| SKU | 7100023281 |

|---|---|

| Legacy SKU | 62372093351 |

| UPC | 00021200491306 |

| Catalog Number | 3762 LM |

| Product Number | 3762LM |

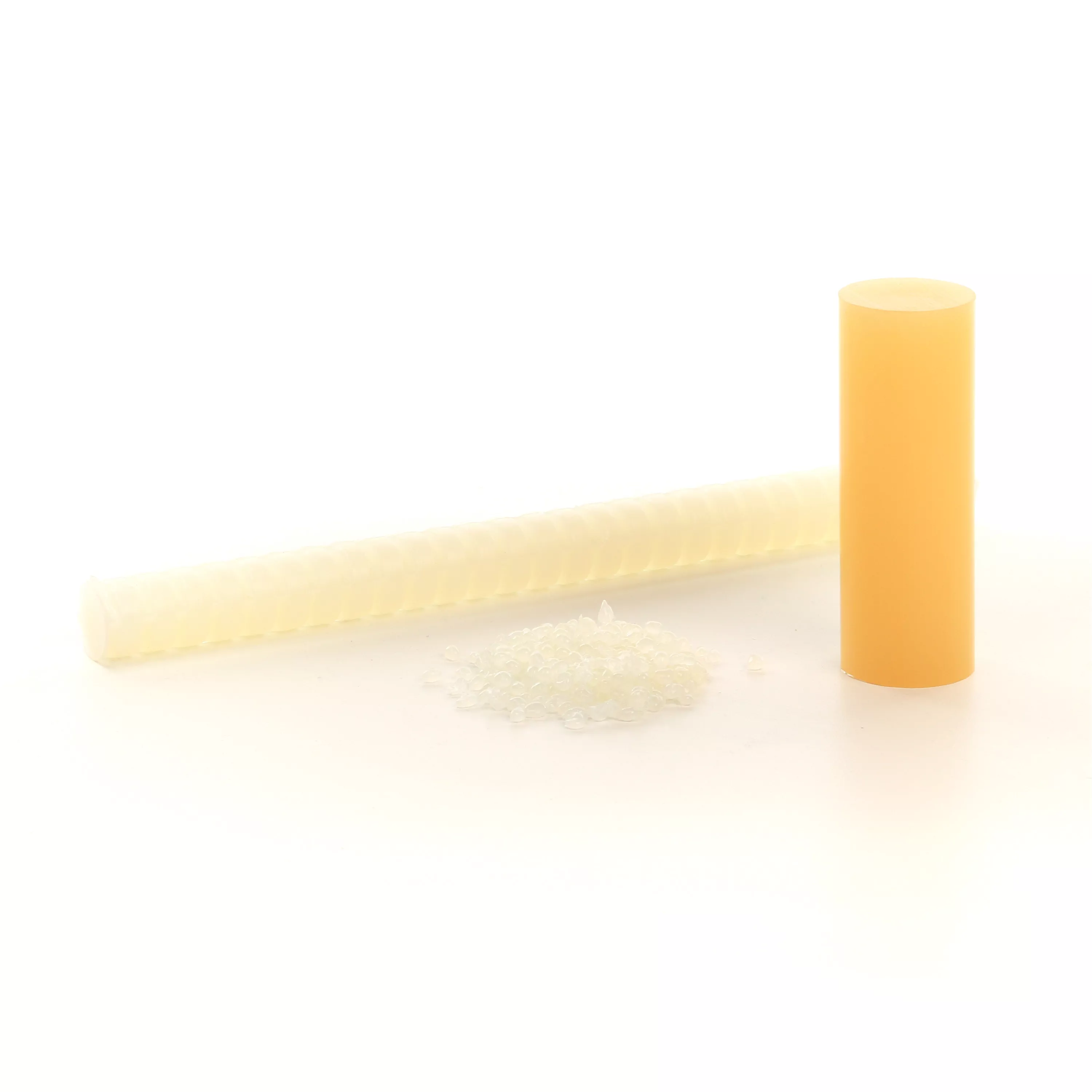

3M Hot Melt Adhesive 3762LM is a 100% solids, fast-setting hot melt adhesive designed for packaging and shipping applications. It is ideal for bonding corrugated fiberboard cartons, wood, particle board, chipboard and foam. The recommended application temperature range is 250-270F (121-132C).

- Aggressive hot tack rapidly achieves handling strength

- Short open time allows for fast assembly lines

- Securely bonds difficult to seal substrates such as lightly waxed surfaces

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 23.26538 lb |

|---|---|

| Length | 11.85039 in |

| Width | 7.99213 in |

| Height | 14.84252 in |

| Color | Light Amber |

|---|

PRODUCT FAQ

-

What is the best way to use 3M™ Hot Melt Adhesive 3762LM?

To ensure better bonding, we recommend using our hot melt adhesive at a temperature between 325°F and 375°F (depending on substrate) with a coverage of approximately 1/4 inch per second. The speed should be adjusted based on how fast glue exits the nozzle.

-

How long does it take for the adhesive to set after application?

This will depend on many factors such as air temperature, humidity and materials being bonded. However, under normal conditions, this light amber hot melt adhesive sets in just a few seconds providing quick handling strength.

-

Is this product eco-friendly?

Yes! Our Hot Melt Adhesive is free from solvents that are harmful to humans or the environment making it one of the most environmentally friendly bonding solutions available today.

3M™ Hot Melt Adhesive 3762 is a thermoplastic resin that is 100% solids and designed to quickly grab and seal in high-volume production settings such as packing, woodworking, and assembly. This adhesive is perfect for carton closures and provides adhesion to wood, paperboard, corrugated, and other fibrous substrates. It has strong shear strength, which ensures that packages stay sealed and components stay bonded under most conditions. The low viscosity prevents stringing even at fast production speeds. With a 25 second open time and a 1/8" bead, it is easy to position and adjust for fit, making it ideal for packaging, woodworking, and applications that involve fibrous materials.

Recommended Applications- General packaging

- Securing wood supports and reinforcements

- Repacking chipboard

- Point-of-purchase displays

- Trade exhibits

- Bonding waxed surfaces

Hot melt adhesives, also known as glue sticks, are liquefied thermoplastic adhesives that come in both low and high-temperature versions. Low temperature hot melt adhesives are applied at 250ºF/121ºC temperatures, which makes them ideal for bonding electronics, plastics, cloth, and other heat-sensitive materials. High temperature hot melt adhesives are applied at 380ºF/193ºC and produce a stronger bond than the low temperature hot melts. Melted adhesive is extruded through a nozzle using a 3M™ Hot Melt Applicator by either pneumatic pressure, a mechanical trigger mechanism, or with pressure applied directly on the stick. Different nozzles can be used to apply thin, wide strips or narrow, thicker beads. Hot melt adhesive generally sets quickly, ranging from a few seconds to a few minutes, depending on the adhesive formulation.

Bringing Better Ideas to the Surface through Science and InnovationIn the 3M Industrial Adhesives and Tapes Division, we use the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies worldwide. Our technologies help customers like you deliver competitive products to the market faster and more efficiently.