| SKU | 7010369060 |

|---|---|

| Legacy SKU | 70002465063 |

| UPC | 00021200033247 |

| Catalog Number | 415 |

| Product Number | 415 |

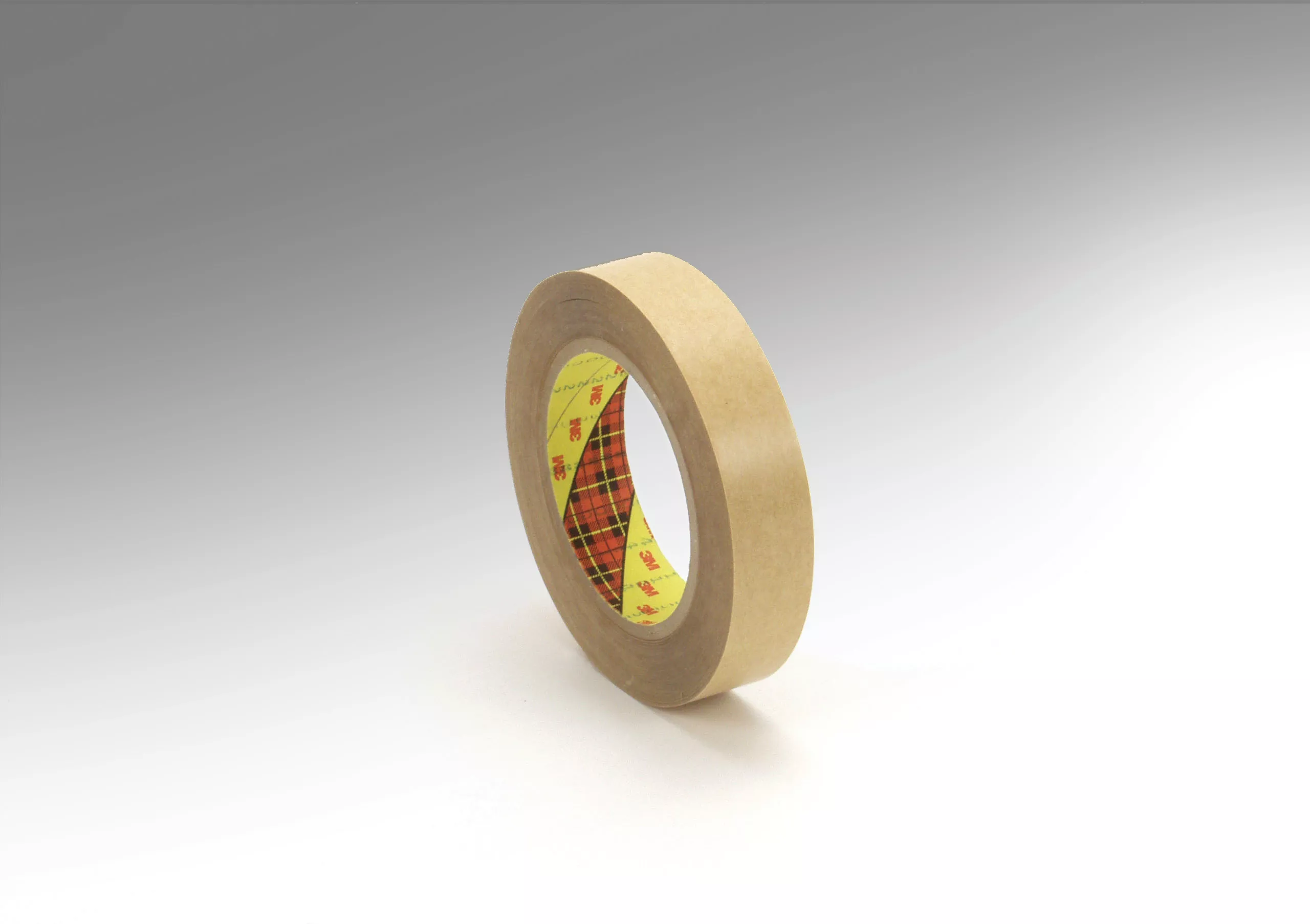

3M Double Coated Tape 415 is a double coated tape that offers a balance of high initial adhesion and good holding power on a variety of substrates, especially paper. Double sided adhesion increases dimensional stability for easy handling, making it an ideal choice for both zero speed and flying splices during printing.

- Ideal for printing applications, with high tack and adhesion to most paper stocks

- Double sided adhesion increases dimensional stability for easy handling during print splicing

- Excellent UV, moderate temperature and good humidity resistance to ensure performance in a variety of situations

- Densified kraft paper liner ensures easy handling

- Good adhesion to a variety of substrates, including low and high surface energy substrates

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 4 mil | 0.1 mm |

Shipping Dimensions |

|

| Weight | 16.32964 lb |

|---|---|

| Length | 10.86614 in |

| Width | 10.86614 in |

| Height | 10.74803 in |

| Color | Transparent |

|---|

PRODUCT FAQ

-

What type of material does 3M™ Double Coated Tape 415 work best on?

3M™ Double Coated Tape 415 works well with a wide range of materials, including metals, plastics, and papers.

-

Can this tape withstand heat and moisture?

Yes! This tape can resist temperatures up to 150°F (66°C), making it ideal for outdoor applications. It also has excellent resistance to solvents and cleaners.

-

How easy is it to apply the tape without causing wrinkles or bubbles?

The adhesive used in this double coated tape allows for smooth application with minimal wrinkling or bubbling. Plus, its high cohesion ensures that your bond stays strong over time.

3M™ Double Coated Tape 415 is a 4.0 mil double coated polyester tape with 3M™ Acrylic Adhesive 400 mounted on a 60. lb densified kraft paper liner. It offers excellent UV resistance, with good temperature and humidity resistance for high performance splicing during rigorous printing applications. This tape will perform well up to 180°F/82°C in the short term, and up to 150°F/65°C for days or weeks. It adheres well to a variety of high and low surface energy substrates including metals, glass, wood, paints and many plastics, as well as most grades of paper, films and foils, and clay coated and corrugated paper stock.

Recommended Applications- High-speed flying splices on most grades of paper

- Zero speed splices on most grades of paper

- Web splicing

- Core starting

- Films and foils

3M™ Adhesive 400 is a medium-firm pressure sensitive acrylic adhesive system. It features an excellent balance of good initial adhesion (quick stick) and good shear holding power. Shear strength is the measure of pull force directed across the bonded surface, forcing the two surfaces to slide over each other. 3M™ Adhesive 400 demonstrates a consistently strong bond across a range of temperatures, up to 250°F/121°C. A thin, tough, polyester film carrier between the adhesive layers improves the handling and strength of the tape. By using a robust 60 lb. densified kraft paper release liner, this tape provides reliable performance for industrial applications such as die-cutting and automated dispensers.

What is Double Coated Tape?In general, double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that can be removed at the time of application or left in place until the joining surfaces are ready to be attached. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in construction, fabrication, arts and hobby.

Bringing Better Ideas to the Surface through Science and InnovationThe 3M Industrial Adhesives and Tapes Division applies the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, these technologies help customers deliver competitive products to the market faster and more efficiently.