| SKU | 7100074611 |

|---|---|

| Legacy SKU | 66000028499 |

| UPC | 00051115352492 |

| Product Number | 877012 |

The Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.

- Compact abrasive lightly deburrs and finishes the workpiece without changing part geometry

- Mounted point is securely fastened to a metal spindle for safe use with die grinders

- Non-woven construction resists loading during use

- Unitized production method compresses abrasive web for greater density and durability

- Resists smearing for cleaner surfaces and less preparation

- Self-dressing material exposes fresh grain through the life cycle

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 3.04899 lb |

|---|---|

| Length | 15.55118 in |

| Width | 6.45669 in |

| Height | 3.8189 in |

| Color | Light Gray |

|---|---|

| Maximum Speed | 34,500 rpm |

PRODUCT FAQ

-

What is the 3M Standard Abrasives™ Unitized Mounted Point 877012 suitable for?

The 3M Standard Abrasives™ Unitized Mounted Point 877012 is ideal for precision deburring, blending and polishing on all metals.

-

What are the dimensions of the abrasive point?

The size of each mounted point is A21 x 1/4 in.

-

How many points come with each case of this product?

This product contains five unitized mounted points per inner pack and fifty inner packs per case resulting in a total of two hundred and fifty pieces in one case.

-

Can these abrasives be used by hand or only with a power tool?

The Standard Abrasives™ Unitized Mounted Points can be used on both bench motors or straight grinders but they work best when instated using an electrical rotary tool such as Dremel or drill press.

Suitable Shapes and Sizes for a Variety of Workpieces

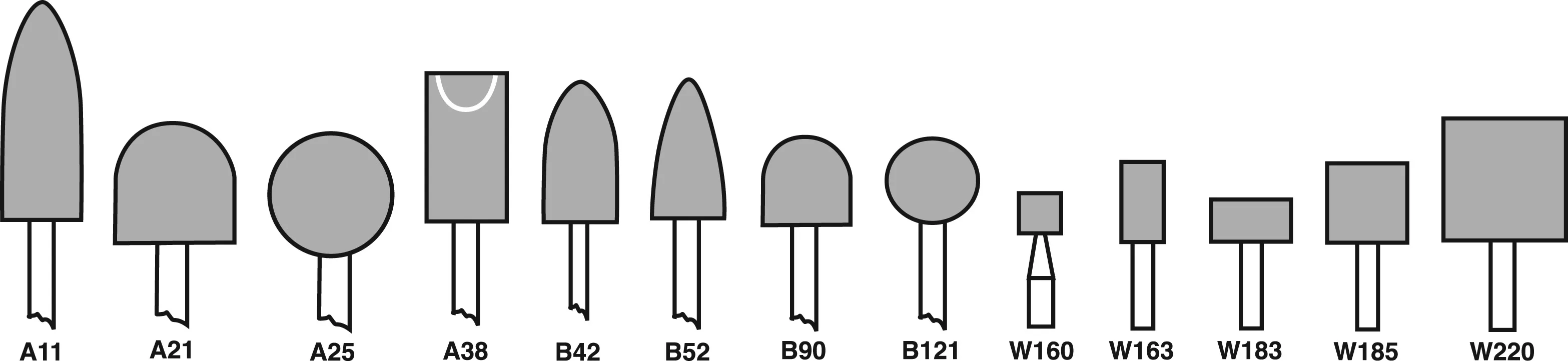

Standard Abrasives™ Unitized Mounted Point is available in a variety of ANSI (American National Standards Institute) shapes and sizes, making it ideal for light blending and deburring of smaller workpieces. The range of abrasive sizes helps operators to effectively finish various parts. The abrasive point is permanently fastened to a metal spindle, allowing it to be securely run at high speed with a die grinder.

Unitized Products Excel at Consistent Finishes

Standard Abrasives™ Unitized Mounted Point reduces the risk of smearing or blemishing the surface. It also features non-woven web that is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.

Unitized products are created by compressing and curing multiple layers of abrasive material together. The tough, layered, unitized construction gives the abrasive higher density and more durability, making the Standard Abrasives™ Unitized Mounted Point ideal for small workpieces that require a consistent finish. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

Super Sharp Silicon Carbide Leaves a Fine Finish

Silicon Carbide is harder and sharper than either aluminum oxide or zirconia alumina. It is most commonly used for low-pressure applications such as paint prep and the final stages of whitewood sanding. While it may have a shorter life than aluminum oxide, it produces a finer, brighter finish.

The unitized mounted points are color-coded by grade for easy identification in the workroom. Coarse grade points are dark gray, medium grade points are blue, and fine grade points are light gray.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Unitized products offer many benefits for heavy-duty jobs. They invigorate deburring, cleaning, blending, and finishing applications by helping operators reduce finishing steps, minimize costs, and achieve greater throughput.