| SKU | 7100028146 |

|---|---|

| Legacy SKU | 70001608291 |

| UPC | 00051125026598 |

| Catalog Number | R3227 |

| Product Number | R3227 |

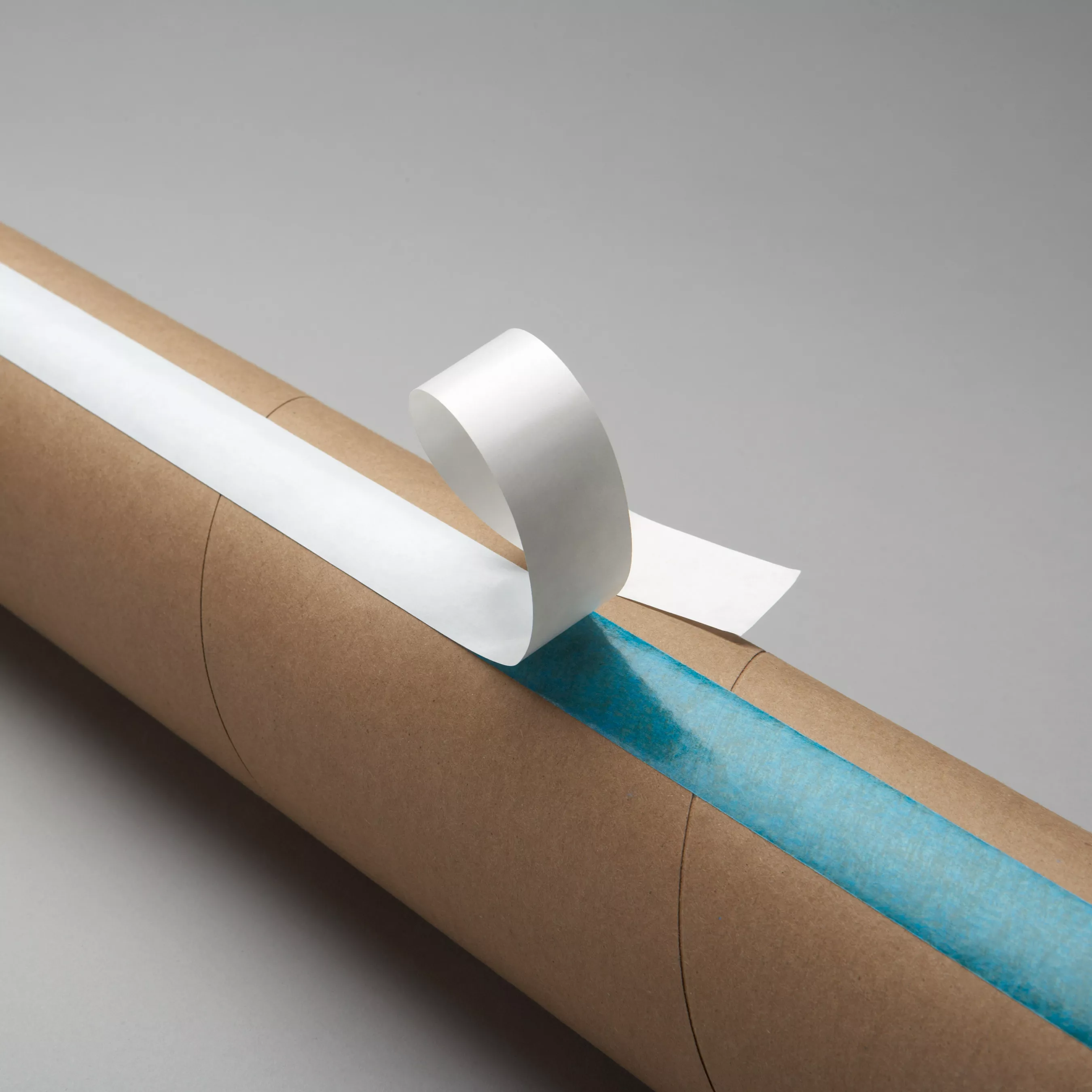

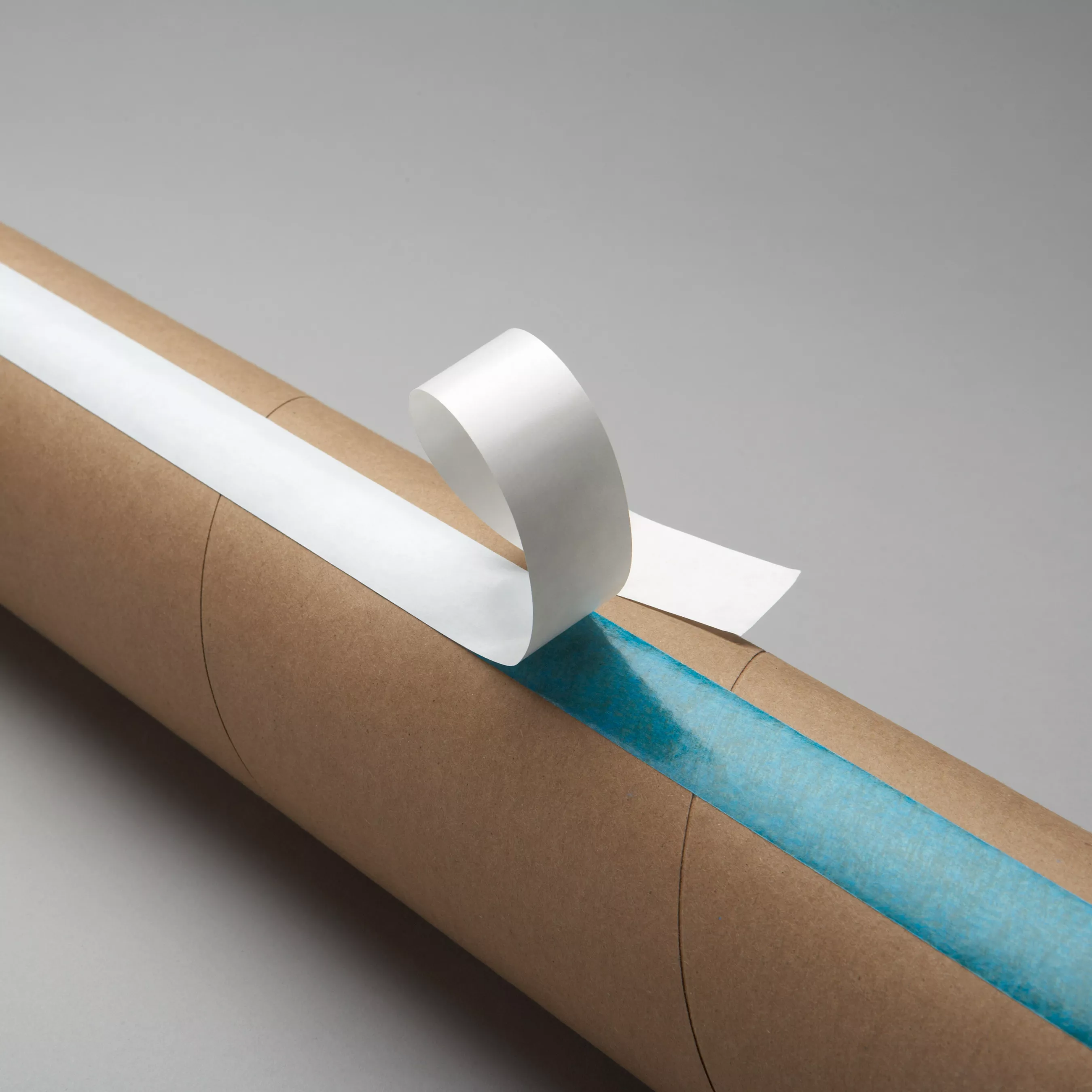

3M Repulpable Web Processing Double Coated Tape R3227 is a temporary splicing tape used to aide in the processing of paper within the paper mill. The backing and adhesive is engineered for optimum strength for every type of splice: flying, overlap, butt and general purpose. It provides the required shear strength, high tack and heat resistance necessary for dependable productivity.

- Repulpable material prevents broke contamination from non-repulpable splice material

- Tissue backing is thin and porous to allow adhesive penetration of sheet and engineered for optimum strength in a variety of splices

- Adhesive is designed to bond to a variety of paper substrates with high shear strength to perform in a variety of temporary splicing app

- High heat resistance (up to 400°F/200°C) allows tape to perform in a variety of printing applications

- Packaged in sealed plastic bags helps protect constant moisture content of unused tape

Product Dimensions |

Imperial | Metric |

| Weight | 1.68213 lbs | |

|---|---|---|

| Width | 5-1/2 in | |

| Length | 2.835 in | |

| Height | 5-1/2 in | |

| Thickness | 3 mil | 0.089 mm |

Shipping Dimensions |

|

| Weight | 21.15776 lb |

|---|---|

| Length | 11.61417 in |

| Width | 11.61417 in |

| Height | 9.76378 in |

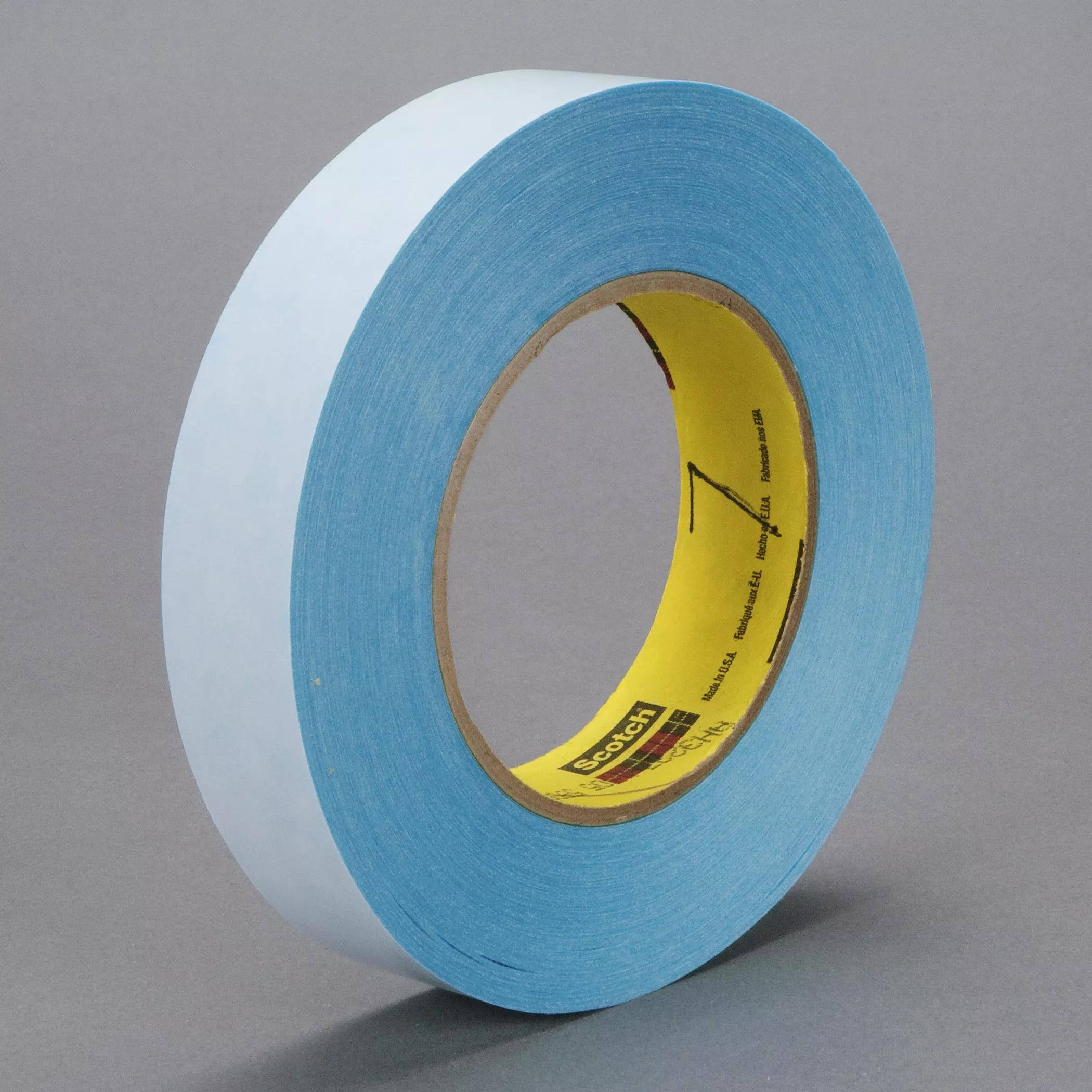

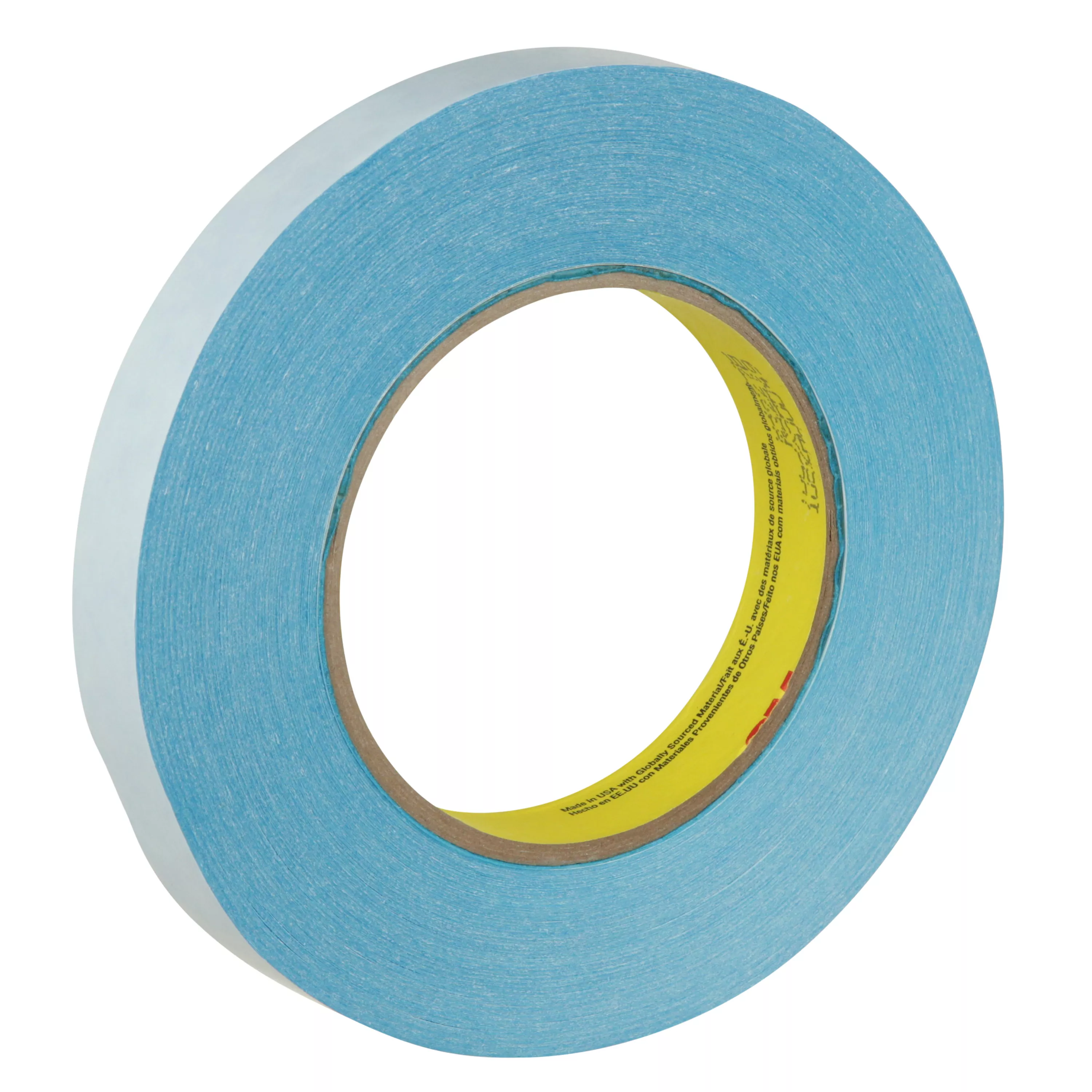

| Color | White |

|---|

PRODUCT FAQ

-

### Q: Is the 3M™ Repulpable Double Coated Tape R3227 environmentally friendly?

Yes, the 3M™ Repulpable Double Coated Tape R3227 is designed to be repulpable for easy recycling and environmental sustainability.

-

### Q: What are the dimensions of each roll in a case of the 3M™ Repulpable Double Coated Tape R3227?

Each roll of the 3M™ Repulpable Double Coated Tape R3227 measures 72 mm x 55 m.

-

### Q: How many rolls come in a single case of the 3M™ Repulpable Double Coated Tape R3227?

There are a total of 12 rolls per case of the 3M™ Repulpable Double Coated Tape R3227.

-

### Q: Can this tape be used for outdoor applications or is it mainly for indoor use?

The 3M™ Repulpable Double Coated Tape R3227 is primarily recommended for indoor use as it may not withstand extended exposure to outdoor elements.

-

### Q; Does this tape work well on various surfaces such as cardboard, paper, or plastic?

Yes, the versatile adhesive properties of the double-coated tape make it suitable for adhering to cardboard, paper, plastics, and other common packaging materials.

Introducing the 3M Repulpable Web Processing Double Coated Tape R3227, a versatile and reliable solution for a wide range of splicing applications. This double coated tape is specifically designed for core starting, pull-through, and temporary splicing tasks. With a thickness of 3.5 mil, it offers the perfect balance of strength and flexibility.

The tape consists of a tissue carrier backing and a repulpable adhesive, both engineered to deliver exceptional performance. The tissue backing is thin and porous, allowing the adhesive to penetrate the sheet for a secure bond. It is also designed to provide optimum strength for various types of splices, ensuring reliable and durable results.

With a high shear strength, this tape can withstand temperatures of up to 400F/200C, making it suitable for demanding applications. Whether you're working with coated or uncoated papers, or other cellulosic materials, the 3M Repulpable Web Processing Double Coated Tape R3227 is up to the task.

Applying the tape is a breeze, thanks to its paper liner. It is easy to handle and apply, saving you time and effort. Plus, it is FDA compliant and meets all regulations for repulpable tape, giving you peace of mind.

Recommended Applications- Core starting

- Roll closing

- Temporary and pull through splicing on coated and uncoated papers and cellulosic materials

- Splicing at sheeting and other paper converting operations

One of the standout features of the 3M Repulpable Web Processing Double Coated Tape R3227 is its repulpable adhesive. This adhesive is specially formulated to prevent broke contamination, ensuring a clean and efficient splicing process.

The tape meets or exceeds TAPPI UM-213, procedure A, and is FDA compliant with 21 CFR 176.170, which regulates components of paper and paperboard in contact with aqueous and fatty food. This makes it a reliable choice for applications where hygiene and safety are paramount.