| SKU | 7010368748 |

|---|---|

| Legacy SKU | 66000052812 |

| UPC | 00051115376818 |

| Product Number | 727091 |

The Standard Abrasives Surface Conditioning Band is ideal for applying cosmetic grain finishes on Aluminum and Stainless Steel. Made with Surface Conditioning RC material, it has a high rate of cut that helps it finish these substrates swiftly and efficiently.

- Fast rate of cut from unique RC material

- Versatile range of sizes available, uniquely suited to fit where belts cannot access

- Fits snugly over matching rubber drum for ease of use with rotary tool

- Open web is spongy and responsive, minimizing gouging of the part

- Open web is load resistant, prolonging abrasive service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 3.60015 lb |

|---|---|

| Length | 23.30709 in |

| Width | 9.68504 in |

| Height | 5 in |

PRODUCT FAQ

-

What material is the 3M Standard Abrasives™ Surface Conditioning Band 727091 designed to work on?

The abrasive band is designed to work on a variety of materials, including metal, wood, plastics, and composites.

-

How many bands are included in one carton of the 3M Standard Abrasives™ Surface Conditioning Band 727091?

There are a total of 10 bands included in one carton of this product.

-

What does "VFN" stand for in the description of the abrasives band?

"VFN" stands for Very Fine grade, indicating the level of coarseness or fineness of the abrasive for achieving smooth surface finishes.

-

Can I purchase just one case of the 3M Standard Abrasives™ Surface Conditioning Band 727091 if needed?

Yes, each case contains a total of 100 abrasive bands and can be purchased individually as required.

The Standard Abrasives Surface Conditioning Band is a highly effective abrasive product that is designed to reduce surface roughness and uneven edges that often occur when joining parts. It is particularly valuable in industries and trades where welding and fusing are common, such as automotive, aerospace, aircraft equipment and appliance manufacturers, foundries, mold and die shops, and metal fabricators. The band is made from RC material, which allows it to cut quickly while still maintaining a consistent finish. This dual capability of cutting fast and leaving a fine finish helps to reduce the number of finishing steps required, saving valuable time.

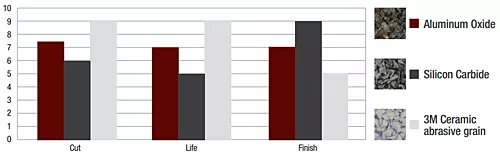

Benefits of Open Web AbrasivesThe Surface Conditioning Band is part of the Standard Abrasives range of products that utilize open web technology. This means that the band has a woven fabric (scrim) embedded in its nylon structure, providing additional strength and durability for edge work, deburring, and efficient blending of all metal types. The band is made from nonwoven nylon web filled with aluminum oxide mineral, which is known for its sharp cutting properties. The resin bond that holds the fibers and mineral together enhances the durability of the abrasive. The aluminum oxide mineral is friable, meaning it fragments under heat and pressure to reveal sharp cutting edges, ensuring a consistent cut throughout the life of the abrasive.

The gaps between the nonwoven nylon fibers allow swarf and debris to escape, preventing the abrasive from getting clogged and maintaining its sharpness for longer. The buoyant and responsive nature of the nylon fibers ensures a consistent cut without gouging or marring the workpiece. This is particularly important when working with fabricated steel parts, as maintaining part geometry is often a top concern. The Surface Conditioning Band is able to conform to the substrate without compromising part geometry, minimizing the need for rework.

Finish Hard-To-Reach AreasThe Surface Conditioning Band is designed to be used with a rubber drum, which is sold separately. It is important for the band and drum to have the same nominal diameter to ensure a tight and snug fit, preventing the band from skidding or bumping along the surface of the workpiece. The drum attaches to a die grinder or rotary tool using a shank. The abrasive is available in a range of sizes to match the unique project needs of users. One of the key advantages of the Surface Conditioning Band is its ability to access and work in tight and hard-to-reach areas where belts may not be able to reach.

In summary, the Standard Abrasives Surface Conditioning Band is an essential abrasive product to have on hand when joining or fusing parts. Its ability to cut quickly while leaving a fine finish makes it highly efficient and time-saving. The open web technology, combined with the use of nonwoven nylon web filled with aluminum oxide mineral, ensures durability, sharpness, and consistent cutting performance. With the ability to conform to the substrate without compromising part geometry, the Surface Conditioning Band is ideal for achieving a fine finish in even the toughest and most hard-to-reach areas.