitron II Abrasive Belt 947A built with 3M Precision-Shaped Grain cuts metal dramatically faster and cooler, and stays sharp longer than conventional ceramic belts. Its X-weight poly-cotton backing is flexible. This belt is optimized for low and medium pressure applications on stainless steel, mild steels, and aluminum.

- 3M Precision-Shaped Grain slices through metals like a knife rather than gouging or plowing

- Removes material faster, with less pressure

- Includes a grinding aid for less grinding friction and cooler cutting

- Cool cutting action lessens the risk of heat-related damage to workpiece

- An X-weight poly-cotton backing is optimized for flexibility

- Lasts up to 4 times longer than conventional ceramic belts

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 5.09929 lb |

|---|---|

| Length | 11.9685 in |

| Width | 11.9685 in |

| Height | 9.2126 in |

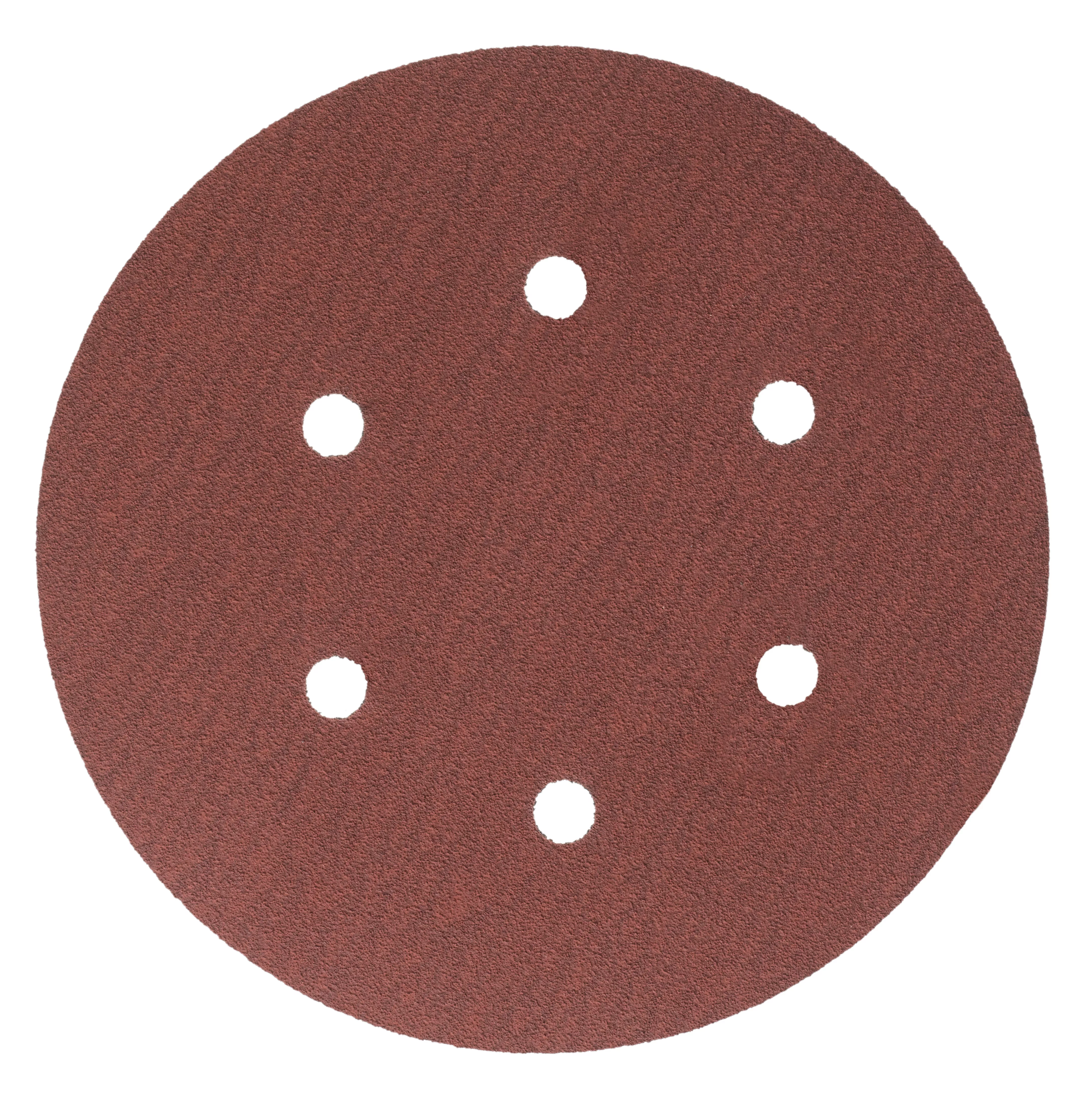

| Color | Maroon |

|---|

PRODUCT FAQ

-

What are the key features of the 3M™ Cubitron™ ll Cloth Belt 947A?

The 3M™ Cubitron™ ll Cloth Belt 947A is designed with proprietary precision-shaped ceramic grain technology for faster cutting and longer life. It also has a Fabri-lok belt attachment system for easy installation.

-

What is the size of each belt in this case?

Each belt in the case measures 3-1/2 inches by 15-1/2 inches, providing ample coverage for various applications.

-

How durable is the X-weight backing on these cloth belts?

The X-weight backing on these cloth belts offers added durability and strength, making them ideal for tough grinding applications.

-

How flexible is the Single-flex design of these belts?

The Single-flex design allows for easier conformability to contours and smoother operation during use, enhancing overall performance.

-

How many belts come in a single case of this product?

Each case contains 50 units of the 3M™ Cubitron™ ll Cloth Belt 947A, providing you with a good supply for your project needs.

A closed coat and a grinding aid make our 3M Cubitron II Abrasive Belt 947A an outstanding option for low to medium pressure applications on heat sensitive metals. The unique structure of the abrasive diverts heat to the swarf, keeping both the belt and workpiece cooler. We now offer this belt in grades 40+ (made to order), 60+, 80+, and 120+, providing an improved solution for finer finishing applications.

Cutting Edge Performance for Low and Medium Pressure SandingThe 3M 947A is a semi-flexible Cubitron II belt with an X-weight poly-cotton backing. The X-weight cloth provides flexibility and tensile strength, making it ideal for various applications. This belt is available in a range of small sizes, allowing operators to easily maneuver around intricate parts. It is a great option for low-and-medium-pressure offhand operations and can be used with backstands, file belt sanders, inline sanders, and stroke sanders.

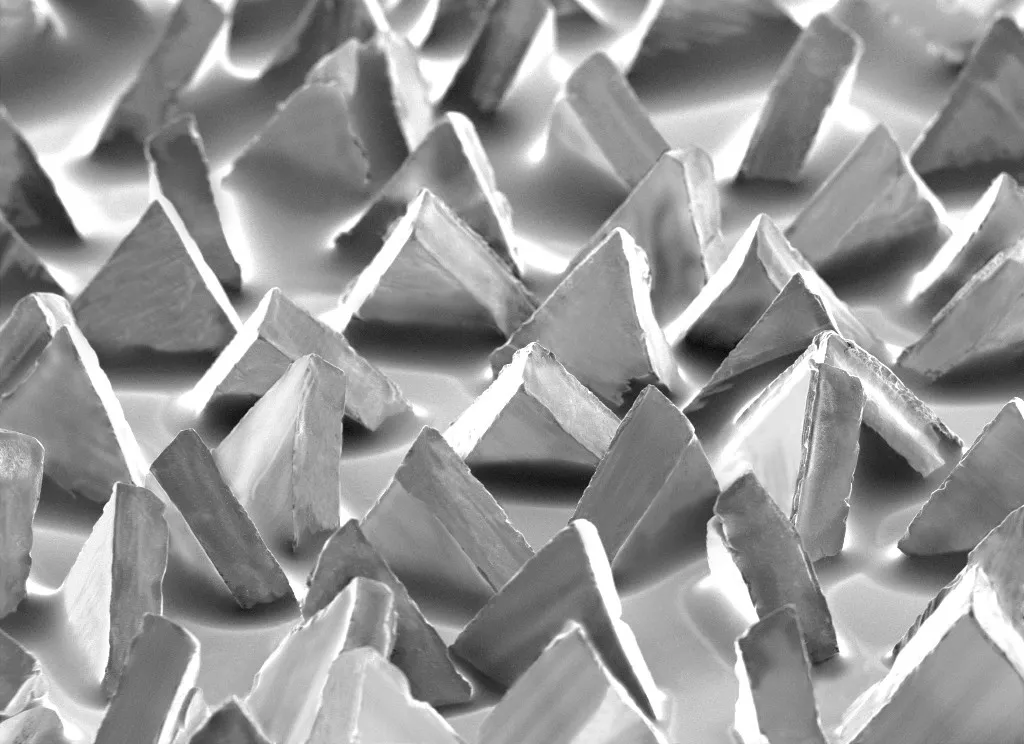

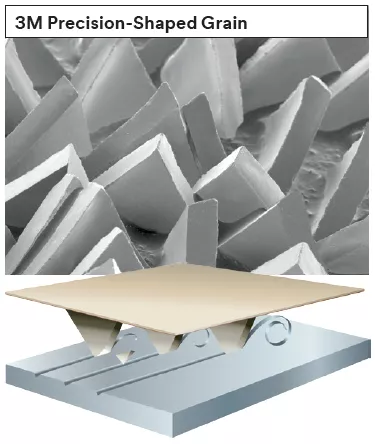

How 3M Precision-Shaped Grain Works3M Precision-Shaped Grain is designed to continuously fracture, forming sharp points and edges that effortlessly "slice" through metal. Unlike conventional ceramic abrasive grain, which tends to "plow" through the metal and generate heat, our Precision-Shaped Grain cuts faster, lasts longer, and stays cooler. This innovative technology prevents heat damage to the workpiece and the abrasive, resulting in a faster cut, longer belt life, and superior performance.

3M Science. The Beginning of Cubitron II.In 2009, our team of 3M scientists recognized that abrasives would perform better if each grain of the ceramic abrasive material was uniform in size and shape. They envisioned a grain that would act like a knife, shaving off material instead of plowing through it and causing heat damage. Leveraging our microreplication technology used for creating reflective materials, they developed 3M's Precision Shaped Grain. This technology involves electrostatically orienting and distributing identical triangular-shaped abrasive grains on an abrasive backing. The result is a belt that offers faster and cooler cutting action, improved productivity, reduced operator fatigue, and longer belt life.