| SKU | 7100019072 |

|---|---|

| Legacy SKU | 60440240871 |

| UPC | 00051141287607 |

| Product Number | 28760 |

The 3M Cubitron II Cut and Grind Wheel features 3M Precision Shaped Ceramic Grain to bring you an exceptionally fast-cutting and long-lasting wheel for use on both stainless steel and mild steel. These versatile wheels are designed to be used both as a grinding wheel and as a cut-off wheel making them ideal for cutting, grinding, gouging and more.

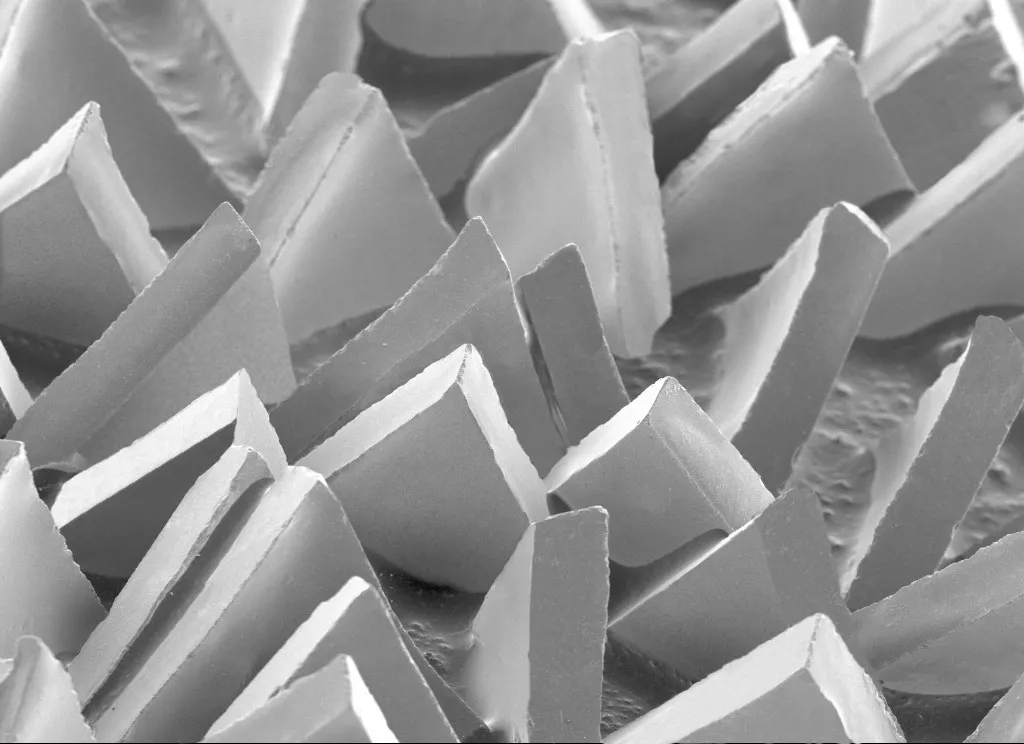

- 3M™ Cubitron™ II Cut and Grind wheels are engineered with precision-shaped grain to cut faster than competitive ceramic products

- Triangular shaped ceramic grain wears evenly, runs cool, and optimizes mineral breakdown, for extra-long life

- Rigid, reinforced resin-bonded wheel is designed to be used both as a grinding wheel and as a cut-off wheel on both stainless and mild steel substrates

- Also available with 3M™ Quick Change attachment for improved productivity and throughput

Product Dimensions |

Imperial | Metric |

| Weight | 0.52911 lbs | |

|---|---|---|

| Width | 7 in | |

| Length | 7 in | |

| Height | 1/4 in | |

| Diameter | 7 in | 180 mm |

| Thickness | 1/8 in | 4.2 mm |

| Center Hole Diameter | 7/8 in | 22.23 mm |

Shipping Dimensions |

|

| Weight | 11.49292 lb |

|---|---|

| Length | 7.91339 in |

| Width | 7.91339 in |

| Height | 8.30709 in |

| Color | Black |

|---|---|

| Maximum Speed | 80 mps |

PRODUCT FAQ

-

What is the size of the 3M™ Cubitron™ II Cut and Grind Wheel, 28760?

The wheel size is 7 inches in diameter, 1/8 inch thick with a 7/8-inch center hole.

-

How many Cut and Grind Wheels are there per package?

There are 10 wheels in each inner package.

-

How many packages of Cut and Grind Wheels come in a case?

There are twenty inner packages (totaling to two hundred cut wheels) contained inside one case.

-

. Why should I choose the Cubitron™ II Cut and Grind Wheel over other abrasive discs?

. The Cubitron™ II technology used on this wheel makes it more efficient than competing abrasives. It grinds faster while requiring less pressure which reduces operator fatigue and improves performance enhancing productivity thereby lowering costs since it lasts up to twice as long as conventional ceramic industrial abrasives!

Our 3M™ Cubitron™ II Cut and Grind Wheel is a versatile abrasive disc that can handle multiple tasks without the need for swapping out disks. Unlike other abrasive discs that are designed for just one job, our wheel has a flat, reinforced inner surface that can shape or sand objects, while the thin outer edge can be used to make perpendicular cuts and gouges. This inclusive design eliminates the need for multiple abrasive tools and can help to maximize production.

Precision Shaped Grain3M engineers used proprietary technology to create Precision Shaped Grain by forming triangular structures from 3M™ Ceramic Abrasive Grain. These peaks slice cleanly through metal like a knife through butter, rather than gouging or plowing as traditional abrasives do. The points continuously self-sharpen as they fracture, generating a super-fast cut and reducing heat build-up due to friction. This, in turn, lessens heat-related stress cracks and discoloration.

Operating Requirements- The wheel must have a maximum operating speed greater than or equal to the maximum speed of the power tool used.

- The wheel must be used with a wheel guard that fits the size of the cut-off wheel.