| SKU | 7100048982 |

|---|---|

| Legacy SKU | 60440234692 |

| UPC | 00051141281179 |

| Product Number | 375L |

The 3M Stikit Film Disc 375L is engineered to deliver outstanding tear resistance, flexibility, and a consistent, uniform finish on a variety of substrates. Premium aluminum oxide abrasive grain offers a fast cut-rate and extended product life for greater productivity.

- Premium aluminum oxide abrasive offers a fast cut and long life, and performs well on many surfaces

- 3M™ Stikit™ backing provides easy application and removal, and a liner prevents dust and debris from contaminating the adhesive

- Durable film backing is tear-resistant and provides a uniform, consistent finish

- Open coat construction provides an aggressive cut

- Load-resistant coating helps prevent dust and debris from clogging the disc

- Excellent for contoured surfaces

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

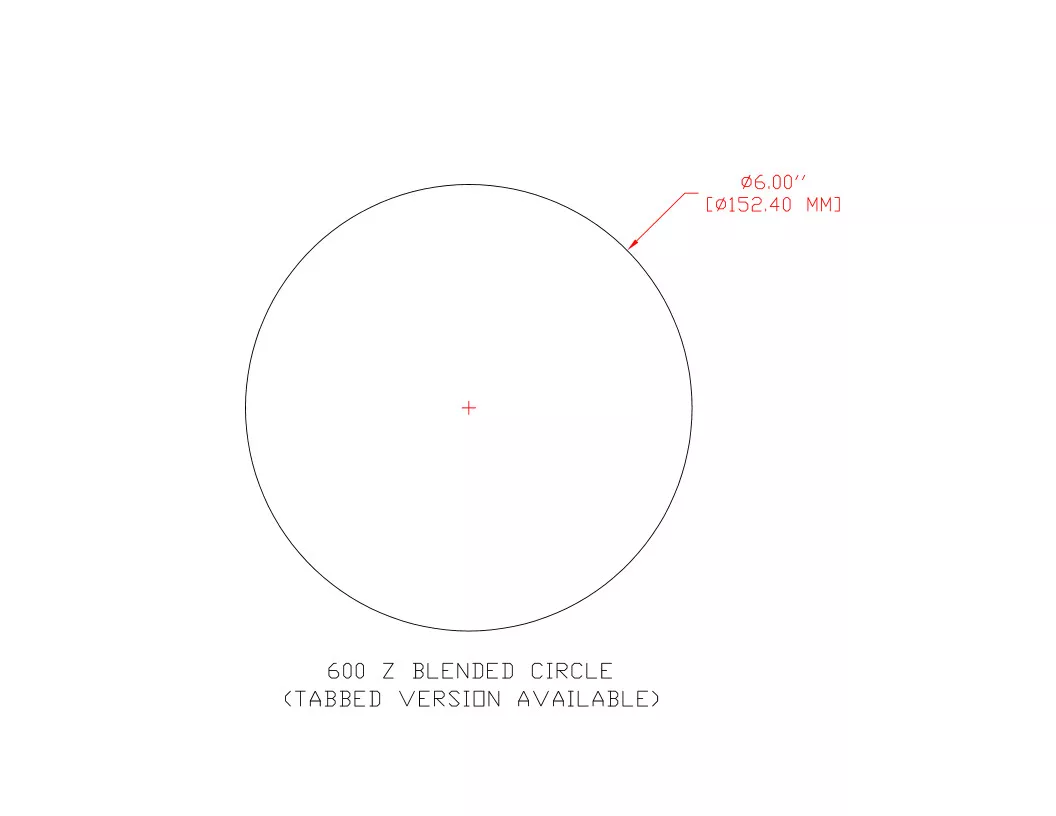

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 6.28979 lb |

|---|---|

| Length | 11.29921 in |

| Width | 6.88976 in |

| Height | 7.28346 in |

| Color | Reddish Brown |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M Stikit Film Disc 375L used for?

The 3M Stikit Film Disc 375L is designed for use in automotive refinishing, wood sanding, metal finishing, composites and gelcoat leveling.

-

What grit size does the P1500 grade correspond to on a sandpaper scale?

The P1500 grade corresponds to a fine grit size of about 12-15 microns.

-

How many discs are included in each case of the Die 600Z packaging configuration?

There are a total of 250 film discs included in each case of the Die 600Z packaging configuration.

-

Is it easy to remove the film disc from its liner without any tear or residue issues?

Yes, with proper application techniques it should be easy to quickly and cleanly remove the film disc from its liner backing.

This durable film construction provides the tear resistance needed for the use of coarse grades in high-production metalworking environments, particularly where edge wear is a concern. The film backing generates a uniform and consistent finish. With a 3M™ Stikit™ backing, this disc is easy to attach to a backup pad (sold separately), and easy to remove.

The 3M™ Stikit™ Film Disc 375L is suitable for a variety of applications. When the goal is a superior wood finish, the 375L film disc in medium grades conforms well to the contours and rounded edges of challenging work surfaces to deliver a superior finish. Woodworking applications are further enhanced by a load-resistant coating and open coat construction, which reduce clogging and extend the life of the abrasive. For pre- and post-paint finishing, versatility is key, and the 375L film disc in fine grades is designed to deliver a superb uniform finish on plastics and clear coat technologies commonly used in the transportation industry.

The 3M™ Stikit™ Film Disc 375L is designed for use with a random orbital sander and our Stikit™ backup pad (sold separately). It comes in a range of grades for various applications from rough sanding to very fine finishing.

The line of Stikit™ discs come ready to use with a pressure sensitive adhesive coating on the backside so that attaching them to the Stikit disc pad is as simple as pressing on a sticker. And because the adhesive is pressure sensitive, the disc can be peeled off of the disc pad just as easily, leaving a clean surface for the next disc. A convenient liner prevents the adhesive from becoming dirty and keeps the backing sticky until applied.

Film-backed discs have excellent tear-resistant properties and provide a very uniform finish and consistent results with each use. This makes them an excellent option when working on paint, e-coats, primers, gel coats, glass, acrylics and solid surface material, wood topcoats and anywhere else a perfect finish is needed.

An aluminum oxide abrasive mineral is featured in the manufacture of our 3M™ Stikit™ Film Disc 375L. Aluminum oxide is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut-rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys.