| SKU | 7010366824 |

|---|---|

| Legacy SKU | 61500295573 |

| UPC | 00048011644240 |

| Product Number | MB-RL |

Scotch-Brite Metal Blending Roll is specifically designed with heat-resistance and finishing properties that support blending and finishing on stainless steel, and doubles up as a good general cleaning sheet roll. Choose this sheet roll to blend surface scratches on many metals, wood and synthetic surfaces.

- Great flexibility and conformability for weld burn removal, blending and satin finishing while leaving a consistent finish

- Nylon web won’t melt on hot welds, allowing blending without waiting

- Silicon carbide mineral in medium grade coarseness works efficiently on weld burns and cleaning stainless steel cooking tops

- Springy fibers conform to irregular surfaces with uniform results

- Load resistant open web construction provides extended use

- Comes in a variety of widths to fit various tools and can be sized according to the application

Product Dimensions |

Imperial | Metric |

| Weight | 1.30514 lbs | |

|---|---|---|

| Width | 14 in | |

| Length | 14 in | |

| Height | 2 in |

Shipping Dimensions |

|

| Weight | 9 lb |

|---|---|

| Length | 14.6 in |

| Width | 14.5 in |

| Height | 13.3 in |

| Color | Gray |

|---|

PRODUCT FAQ

-

What is the Scotch-Brite™ Metal Blending Roll, MB-RL, SiC Medium made of?

The Scotch-Brite™ Metal Blending Roll, MB-RL, SiC Medium is made with premium silicon carbide abrasive mineral for exceptional durability.

-

Can this product be used to remove rust and corrosion from metal surfaces?

Yes! The Scotch-Brite™ Metal Blending Roll can effectively remove rust and light corrosion from a variety of metals.

-

How long does it last before needing replacement?

The longevity varies depending on usage conditions but this blending roll has excellent resistance to wear due to its tough material composition; as such consistent performance throughout its life can be expected.

-

. Is the medium grit aggressive enough for heavy duty application or ideal for softer metal finishing applications only?

. There are different grades available but the medium grade offers a great balance between fast cut rate thereby suitable even for heavier oxide/rust removal while still leaving a finer finish than most conventional coarse abrasives bring.

-

. Are there recommended safety precautions that come with using this product?

. Yes, we recommend following established safety practices especially when working with power tools (such as harnessing pieces firmly in place). We encourage consultation of the MSDS brochure and following best practice guidelines including wearing appropriate protective equipment (eye protection featured heavily) during use too

This gray open-web sheet roll is constructed with medium grade silicon carbide grain bonded onto tough, conformable nylon strands to help achieve a smooth, clean satin finish. The nylon fibers resist heat and won't melt on hot welds, so blending immediately after welding when desired is possible. For efficient blending on contoured or irregular surfaces, the Metal Blending Roll has a high level of flexibility that produces consistent results use after use. This long-lasting sheet roll is both heat- and load-resistant to stand up to prolonged use. The extended life and efficient performance of durable Scotch-Brite material means operators can complete more pieces in a shorter amount of time.

Variable SizingScotch-Brite™ Metal Blending Sheet Rolls comes in a range of widths to fit many different tools. Sheets can be cut to size depending on the tool or for hand sanding, and the flexible sheets can be rolled or folded to reach into tight areas for blending or general cleaning.

Silicon Carbide for a Fine FinishThe Scotch-Brite Metal Blending roll contains silicon carbide abrasive mineral, a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep. While it breaks down faster than aluminum oxide, it produces a superior finish.

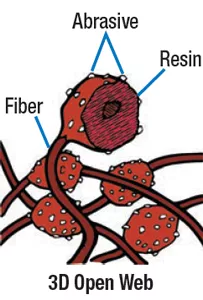

The Scotch-Brite™ AdvantageScotch-Brite™ industrial abrasives are unique surface conditioning products with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product.

- The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

- Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life.

From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.