| SKU | 7010367414 |

|---|---|

| Legacy SKU | 62337885305 |

| UPC | 00021200871801 |

| Catalog Number | 2216 |

| Product Number | 2216NS |

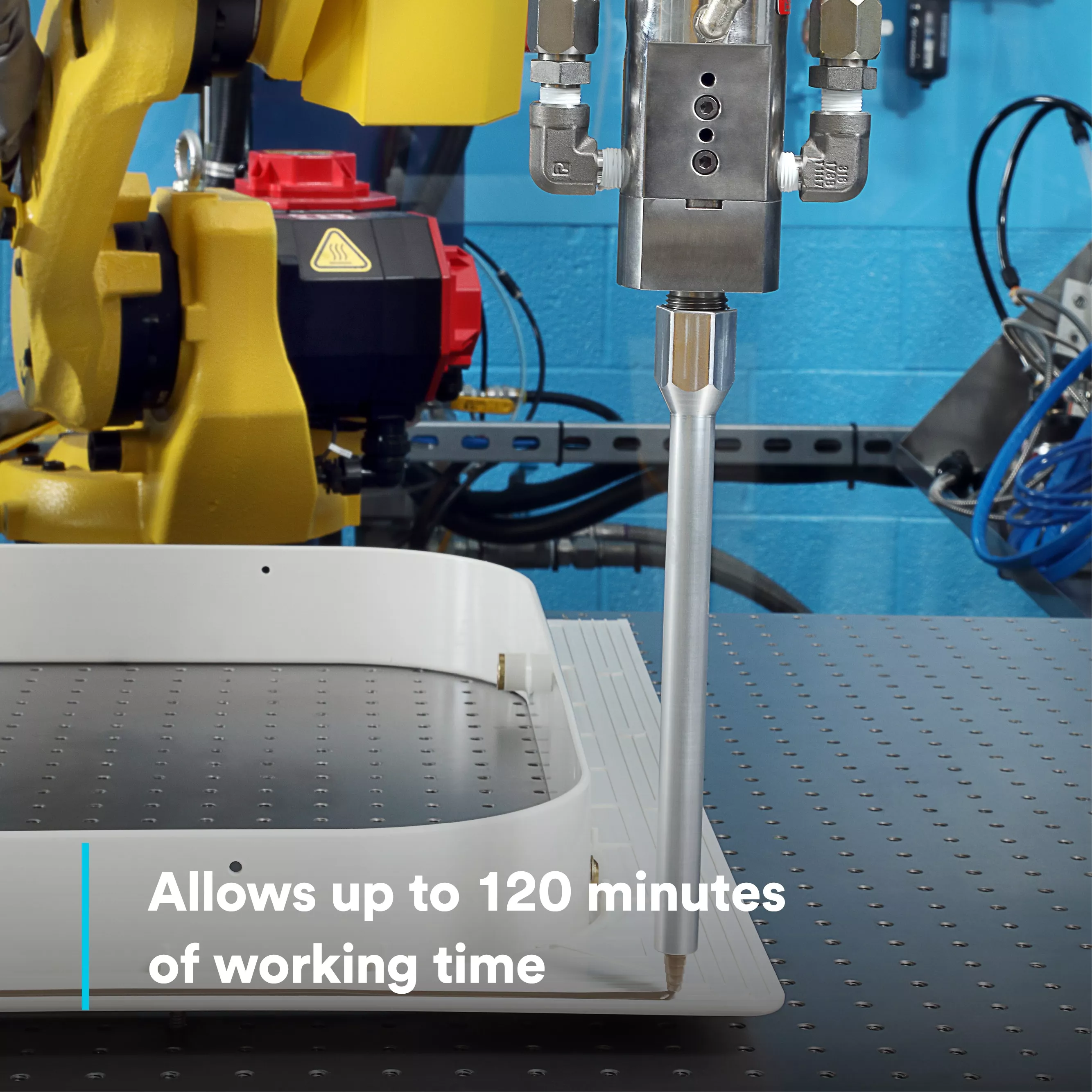

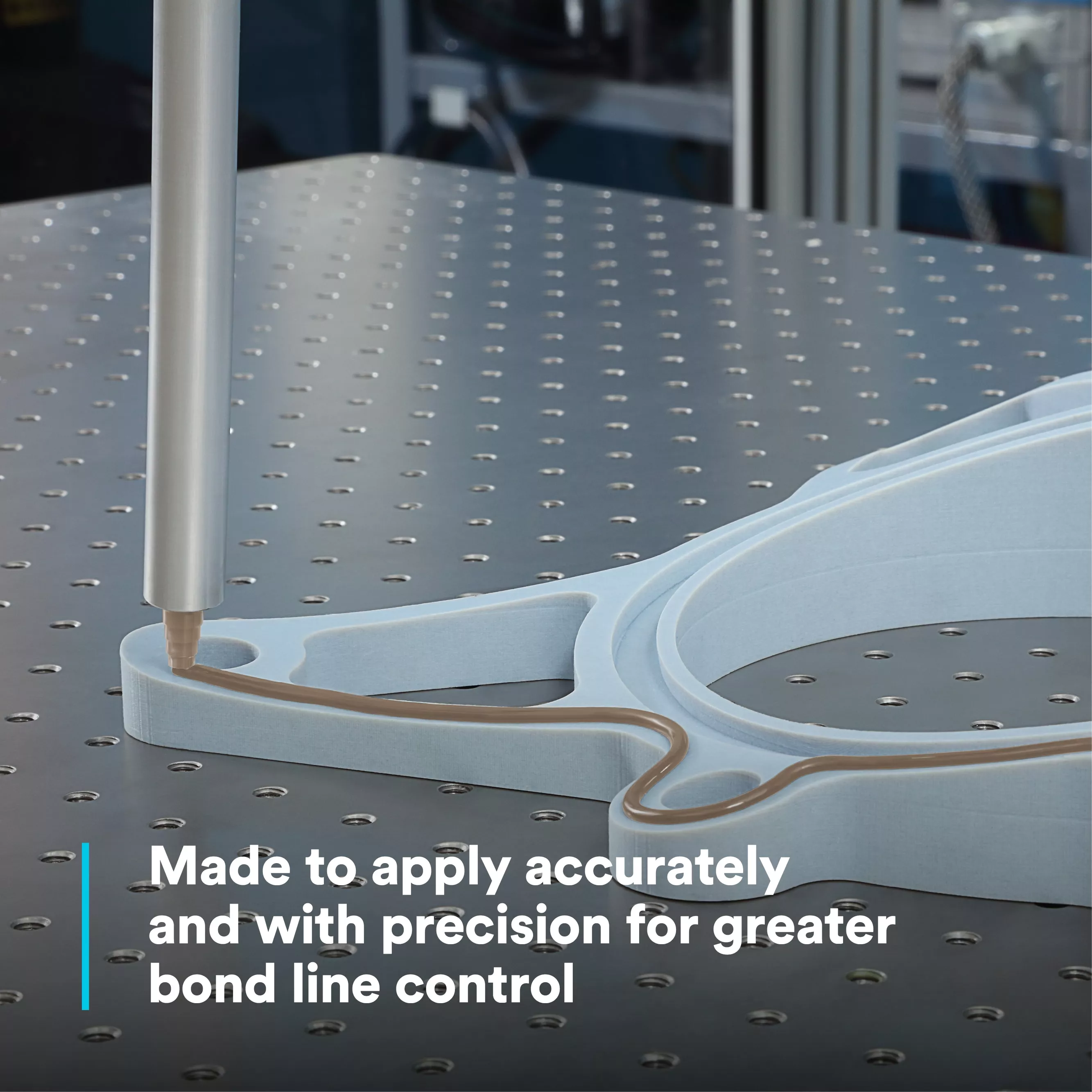

3M Scotch-Weld Epoxy Adhesive 2216 is a high-strength, non-sag formula made to deliver a precision application for greater bond line control. Its long-lasting bond is flexible enough to withstand contraction and expansion, as well as the impact of environmental aging. With up to 120 minutes of working time, it offers ample time to adjust and reposition. Fully cured in 30 minutes at 200 F (93 C), 3M Scotch-Weld Epoxy Adhesive 2216 offers fast-setting results with multiple curing times and temperatures to mee

- MANY SUBSTRATES: Aluminum and other metals, wood, glass, stone, and various plastics

- VERSATILE APPLICATIONS: Bonds metals and other substrates in construction, specialty vehicle, among many others

- LONG-LASTING STRENGTH: Withstands the impact of expansion and contraction

- NON-SAG FORMULA: Made to apply accurately and with precision for greater bond line control

- OPPORTUNITY TO ADJUST: Allows up to 120 minutes of working time

- FAST HEAT CURING: Fully cured in 30 minutes at 200 °F (93 °C)

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 58.52832 lb |

|---|---|

| Length | 14.13386 in |

| Width | 14.13386 in |

| Height | 17.00787 in |

PRODUCT FAQ

-

What is the shelf life of 3M™ Scotch-Weld™ Epoxy Adhesive 2216NS, Tan, Part A?

The shelf life of this adhesive product is two years from the date of manufacture when stored at recommended conditions.

-

Can I use it on metal surfaces?

Yes, you can apply this epoxy adhesive to a wide variety of substrates - including ceramics, most metals and plastics.

-

How much working time does it provide once mixed?

Once the adhesive parts are combined and mixed together in equal parts by weight or volume, they offer approximately 90 minutes of work-life time. This allows ample time for positioning and assembly applications.

-

Does it cure clear or leave a visible residue after curing?

The epoxy cures with minimal shrinkage to form a tough-as-steel bond that will stand up over long periods under extreme loads and environmental conditions. The cured resin offers excellent resistance against impact and vibration material filled without creating any traces / whitish marks.

-

Q: Is this product flammable or toxic in nature?

A:This adhesive part 'A' doesn't fall into any hazardous category as defined by state & federal regulations.However Storage below +5°C may affect Performance characteristics.Retrieve comprehensive safety information prior to usage from SDS (Safety data sheet) available online/usps upon request via your rep/3M distributors & Post one copy near workplace also educating Employees about proper handling procedures

When using a Duo-Pak (DP) size adhesive, rely on 3M dispensing equipment for convenient and accurate metering, mixing and dispensing.

Non-Sag Properties Provides Greater Bond Line Control

3M™ Scotch-Weld Epoxy Adhesive 2216NS is a non-sag version of 3M™ Scotch-Weld Epoxy Adhesive 2216. It is designed for applications where high performance and flexible bonds are required. Its flexibility makes it ideal for applications involving dissimilar surfaces and where differing coefficients of thermal expansion are a consideration. Once fully cured the epoxy maintains an extremely strong bond under expansion, contraction and limited movement while also maintaining a good retention of strength over time and after environmental aging. With a 2:3 mix ratio it is a low viscosity epoxy. It flows smoothly for accurate dispensing. Both the base and accelerator are coded in contrasting colors to ensure you know which half of the product you are using.

Recommended Applications

- Hard disk drive component assembly

- Potting where expansion and thermal changes may occur, such as solar panels and other construction applications

- Military bonding applications, for example bonding parts on movable transports

- Bonding ceramic, most plastics and glass to metal

- Attaching various substrates to masonry and stone

- Excellent for Cryogenic Bonding Applications

3M™ Scotch-Weld Epoxy Adhesive 2216NS is designed to perform under extremely frigid temperatures. Because it can withstand temperatures up to -423°F/-252°C it is ideal for cryogenic bonding applications. At room temperature it offers a 90 minute work life to allow for repositioning and adjustments. It will slowly cure over 7 days, but can be heat cured to reduce this to as little as 30 minutes (at 200°F/93°C.) It has a bonded shear strength that can withstand up to 3,200 psi at 72°F/24°C.

Understanding Epoxy Adhesives

Epoxy adhesives, including 5 minute epoxy are part of the class of adhesives called "structural adhesives," which include polyurethane, acrylic, cyanoacrylate and others. Epoxies are formulated as liquid reactive polymers that undergo a chemical reaction when mixed and then cure to form a solid plastic material. Once the two parts are mixed in their specified ratio, they begin the curing process and offer a limited working time where the adhesive can be applied and the two surfaces positioned as needed. This work life lasts anywhere from a few minutes to several hours. These structural adhesives provide high shear and peel strengths, depending on the formula, and better heat and chemical resistance than other common adhesives. In general, epoxy adhesives have the highest overall strength and offer the best performance and most resistance to high temperatures, solvents and outdoor weathering.

Epoxy adhesive (often referred to as epoxy glue) is widely used in building and home construction; aircraft and automobile manufacturing; bicycle, boat, golf clubs, ski and snowboard assembly as well as a host of home use and other applications. It is used virtually anywhere high-strength bonds are needed along with resistance to environmental conditions. These adhesives are popular for their ease of use, mechanical strength and chemical resistance. Formulations can be created to make epoxy for plastic flexible or epoxy for metal rigid, epoxy resin transparent or opaque, quick setting or slow setting. The versatility with which these adhesives can be formulated helps meet almost any requirement for bonding wood, metal, glass, stone and various plastics.