| SKU | 7100083803 |

|---|---|

| Legacy SKU | 61500301322 |

| UPC | 00048011650876 |

| Product Number | 645DC |

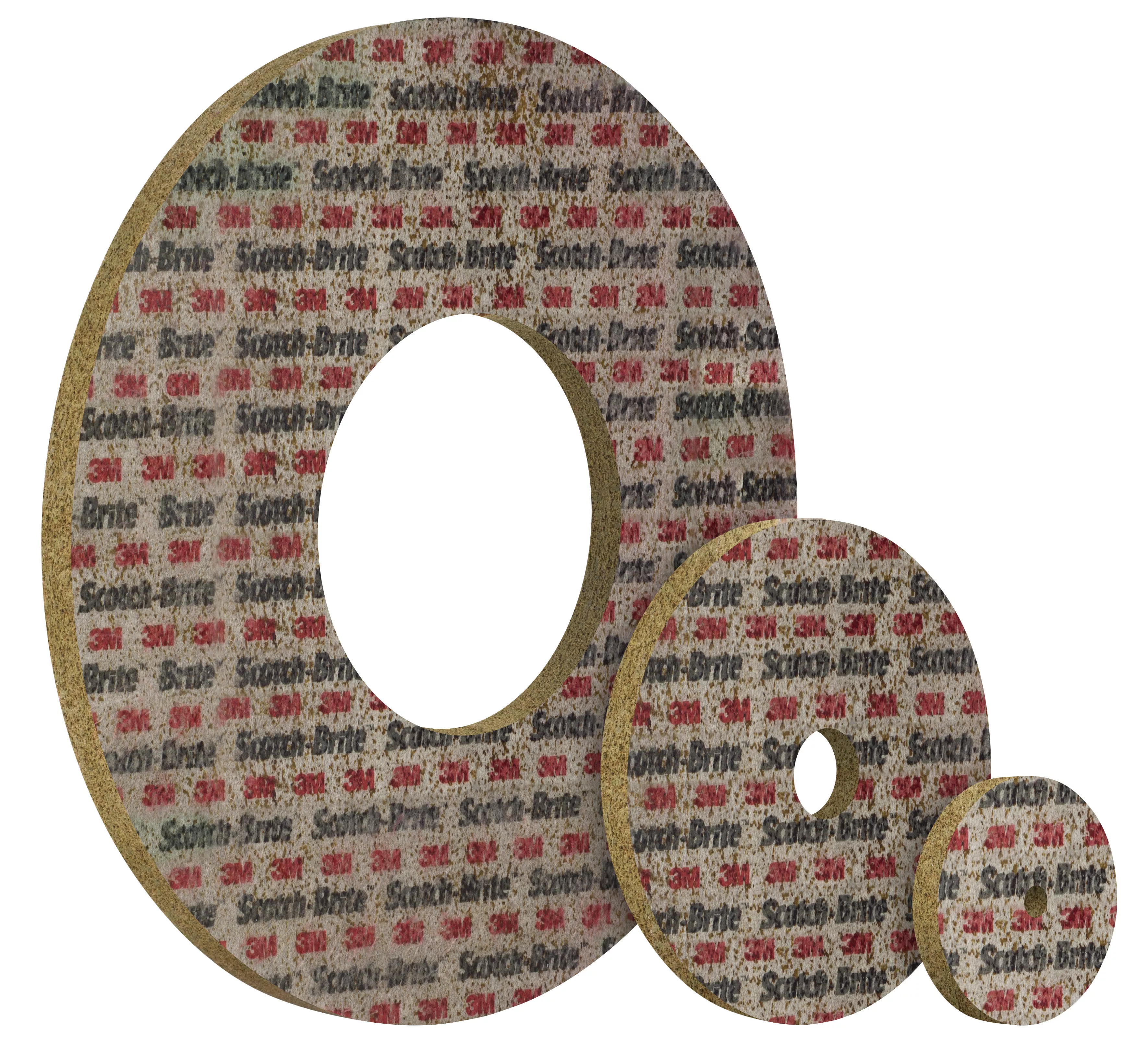

Scotch-Brite Diamond Wheel, 645DC is a unique surface conditioning wheel containing diamond mineral for removal and pre-polishing of extra-hard materials such as carbide thermal spray and ceramics.

- Removes and finishes thermal spray parts in one step with Ra in the 12-16 range

- Available in 12”, 6” and 3” diameters and in multiple thicknesses

- Provides a consistently fine, burr-free finish

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 3 in | 76.2 mm |

| Thickness | 1/2 in | 12.7 mm |

| Center Hole Diameter | 3/8 in | 9.525 mm |

Shipping Dimensions |

|

| Weight | 1.21409 lb |

|---|---|

| Length | 6.88976 in |

| Width | 6.88976 in |

| Height | 4.40945 in |

| Maximum Speed | 15,100 rpm |

|---|

PRODUCT FAQ

-

What is the Scotch Brite Diamond Wheel made of?

The 3M Scotch-Brite™ Diamond Wheel, 645DC is constructed with a flexible diamond mineral abrasives.

-

What are the dimensions of the wheel?

The wheel has dimensions of 3 inches x 1/2 inch x 3/8 inch.

-

What kind of surfaces can be worked on with this wheel?

This diamond wheel can be effectively used for grinding and finishing various materials such as hard plastics, metals, carbon fiber reinforced plastic (CFRP), ceramics and glass-filled composites.

-

How many pieces come in a case?

Each case includes a set containing ten wheels that which you can replace as needed!

-

. Are there any safety instructions or precautions I should take while using these products?

. Yes! Always ensure to wear appropriate personal protective gear- eye protection goggles or face shield etc., before starting your work to prevent particles from entering into eyes or clothes. Please read technical bulletins for more safety information laid out by our company's policies & recommendations that we care about so much for everyone's safety!

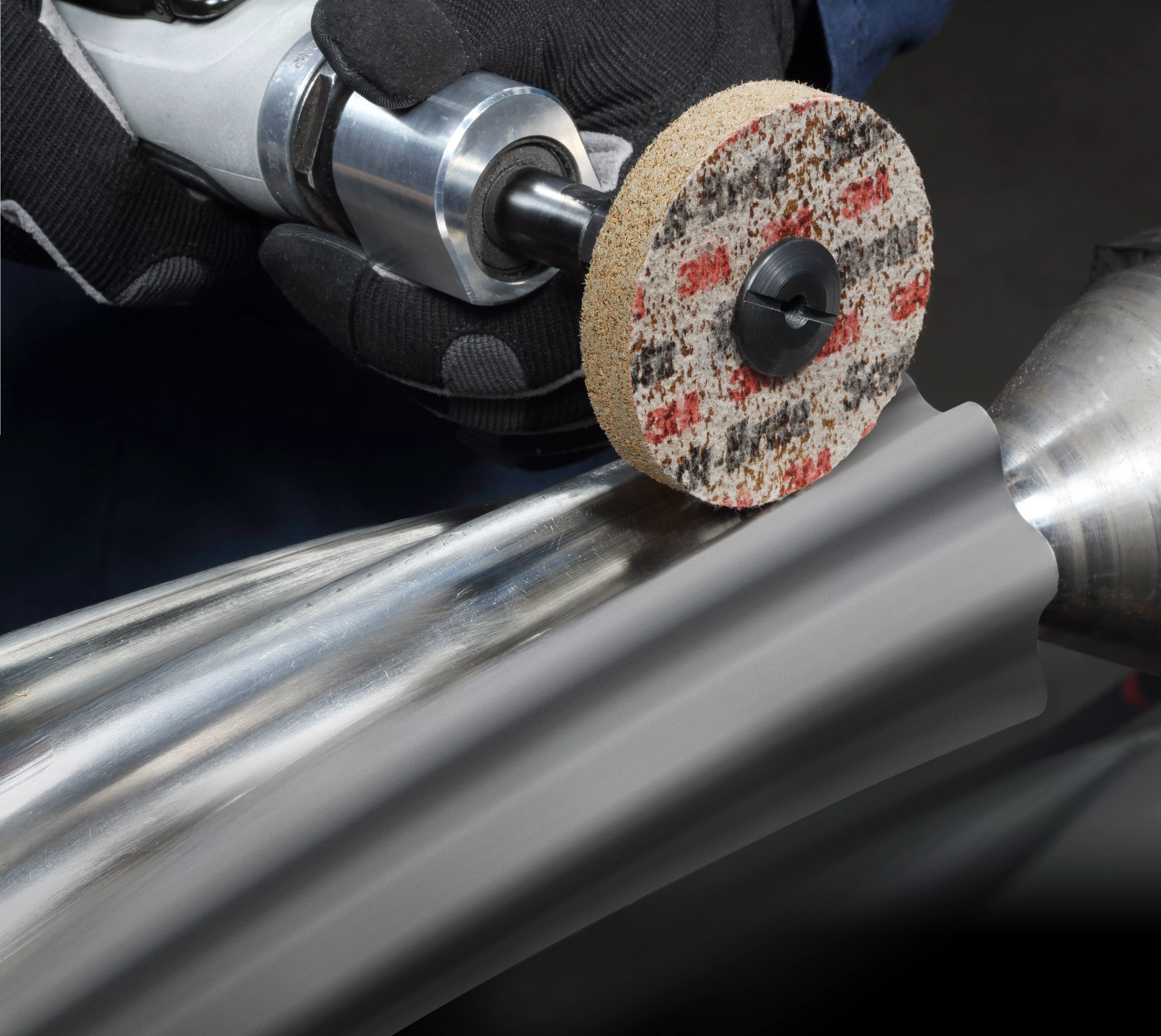

The Scotch-Brite™ Diamond Wheel, 645DC is designed to provide significant process improvements in the grinding and finishing of thermal spray and other hard-to-grind substrates. Its diamond mineral abrasive provides a consistently fine, burr-free finish throughout the life of the wheel.

Discover the Scotch-Brite™ AdvantageScotch-Brite™ abrasives are unique due to their nonwoven technology. The abrasive mineral is interspersed on synthetic fibers using resin, creating an open web construction. This design allows excess material to escape, preventing the mineral from becoming worn down by debris. The mineral stays sharper longer, enhancing cut performance and increasing abrasive service life. The spring-like nature of the fibers works well on contours and responds to subtleties on the surface. The responsive design effectively removes unwanted burrs, soils, and contaminants without ruining the base material, resulting in a consistent and uniform finish, part after part.

Typical Applications- Composites

- Carbon fiber

- Thermal spray

- Hard-to-grind surfaces