| SKU | 7010366638 |

|---|---|

| Legacy SKU | 61500183407 |

| UPC | 00048011325958 |

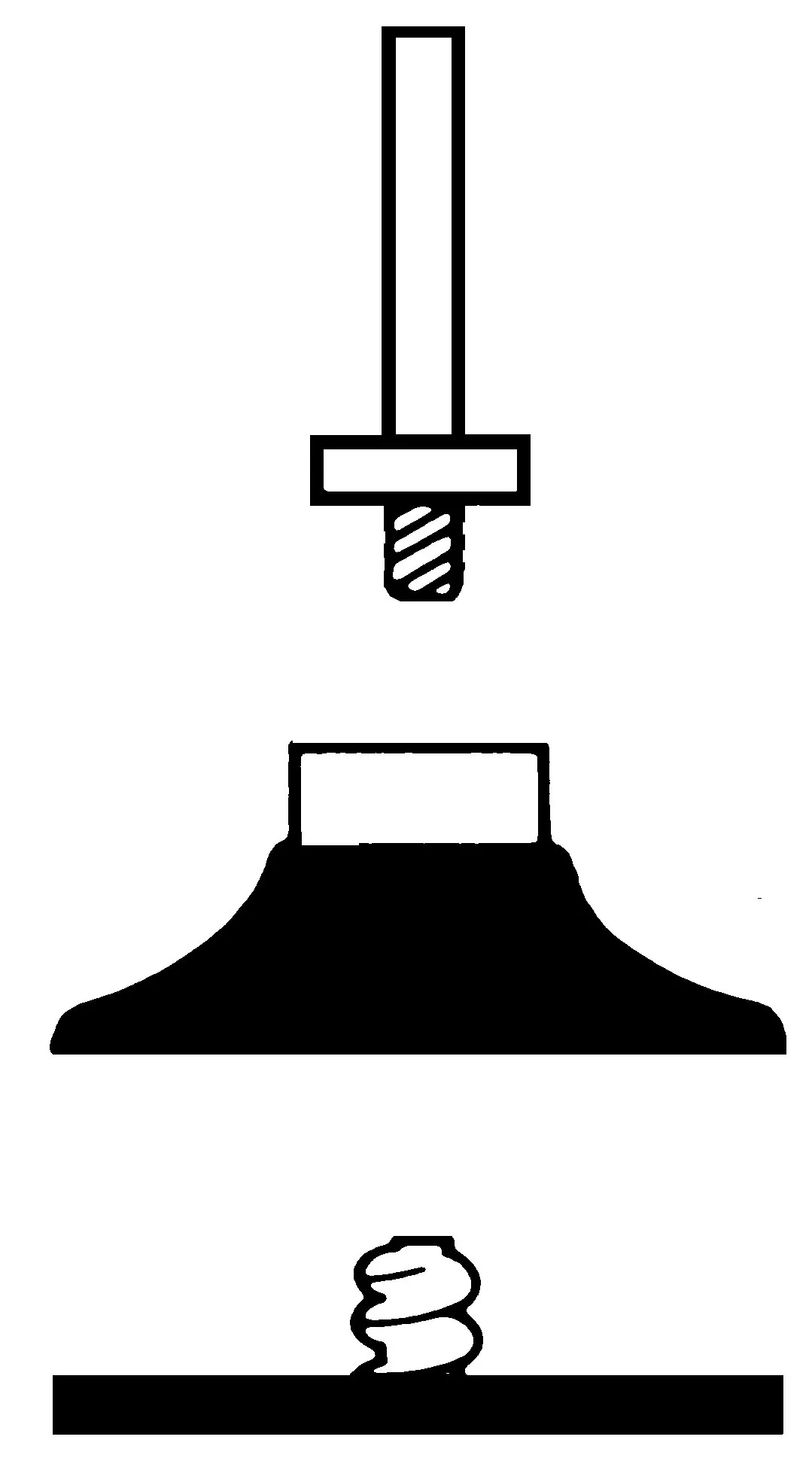

Scotch-Brite Roloc Surface Conditioning Low Stretch Disc is a non-woven abrasive product used for cleaning, finishing, blending and deburring applications. This versatile disc has the advantages operators have come to expect from Scotch-Brite and Roloc products, including responsive open web and a speedy attachment. The low stretch backing gives the disc added stiffness.

- Roloc™ attachment for quick, easy disc to tool attachment

- Open web responds to surface irregularities without compromising the geometry the part

- Open web is load resistant, minimizing build up and prolonging abrasive life

- A great multi-purpose abrasive for many metals

- Low stretch backing gives the disc added stiffness

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 2.658 lb |

|---|---|

| Length | 10.7 in |

| Width | 10.7 in |

| Height | 5.6 in |

| Thread Size | Non Pertinent |

|---|

PRODUCT FAQ

-

What is the diameter and item code of the Scotch-Brite™ Roloc™ Surface Conditioning LS Disc TS that you have in stock?

The diameter of our Scotch-Brite™ Roloc™ Surface Conditioning LS Disc TS disc is 2 inches and its item code is SPR 017218A.

-

What kind of surface conditioning can I expect from these discs?

You can expect light to medium duty surface conditioning from our Scotch-Brite™ Roloc™ Surface Conditioning LS Disc TS, which will remove rust, paint, oxides and coatings.

-

How many discs are included per case for this product your website mentions – '200 per case?'

Yes, there are 200 pieces of Scotch-Brite™ RolocTM Surface Conditioning LS Discs available in each case ordered by you.

What sets the Scotch-Brite™ Roloc™ Surface Conditioning Low Stretch Disc apart from other discs is its unique combination of mineral, backing, and overall abrasive construction. This disc is available in coarse (CRS), medium (MED), and very fine (VFN) grades, allowing operators to choose the right grade for their specific application. The Scotch-Brite open web design resists loading for longer life and consistency, and offers the flexibility needed to achieve consistent results on contoured surfaces and edges without compromising the geometry of the workpiece. This means greater productivity and lower inventory costs. The disc is engineered to perform high initial and extended rates of cut, while maintaining superior edge durability. It is an excellent starting point for working on intricate details, contours, and edges to remove surface imperfections, grindlines, mill, and other marks.

3M™ Roloc™ Attachment Expedites Disc SwapsThis disc also features a 3M™ Roloc™ attachment, which helps expedite disc to tool attachment. Roloc™ discs fasten to Roloc™ backup pads (sold separately) with a simple 1/2 turn. Subsequently, the backup pad attaches to the tool, be it a disc or die grinder. Roloc™ discs were engineered to make disc to tool attachment swift, easy, and more efficient.

The Many Benefits of Scotch-Brite™ AbrasivesScotch-Brite™ industrial abrasives are unique due to their nonwoven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite™ products may enhance productivity while reducing the need for cleaning chemicals and wire brushes. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite™ abrasives work fast and deliver consistent results, part after part.

- Unique nonwoven technology

- Spring-like fibers respond to contours

- Effectively removes unwanted burrs, soils, and contaminants

- Maintains geometry of workpiece

- Reduces rework and boosts productivity

- Gaps in web allow swarf to escape

- Fibers continually break down with use to reveal fresh mineral

- Enhances productivity while reducing need for cleaning chemicals and wire brushes

- Works fast and delivers consistent results, part after part