| SKU | 7010373358 |

|---|---|

| Legacy SKU | 70006358603 |

| UPC | 00021200742538 |

| Catalog Number | 476XL |

| Product Number | 476XL |

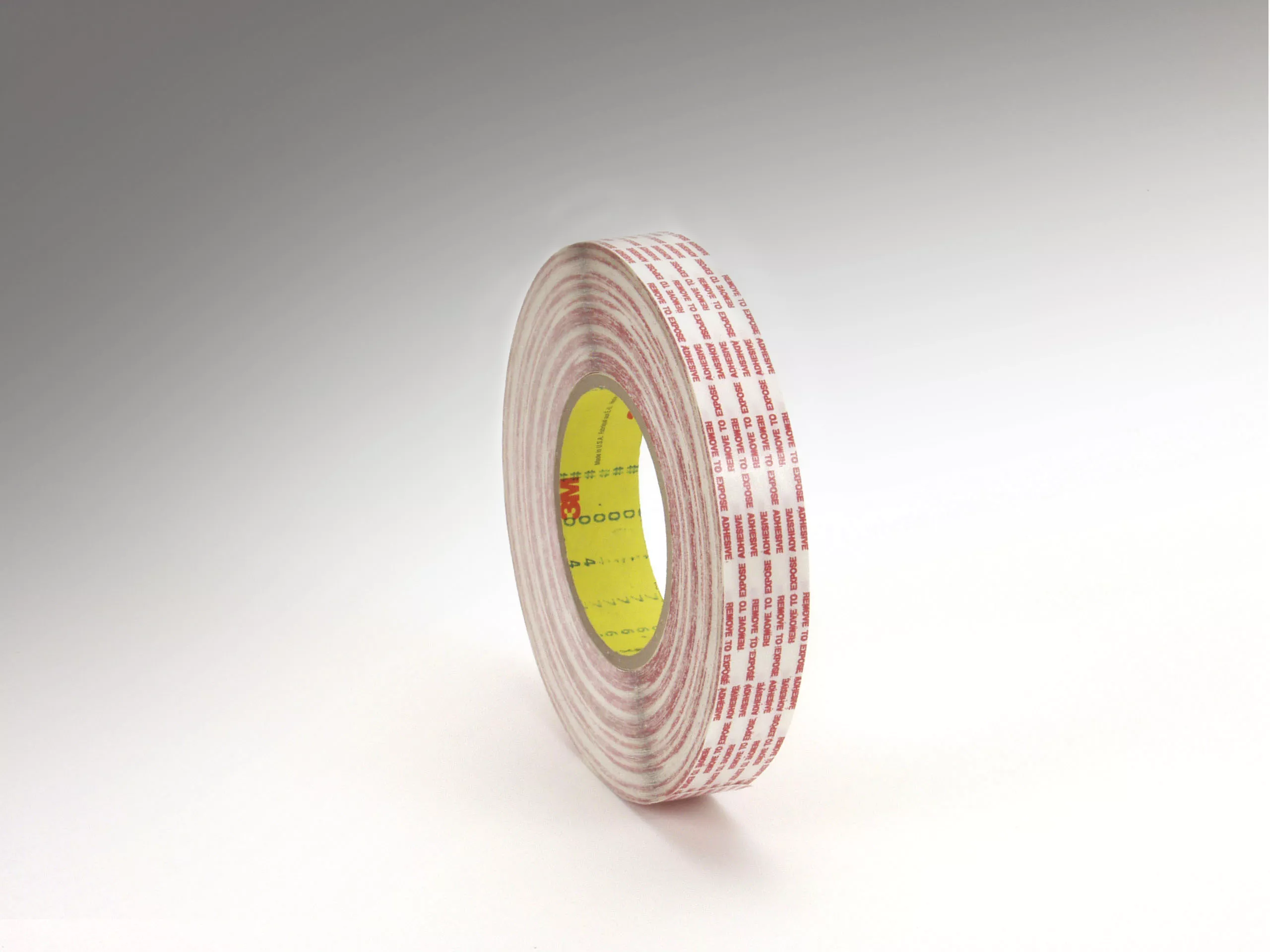

3M Double Coated Tape Extended Liner 476XL is a general purpose tape with a pressure sensitive adhesive mounted on a removable extended paper liner for easy liner starting and removal. It is ideal for a variety of closure applications, point-of-purchase displays and indirect food contact applications.

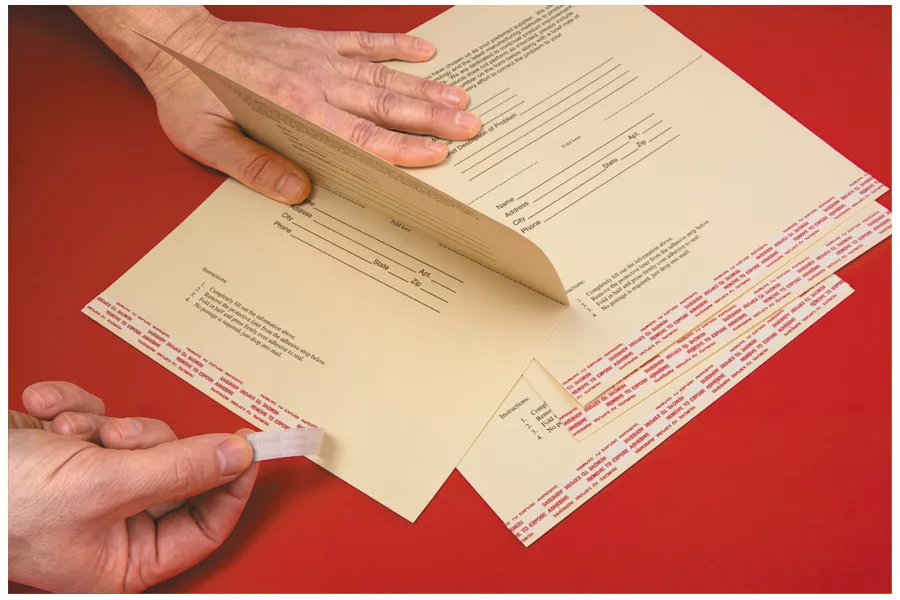

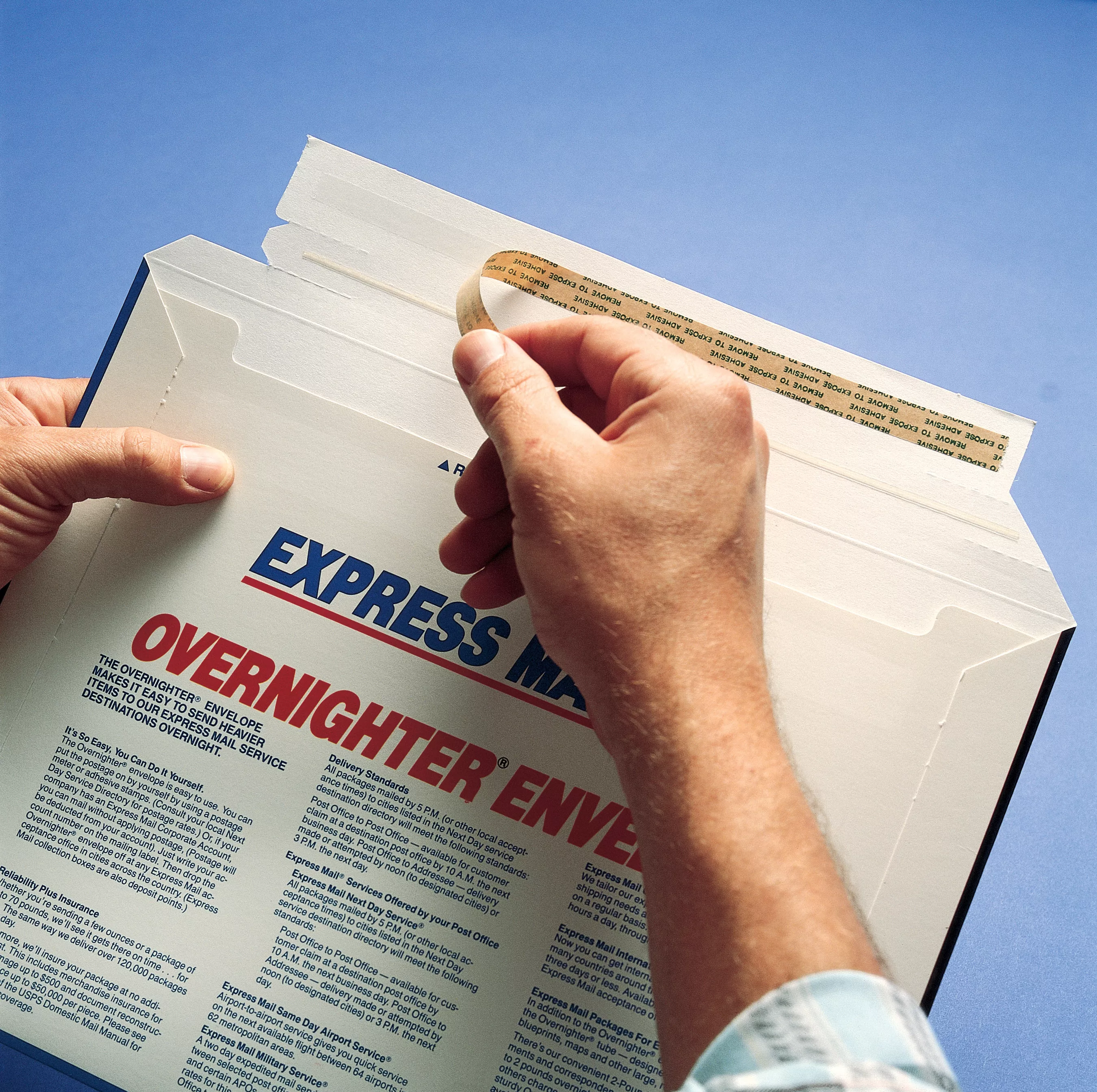

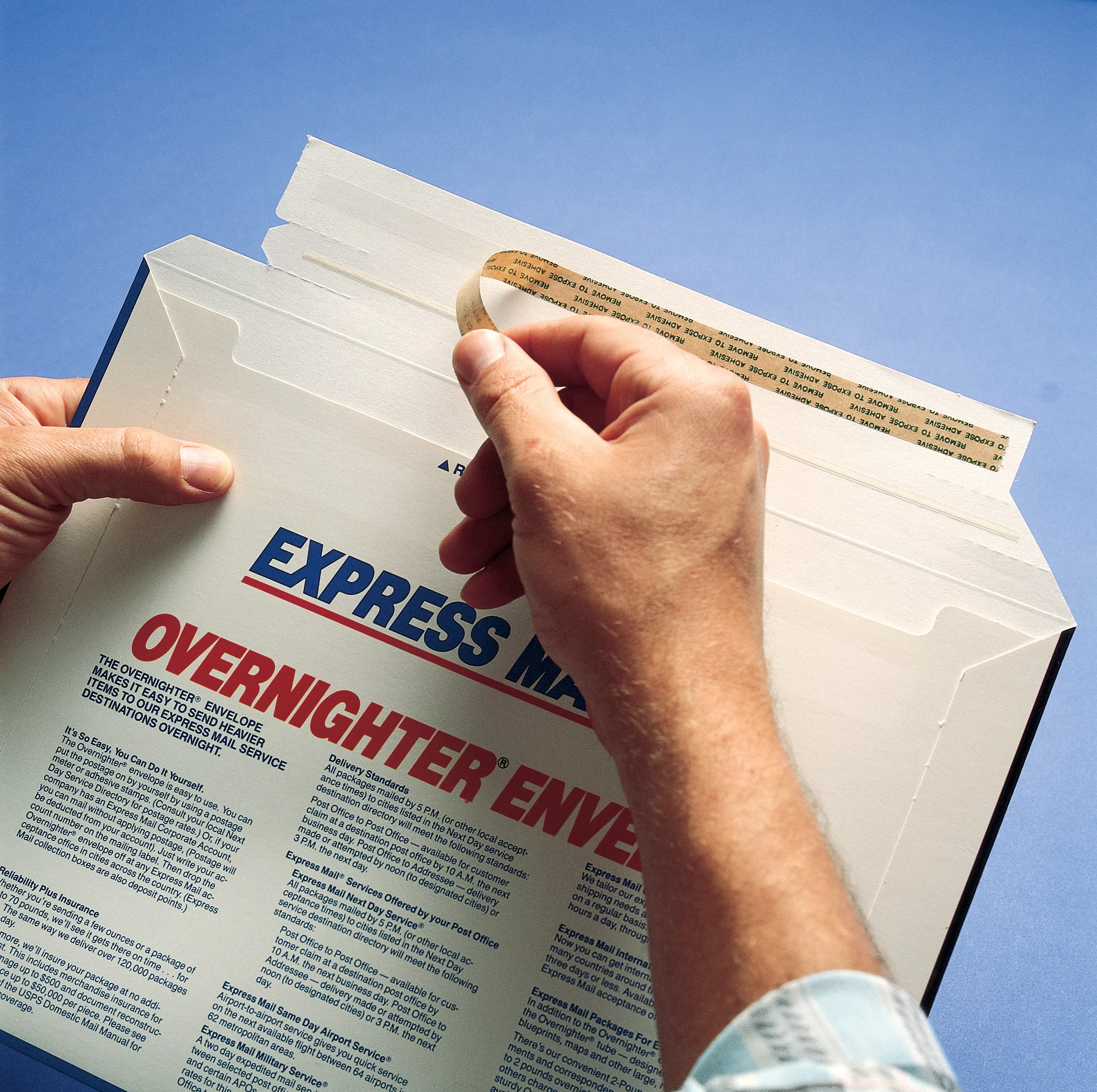

- Ideal for secure closure of shipping boxes, tubes and envelopes

- Dry edge and finger lift edge liners for added user convenience

- Tack free tape roll edges for ease of use and reduced equipment maintenance

- Easy liner starting and removal helps keep jobs running smoothly

- This version of the tape features 3M™ Adhesive 760 and has a 0.08 mil liner

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 6 mil | 0.16 mm |

Shipping Dimensions |

|

| Weight | 40.59813 lb |

|---|---|

| Length | 13.4 in |

| Width | 13.4 in |

| Height | 13.3 in |

| Color | Translucent |

|---|

PRODUCT FAQ

-

What is 3M™ Double Coated Tape Extended Liner 476XL?

3M™ Double Coated Tape Extended Liner 476XL is a pressure-sensitive tape designed with an extended liner for easy liner removal. It comes in a roll format, which makes it very convenient to use.

-

What are the dimensions of the tape and how many rolls come per case?

The tape has a width of 2 inches and length of 60 yards. You get 24 rolls in one case.

-

Is this tape suitable for outdoor use or extreme temperatures?

Yes, this double coated tape can withstand harsh environmental conditions since it's engineered with excellent temperature, UV, and weather resistance properties- making it perfectly adaptable to both indoor and outdoor applications.

-

Can you tell me about its bonding strength?

Definitely! The bond strength offered by this translucent double-coated tape is superior because it provides high initial adhesion while creating an effective permanent bond ideal for general industrial assembly applications like medical devices or automotive parts.

3M™ Double Coated Tapes Extended Liner are constructed with either a polypropylene film or tissue carrier and densified kraft white paper liner that extends beyond the width of the rubber adhesive to provide easy liner starting and removal. The products provide a dry edge or finger lift edge on each side of the tape for easy liner removal.

Recommended Applications- Closure of overnight or express boxes, tubes and envelopes

- Point-of-purchase displays

- Automated tape application equipment

- Mounting promotional items

- Core starting

- Heavy duty sealing

- FDA indirect food contact applications

3M™ Double Coated Tape Extended Liner portfolio offers two rubber adhesive solutions for bonding to many shipping boxes and tubes as well as permanent paper to paper bonding:

- 3M™ Adhesive 760 Synthetic Rubber provides excellent quick stick / initial adhesion and is used on many coated, uncoated and synthetic paper applications. Products featuring Adhesive 760 include: 3M™ Double Coated Extended Liner Tape 476XL

- 3M™ Adhesive 770 Rubber Resin offers high initial adhesion to a wide variety of materials. Products featuring Adhesive 770 include: 3M™ Double Coated Extended Liner Tape 9925XL

In general, double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that can be removed at the time of application or left in place until the joining surfaces are ready to be attached. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in construction, fabrication, arts, and hobby.

Bringing Better Ideas to the Surface through Science and InnovationIn the 3M Industrial Adhesives and Tapes Division, they apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, their technologies help customers like you deliver competitive products to the market faster and more efficiently.